- MEP coordination in BIM prevents rework and delays by detecting and resolving inter-disciplinary interferences between mechanical, electrical, and plumbing.

- The MEP coordination process ensures greater constructability and a unified system that fits perfectly within the architectural and structural layout.

- Outsourcing MEP coordination services to the right partner can reduce costs, save valuable time, and ensure faster MEP fabrication and installation.

Table of Contents

- How MEP coordination services support building design and construction

- 4 Benefits of MEP coordination services for BIM/CAD firms

- Common causes of poor MEP coordination in BIM

- What are the best practices in the MEP coordination process?

- MEP BIM coordination services success stories

- Impact of AI/ML and Generative design on MEP coordination

- How to select the right MEP coordination partner

- Wrapping up

Modern construction projects involve levels of complexity that are inconceivable to handle with traditional MEP processes and tools. Using 2D drawings as a starting point by itself can lead to errors. Due to the sheer size of a project, thousands of drawings can easily be mismanaged or misplaced. Furthermore, 2D drawings are incapable of identifying clashes and resolving them, and fail to offer the visualization needed by teams and stakeholders.

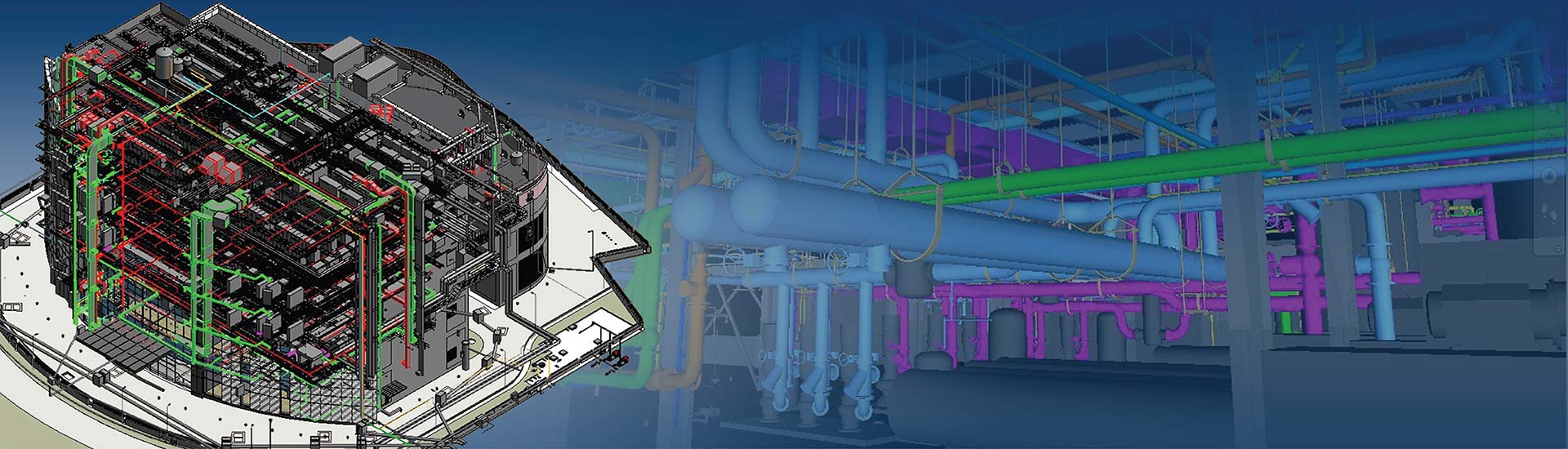

MEP coordination services use BIM processes and tools to integrate designs of multiple disciplines, including mechanical, electrical, and plumbing, into a single 3D model. These services help BIM professionals and building engineering consultants improve system routing and ensure swift on-site installation processes. Such a specialized service firm enhances overall project effectiveness when acting as a partner.

In the following article, we have outlined the significance of MEP coordination services in modern-day construction. We have taken a look into the benefits of MEP BIM coordination services, from factors that often lead to inaccurate coordination to best practices that ensure precise MEP coordination.

How MEP coordination services support building design and construction.

The MEP coordination process requires separate 3D models from various trades, including mechanical, electrical, and plumbing. There are various components in these systems, including HVAC, electrical, and plumbing. Further breaking down, these components include ductwork, air handling units, exhaust systems, lighting systems, fire alarms, security systems, drainage, stormwater, gas piping, and other units.

BIM processes and tools integrated within MEP coordination provide a significant workflow boost. Using capabilities like real-time visualization, collaboration, and clash detection reinforced by tools like Revit and Navisworks takes MEP coordination to another level. Working on updated files stored on collaboration platforms like BIM 360 makes sharing and access easier, while extracting accurate and information-rich fabrication and installation drawings from the 3D model itself ensures fabrication and installation precision.

When it comes to project-wide MEP coordination, various participants are involved in the process. These include architects, MEP designers, structural engineers, building engineering consultants, and trade-specific contractors. All of these stakeholders collaborate in the preconstruction stage to make sure every MEP system is aligned correctly and is constructible on the project site.

4 Benefits of MEP coordination services for BIM/CAD firms.

Building engineering consultants and BIM/CAD firms need MEP coordination services to achieve project accuracy, efficiency, and quality. Integrating MEP coordination services within your present workflows delivers a wide spectrum of advantages, which include:

1. Error reduction and collaboration to improve project efficiency

Efficiency is an important aspect of a construction project and requires attention at various phases. Collaboration and error reduction are critical parameters that can elevate project efficiency for building engineering consultants.

-

Project teams can communicate better using a centralized platform.

BIM tools offer project stakeholders a unified platform like Revit and Navisworks, to create and audit 3D models. Users can share and access files and track updates from collaboration platforms, like BIM360. Files visualized on a unified platform speed up the communication process.

-

Clashes detected early reduce delays.

Coordinating a single 3D model for mechanical, electrical, and plumbing in the preconstruction stage minimizes delays. Users can coordinate separate 3D models in Navisworks, identify, and resolve clashes, and generate detailed clash reports from the tool itself. This is where MEP clash detection automation plays a crucial role, enabling faster resolution cycles and improving design accuracy across multidisciplinary teams.

Quick clash detection leads to faster design adjustments, prevention of rework during actual construction, and avoidance of additional costs. Clash detection in 3D helps stakeholders visualize every MEP component in an immersive setting, which ensures all the MEP systems align and fit together.

-

Visualizing the entire MEP system in a digital space improves scheduling.

Tools like Navisworks provide accurate and realistic visualization of construction scheduling using TimeLiner. Users can include resources, equipment, surrounding areas, and other elements with the 3D model to create a complete snapshot with each schedule for every stage. This supports building engineering consultants’ plans and improves logistics based on the coordinated BIM model.

2. Conflict reduction ensures cost savings

As discussed above, clash reduction leads to lower rework, but it also lowers project costs, as on-site work happens faster.

-

Reducing reworks during preconstruction expedites project completion.

Faster project completion can be achieved through rework prevention. Clashes identified and resolved early reduce site rework. Flagging design flaws with the entire team collaborating on a single tool during preconstruction gives them a clear idea of quick MEP modifications that need to be carried out. Each team participant from various trades is given a task to resolve the clashes and coordinate the model accordingly.

-

MEP design coordination prevents on-site conflicts.

On-site conflicts lead to critical project failures, causing delays and cost overruns. Coordinating various MEP models into a single model reduces the chances of on-site changes. Frequent design reviews using a digital representation with every team present ensure accurate documentation and communication. Collaboration between teams facilitates faster decision-making, which leads to expedited work on the site.

-

Accurate QTOs from coordinated MEP models ensure budget compliance.

A coordinated 3D MEP BIM model provides BIM engineering consultants with accurate quantity takeoffs. The 3D model includes every bit of detail on dimensions, materials, specifications, date of manufacture, etc. Users can extract exact MEP component quantities and materials required to manufacture MEP systems. This ensures MEP systems are built and installed within the planned budget.

3. Visualization and code compliance lead to greater site safety

Integrating global and standardized fabrication and installation codes into the coordinated 3D MEP model ensures faster project approvals and a safer construction site.

-

3D-coordinated MEP models enriched with codes improve compliance and facilitate inspections.

Coordinated 3D MEP models are compliant with codes like IMC, NEC, IPC, NFPA, and IECC to ensure MEP design is accurate and energy efficient. It also helps speed up approvals from local authorities, as the model conforms to required standards. Compliance with global standards also ensures fabrication clarity and precision.

-

Visualizing hazardous areas in the 3D MEP model reduces safety risks during construction.

Construction projects consist of spaces or areas that are hard to reach or deemed hazardous. These include excavations, moving elements, working in higher areas, combustible materials, and flammable gases. Coded 3D models provide a detailed visualization of these areas for onsite personnel to work in a safety net and lower risks.

-

Coordinated MEP systems enhance fire safety for building occupants.

A coordinated MEP system improves fire safety through the design and installation of fire protection systems. These codes cover a large spectrum of aspects, including fire resistance, material specifications, smoke detection systems, alarms, sprinklers, etc. Compliance with codes like NFPA, ICC, ISO, and IEC ensures building and occupant safety.

4. Accurate MEP design improves performance and quality

Extracting fabrication and installation drawings from the coordinated MEP model enhances MEP system performance and manufacturing quality.

-

Calculating the right energy values for mechanical/HVAC systems ensures occupant comfort.

The use of built-in features in Revit helps teams calculate precise energy values for HVAC systems. Calculating accurate HVAC loads and running realistic simulations in tools can improve occupant comfort. Revit offers strong energy analysis features to simulate building performance. Integrating with tools like Autodesk Insight, users can create comprehensive energy models that include insulation and thermal mass, integration with EA tools, heating, and cooling load calculations, zone condition analysis, and cost analysis.

-

Using Revit libraries with actual materials and specifications in the 3D model leads to greater MEP efficiency.

Revit families are powerful features offered by Revit, allowing parametric and realistic MEP libraries to be included in the 3D model for ductwork, electrical systems, piping, and fire protection equipment. Utilizing these libraries ensures fabrication is accurate, as they encapsulate precise dimensions, material use, specifications, etc.

MEP design conflicts stalling your project?

Our MEP coordination services eliminate clashes, clarify systems, and keep your project moving forward.

Common Causes of Poor MEP Coordination in BIM

Inaccurate MEP design coordination can lead to catastrophic MEP system failure for building engineering consultants, BIM professionals, and occupants. It also creates rework possibilities that cause cost and time overages. Listed below are observed factors that contribute to inaccurate MEP design coordination.

-

Collaboration failure.

The inability to collaborate with other teams or work in silos creates disconnected workflows that lead to inaccurate coordination.

-

Technology underutilization.

Not utilizing the required software tools or platforms can lead to interoperability issues, gaps in accurate MEP coordination, and misunderstandings between various teams.

-

Inexperienced personnel.

People lacking expertise in MEP coordination are unable to comprehend its significance in construction. These personnel are not able to utilize all the capabilities of tools like Revit and Navisworks. Furthermore, failing to apply workflows based on BIM LOD levels can cause catastrophic issues during MEP system manufacturing and installation.

-

Inaccurate documentation.

As discussed above, documentation is derived from the 3D BIM model itself, but if the 3D model is plagued by errors and issues, it would lead to inaccurate QTOs, BOQs, fabrication, and installation drawings.

What are the best practices in the MEP coordination process?

Best practices in MEP coordination ensure the process is seamless and accurate. Coordinated correctly, MEP systems can align perfectly with architectural and structural design. It also reduces rework and promotes faster manufacturing and installation.

- Involve MEP coordinators: Early involvement of MEP coordinators supports quick clash identification and resolution to reduce rework and delays.

- Deploy MEP personnel: Enable an experienced team of MEP professionals to achieve effective collaboration, accurate design, and error-free installation.

- Use MEP coordination tools: Use BIM coordination tools to visualize and simulate MEP systems for spatial coordination and design enhancement.

- Conduct coordination meetings: Run regular meetings to understand progress, resolve issues and ensure every participant is aligned with project goals.

- Monitor updates: Continuously monitor design and construction updates with cloud-platforms to streamline processes and utilize updated data.

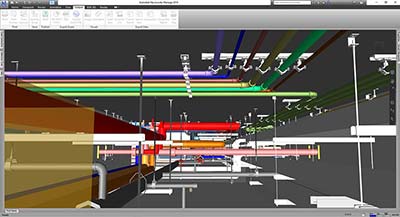

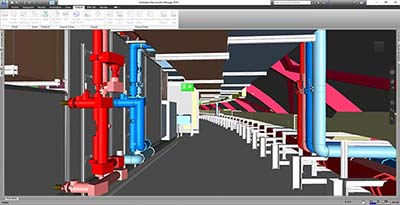

Coordinated and clash-free MEPF models for a hospital project in Ireland save time.

An engineering contracting company partnered with HitechDigital for a hospital project in Ireland. The client required a coordinated and clash-free 3D model. As 2D and markup drawings were provided by the client, it came with a share of challenges, including coordination complexities and quality-sensitive deliverables. Deviations or errors could lead to delayed schedules and material waste.

Detailed and clash-free 3D MEP models were created from the client’s input. Once created, the model was sent for clash detection and resolution, followed by robust QA processes. Once done, the client was able to extract shop drawings, BOQs, sections, and drawings, including spool, module, schematic, etc. All project files were stored on BIM360 for quick access, sharing, and modifications.

Handing over the deliverables to the client led to,

- Swift installation of MEP elements with precise module, spool, and shop drawings.

- 98% FTR deliverables.

- Greater customer satisfaction at every project stage.

3D MEP coordinated corridor section model

3D MEP coordinated corridor section model

3D MEP coordinated model for Plant Room

3D MEP coordinated model for Plant Room

3D Revit MEP coordinated model for Plant Room

3D Revit MEP coordinated model for Plant Room

Impact of AI/ML and Generative design on MEP coordination

AI/ML and generative design would extend the capabilities of MEP coordination within the Revit and Navisworks framework. It would support users in achieving greater accuracy, driven by quick implementation. Generative design, with its advanced algorithms, would produce multiple prototypes for complex projects, ensuring swift decision-making.

-

AI-based interference detection and resolution in MEP design.

AI-driven clash detection and resolution would use rule-based ML algorithms. Integrating AI with coordinated MEP models can leverage tools like spatial rule sets and geometrical analysis to check for interferences. ML algorithms would classify interferences and their severity while calculating solutions to reroute or resize solutions driven by design intent or priorities to achieve faster implementation.

-

Exploring multiple MEP design layouts with generative design.

Generative design utilizes various algorithms to define the project scope, including duct runs, lower energy loss, etc. It also defines various constraints like fire codes, ceiling areas, etc. Users can create prototypes with optimization strategies, including gradient descent and genetic algorithms. Layouts can be assessed through load analysis, CFD, etc., for faster decision-making.

How to select the right MEP coordination partner

Working with the right MEP coordination partner ensures a greater project impact with time and cost savings and high-value FTR deliverables. Mentioned below is a sure-shot checklist to select the most appropriate MEP coordination partner.

Verify track record in MEP coordination.

Verifying the past performance of an MEP coordination partner from their clients or various digital sources can help you assess various parameters, including success rate, professionalism, completion time, working costs, etc.

Understand their proficiency in technology utilization.

Understanding their expertise in process and technology utilization would bring greater clarity to the ability to execute complex projects. Furthermore, utilizing advanced automation within tools like Revit would help expedite the 3D MEP coordination process. It also ensures effective and efficient results during handovers.

Assess their capabilities to employ skilled personnel.

The presence of skilled personnel is one of the most crucial aspects of choosing the right MEP coordination partner. If a provider employs skilled personnel, then it increases the reliability and comfort factor for clients to be repeat customers with other projects as the end result is impactful and driven by high-quality deliverables.

Ensure that they have a thorough QA process in place.

Deploying a robust QA process in place confirms the accuracy and validity of the MEP-coordinated model. This leads to high-quality results for clients and sustainable construction, which are cost-effective and aligned with planned timelines.

Conclusion.

MEP coordination services will continue to provide significant value for Building Engineering Consultants and BIM/CAD professionals through clash-free MEP models. With multiple processes and a comprehensive toolset driven by automation, MEP coordination would provide greater visibility and stakeholder coordination to resolve present-day construction challenges. Partnering with the right solution provider for MEP design services would ensure problem-free onsite installation and minimal rework.

Reduce rework by identifying MEP clashes during preconstruction stage.

Connect with our BIM coordination experts for end-to-end MEP integration.