- MEP clash detection in BIM prevents costly rework and delays by identifying design conflicts early, keeping projects on budget and schedules on track.

- Integrated clash detection streamlines coordination by resolving conflicts digitally, optimizing prefabrication, and ensuring seamless trade execution before construction begins.

- Partnering with a clash detection expert enhances accuracy and efficiency, reducing project risks, minimizes costly modifications, and improves overall profitability through precise, well-coordinated construction workflows.

Table of Contents

Construction projects depend on precise coordination between multiple disciplines, especially mechanical, electrical and plumbing (MEP) systems. When these systems are not properly aligned, the result is unexpected clashes that cause costly reworks, scheduling delays, and resource inefficiencies.

For a general contractor, MEP engineer, BIM manager or project owner, these challenges are all too familiar. A misalignment discovered on-site means halting work, revising drawings, reordering materials, and pushing back deadlines—all of which add up to significant financial losses.

This is where MEP clash detection in Building Information Modeling (BIM) changes the game. By identifying conflicts before construction begins, teams can eliminate design errors, optimize workflows, and prevent costly disruptions. This approach not only saves time and money, but also enhances collaboration between disciplines, resulting in more efficient project execution.

Understanding MEP clash detection

What is MEP Clash Detection in BIM?

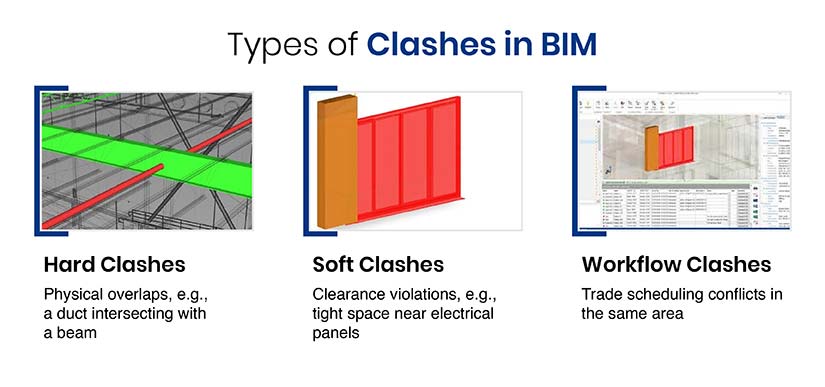

MEP clash detection is the process of identifying, analyzing and resolving conflicts between different building systems in a 3D BIM environment. These conflicts can be categorized into three main types:

- Hard clashes occur when two physical components overlap in the same space, such as a duct intersecting a load-bearing beam. These are critical issues that must be resolved before construction begins.

- Soft clashes involve spatial tolerances, meaning that while elements do not physically overlap, they may be too close to function properly. For example, an HVAC unit might lack the required clearance for maintenance access.

- Workflow clashes arise from scheduling conflicts when project timelines are not properly coordinated. If electrical wiring is scheduled for installation before drywall or HVAC components arrive before their structural supports are in place, delays are inevitable.

By using BIM coordination software like Autodesk Revit, Navisworks, and BIM 360, teams can detect and address these clashes in the design phase long before they turn into costly on-site problems.

Common causes of MEP clashes in construction

Misalignment Between Disciplines: Poor integration of architectural, structural, and MEP designs leads to conflicts like HVAC ducts interfering with beams or plumbing lines overlapping electrical wiring. Regular BIM coordination meetings with stakeholders between architects, engineers and contractors prevent these inconsistencies with early clash detection.

Insufficient Level of Detail (LOD): If MEP components are modeled with vague dimensions, they may not fit as intended. Clearly defining level of detail (LOD) requirements at each project stage reduces the risk of clashes.

Scheduling and Material Delivery Issues: Delays in material deliveries or improper sequencing can disrupt planned workflows. If MEP systems are installed before structural elements are ready, clashes occur. Proper scheduling prevents these conflicts.

How MEP clash detection in BIM saves costs

Reducing rework costs

Rework is a major cost driver in construction, often accounting for up to 34% of total project expenses. When clashes are discovered during installation, teams must stop work, remove installed components, and redesign the layout, causing budget overruns and lost productivity.

With BIM-based clash detection, these issues are identified before materials are ordered or workers set foot on site, preventing expensive corrective actions.

Minimizing change orders

Change orders are one of the biggest sources of budget inflation in construction projects. Studies show that projects using BIM experience 42% fewer change orders because potential conflicts are identified in the pre-construction phase, avoiding last-minute redesigns and additional labor costs.

Cost savings from prefabrication & preconstruction planning

Early clash detection enables MEP contractors to prefabricate components with precision, reducing on-site labor and material waste. With a coordinated BIM model, teams can:

- Prefabricate ductwork, piping, and electrical components to exact specifications

- Reduce the number of hours spent on-site, making adjustments

- Optimize logistics and material procurement, ensuring that only necessary materials are ordered and delivered

These efficiencies contribute to lower overall project costs and faster completion times.

How MEP clash detection in BIM saves time

Faster project completion

Unresolved clashes can add weeks—or even months—to a project timeline due to onsite troubleshooting, redesigns, and installation delays. By eliminating these bottlenecks early, clash detection ensures a smooth, uninterrupted construction process.

Improved scheduling and sequencing

A clash-free model enables better coordination between trades, reducing instances in which one team’s work is delayed because another’s installation conflicts with the design. Clash detection allows project managers to:

- Align trade schedules to prevent workflow disruptions

- Minimize coordination meetings and back-and-forth revisions

- Ensure that all materials and systems are installed in the correct sequence

Enhanced decision-making through cloud collaboration

Cloud-based platforms like BIM 360 and Autodesk Construction Cloud allow teams to work from a single, up-to-date model, facilitating:

- Faster approvals from stakeholders

- Real-time issue tracking and resolution

- Instant updates on design modifications, preventing miscommunication between teams

Benefits beyond cost and time

1. Enhanced safety on the job site

Undetected clashes in MEP systems can lead to hazardous conditions, increasing the risk of workplace accidents. BIM-powered clash detection helps:

- Identify overlapping fire protection systems that could block emergency exit paths (also known as egress routes). These are designated pathways that allow building occupants to evacuate safely in case of fire or emergencies.

- Ensure proper clearance for electrical panels to prevent code violations and fire risks.

- Reduce the risk of structural failures caused by poorly coordinated MEP layouts interfering with load-bearing elements.

2. Sustainability gains through reduced material waste

Construction waste accounts for nearly 30% of project costs, often due to poor planning and last-minute modifications. Automated MEP clash detection in BIM helps reduce waste by:

- Preventing over-ordering of materials caused by last-minute design changes.

- Enabling prefabrication of MEP components, reducing on-site material cutting and waste.

- Optimizing energy-efficient layouts, ensuring better HVAC airflow and minimizing energy consumption.

Enhance Coordination & Reduce Rework

Detect and resolve MEP clashes before they impact your timeline.

3. Higher quality assurance for long-term performance

An MEP system that works seamlessly within a building improves operational efficiency and reduces maintenance costs. Clash detection ensures:

- Proper spacing for HVAC ducts, improving air circulation and indoor air quality.

- Accurate alignment of plumbing and electrical systems, reducing future repair needs.

- Elimination of design conflicts, preventing issues that could shorten the building’s lifespan.

How the MEP clash detection process works

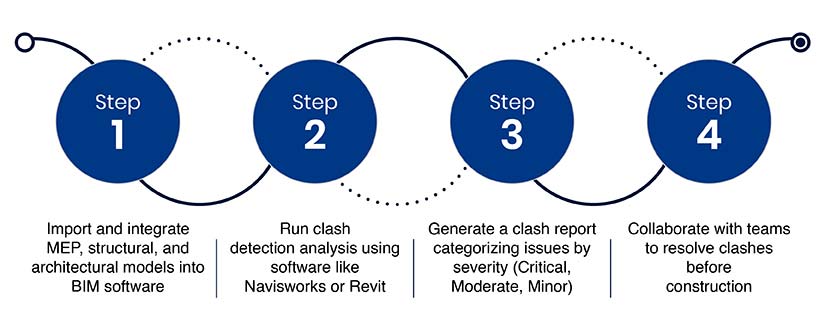

A structured approach to clash detection ensures efficiency, cost control, and seamless execution. The process involves several key steps:

1. Model integration – Aligning different disciplines

Before clash detection can begin, MEP, structural, and architectural models must be integrated into a single federated BIM model. This allows the design team to assess how various systems interact within the structure. Tools like Revit and Navisworks facilitate this integration, ensuring that different disciplines are working from a common, coordinated dataset.

2. Running clash tests – Identifying conflicts

Once the models are integrated, clash detection software performs an automated scan to flag conflicts. These tests analyze spatial relationships, identify overlaps, and highlight elements that do not adhere to pre-defined tolerances. Navisworks’ clash detection tool, for example, categorizes issues into hard, soft, and workflow clashes, making it easier to prioritize resolutions.

3. Clash reports & prioritization – Addressing the most critical issues first

After completing the clash test, the system generates a detailed clash report outlining all detected conflicts, which are then prioritized based on severity. Critical clashes are major obstacles that must be resolved immediately, such as a duct blocking an emergency exit or a fire sprinkler conflicting with a ceiling beam. Moderate clashes require design adjustments but do not pose immediate risks—for example, insufficient clearance around an electrical panel may necessitate a minor layout modification. Minor clashes involve minor discrepancies, like two pipes being slightly closer than ideal. While these do not halt construction, they may impact long-term maintenance and functionality.

4. Resolution & coordination – Fixing clashes digitally

Once conflicts are identified, project stakeholders, including BIM managers, MEP engineers and structural designers—collaborate to resolve them before construction begins. Solutions may involve adjusting component placement, rerouting MEP systems or refining structural designs. By resolving clashes at the digital stage, teams avoid costly field modifications.

5. Verification & approval – Ensuring a clash-free model

After conflicts are resolved, a final clash detection test is performed to verify that all major issues have been addressed. A clash-free model allows the project to move forward confidently, with fabrication and installation planned according to accurate, coordinated drawings.

5 Best practices for effective MEP clash detection in BIM

1. Early engagement of all stakeholders

Involving MEP engineers right from the schematic design stage fosters interdisciplinary awareness and collaboration. By engaging mechanical, electrical, and plumbing experts alongside architects and structural teams at project inception, you can address layout conflicts early.

Frequent coordination meetings and shared digital environments help teams resolve potential issues before they become costly on-site surprises.

2. Detailed level of development (LOD)

Accurate clash detection hinges on the level of detail captured in each trade’s model. Aim for LOD 300–400 so that MEP elements have precise dimensions and specified materials.

Standardized naming conventions, consistent file structures, and unified data parameters across disciplines significantly minimize confusion and misalignment in the clash detection process.

3. Regular/Incremental Clash Detection

Rather than waiting until the final design, schedule clash detection runs at key project milestones or after any major design update. This continuous approach uncovers smaller issues early, preventing them from evolving into larger, more expensive problems.

The integration of 4D scheduling data provides a comprehensive view of time-based conflicts and resource allocation.

4. BIM execution plan (BEP)

A clearly documented BEP is essential. Specify who executes clash tests, which tools they use and how often they report findings. Also, define model exchange protocols and revision procedures to keep everyone aligned.

A robust BEP streamlines team responsibilities and ensures consistent model progress tracking.

5. Quality control and model audits

Periodic model audits guarantee geometry accuracy and data integrity. During these checks, confirm that as-built changes and design modifications are promptly updated.

Thorough quality control keeps the MEP model aligned with real-world conditions, reducing errors and ensuring a smooth clash resolution process.

Conclusion

For contractors, MEP engineers, BIM managers, and project owners, clash detection is more than just a cost-saving measure—it is a strategic necessity. By resolving conflicts before construction begins, teams can reduce reworks, minimize change orders, and keep projects on track.

The future of clash detection in BIM is evolving with AI-driven predictive modeling, digital twins, and real-time cloud collaboration. These technologies will further enhance efficiency by automating clash resolution, optimizing trade coordination and enabling seamless project execution.

In an industry where delays and cost overruns can mean the difference between profit and loss, adopting MEP clash detection in BIM is no longer an option—it is a requirement for delivering high-quality projects on time and within budget.

Boost Project Accuracy with BIM Clash Detection

Minimize delays and costly modifications with advanced clash resolution.