- Millwork shop drawings turn design ideas into precise fabrication instructions, ensuring quality in custom woodwork projects.

- Detailed drawings optimize material usage, fabrication precision and installation with detailed documentation of all project requirements.

- High quality shop drawings are both a communication tool and QC benchmark for custom woodwork.

Table of Contents

Custom woodwork projects are often so demanding that even the best fabricators struggle to turn design concepts into perfect finished products. Without detailed technical guidance the gap between design and physical reality results in costly mistakes if left unaddressed.

Millwork shop drawings bridge this gap by serving as technical documents that clarify communication between designers, fabricators and installers. These detailed specifications eliminate ambiguity and create a shared understanding of the project requirements, turning abstract design concepts into fabrication instructions that guide every step of the process.

Using detailed shop drawings helps to optimize material usage, streamline production and reduce costly mistakes. This means you deliver better finished products that exceed client expectations and increase profitability.

Challenges in custom woodwork without shop drawings

Not having detailed millwork shop drawings causes problems that affect quality and cost throughout custom woodwork projects. These problems occur at every stage from design interpretation to final installation.

- Design misinterpretation: When fabricators have to interpret design intent from general drawings or verbal descriptions they often end up with misalignments between the design and final product that don’t meet client expectations.

- Dimensional errors: Without precise measurements fabricators produce pieces that don’t fit in the intended location or mate correctly with adjacent components and cause a domino effect of fit issues throughout the project.

- Material waste: Unclear specifications lead to overestimating materials as a precaution or making cutting errors and results in unnecessary waste and extra cost for premium materials.

- Inconsistent detailing: Lack of production documentation causes visible variations in supposedly identical elements especially in projects with multiple matching units where uniformity is key.

- Installation headaches: Installers get no guidance on fastening methods, alignment requirements or field modifications and end up with improvised solutions that compromise structural integrity and aesthetic quality.

- Communication breakdowns: Without shop drawings as a common reference point design changes may not be documented across teams and outdated information is used during fabrication and results in rework.

Improving custom woodwork with accurate millwork shop drawings

Accurate millwork shop drawings give everyone involved in the project a clear understanding and specifications of what’s being built.

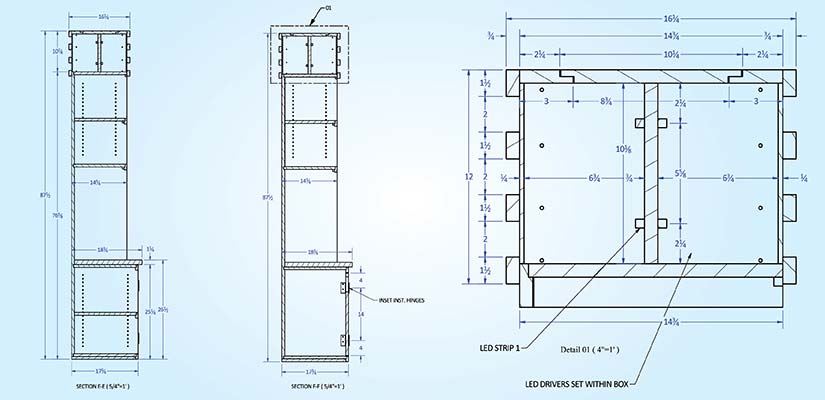

Enhancing dimensional precision using shop drawings

Millwork shop drawings give exact dimensions so there’s no guessing during fabrication. Every component has well defined width, height and depth measurements, including critical tolerances for material and installation.

This eliminates the common problems of overbuild or underbuild while interpreting and deciding based on drafting for custom furniture.

Shop drawings also tie together dimensional relationships between connected components so there’s no mismatch during assembly. When multiple craftsmen are fabricating different parts of a complex millwork project, these drawings ensure all the pieces will fit together.

The drawings maintain dimensional consistency across identical units in multi-part projects, so everything has the same dimensions in the finished installation.

For custom furniture, millwork drawings also capture ergonomic considerations that affect comfort and function. Precise dimensioning of heights, clearances and storage access ensures the finished pieces will perform as intended and look right.

Example:

Consider an office reception desk with book-matched walnut veneer panels and flush-mounted glass display cases. Its curved design is tricky because compound curves create variable angles between joining surfaces that can’t be calculated in the field.

Detailed shop drawings specify clearances (for example, 1/16″) between adjacent panels and allowances (let’s say 1/8″) for the tempered glass inserts. This precise specification ensures grain patterns line up and materials fit together seamlessly.

Ensuring fabrication accuracy in custom woodwork projects

Documentation of fabrication processes through detailed millwork shop drawings creates accountability throughout production. Each step can be verified and tested for quality against the approved drawings, preventing issues during fabrication.

Key fabrication accuracy benefits of millwork shop drawings include:

- Joint type specification: Detailed documentation of what type of joint to use (dovetail, mortise and tenon, miter, mechanical fastening) for each connection point to ensure structural integrity and finish.

- Joinery dimensioning: Precise measurements for joint depths, widths and angles so components fit together without gaps for seamless connections.

- Hardware placement precision: Exact coordinates for hinges, pulls, slides and specialty mechanisms to ensure proper operation and alignment.

- Hardware clearance planning: Detailed allowances for door swings, drawer extension and moving components to prevent interference with adjacent elements or building features.

- Component assembly sequence: Step by step instructions for the logical assembly sequence to prevent errors where later components might block access to earlier connection points.

- Subassembly integration strategy: Clear instructions for how separate fabricated elements come together in the final installation to ensure alignment of seams, hardware and functional features.

For shops with CNC machinery, properly prepared millwork shop drawings are directly translated into machine instructions. This minimizes human error in the fabrication process and maximizes the precision of the machine. The drawings specify tool paths, cutting depths and other machining parameters.

Example:

When building a series of commercial retail display fixtures with intricate geometric patterns, G-code compatible shop drawings are imported into the shop’s CNC router. This eliminates manual programming errors and ensures all units have identical logo recesses and precise shelf pin holes across the production run.

Eliminate field errors with millwork shop drawings from our team

Faster approvals with industry standard millwork documentation

Optimizing material planning through shop drawings

Millwork shop drawings allow for precise material takeoff for woodwork that specifies the exact wood type, quantity and dimension for each component. Material specifications in shop drawings help with cost estimation and procurement planning. Fabricators can identify long lead items to order early and stage material to match production schedule.

Material selection has a big impact on the visual quality of custom woodwork. Shop drawings also document material grade and appearance requirements for visible surfaces. By specifying grain patterns, color matching parameters and acceptable natural variations, drawings ensure visual consistency throughout the finished project.

| Material planning element | No shop drawings | With detailed shop drawings |

|---|---|---|

| Material ordering | Estimate based on general dimensions | Precise quantities based on detailed takeoffs |

| Yield optimization | Ad-hoc cutting decisions | Planned layouts to maximize material usage |

| Species selection | General specifications | Documented requirements for each component |

| Grain matching | Field decisions during fabrication | Predetermined matching patterns |

| Specialty materials | Late identification causing delays | Early specification to enable timely procurement |

Shop drawings created with CAD allow fabrication teams to generate virtual layouts that optimize the placement of components on raw material boards. This digital planning is especially useful for complex assemblies like cabinets where precise quantity takeoffs, board level nesting and layered material specifications are critical.

By simulating cut patterns and calculating material consumption ahead of time, teams reduce offcuts, control costs and improve overall fabrication efficiency.

Macros driven quantity takeoffs for cabinet manufacturer

A US-based high-end kitchen cabinet manufacturer had fragmented drawing processes, skills gaps in cost estimation and long manual quantity takeoffs that were slowing down bidding and reducing bid accuracy. They needed faster, more reliable quantity calculations to increase bid efficiency and win rates.

HitechDigital’s team used 2020 Design and custom Excel macros to turn architectural plans into accurate cabinet quantities. Collaborative sessions ensured error-free layouts and automated extraction of materials, hardware and board specifications made bid preparation a breeze.

The final deliverables led to:

- Higher bid-to-win ratio

- Faster material takeoff calculations

- Operational scalability

Minimizing installation errors with clear drawings

Cabinet shop drawings have explicit fastening and anchoring instructions to ensure secure installations. These specs list the right hardware, quantities and locations while detailing how to connect to surrounding structures.

Field conditions are also considered in shop drawings. Measurements account for wall irregularities, floor slope and other site-specific challenges that can affect installation. This way, fabricators can build in the adjustments rather than having installers make field modifications that compromise quality. Overlooking these details is actually one of the most common millwork drafting mistakes.

Preventing misalignment and refitting is one of the biggest benefits of millwork shop drawings. By documenting spatial relationships and clearance requirements, drawings ensure all components fit the building structure and also their adjacent millwork elements.

Example:

Consider a hospital pharmacy with custom medication dispensing cabinets. Without millwork shop drawings, installers would show up with fully built cabinets only to find recessed sprinkler heads that can’t be moved. They would have to make on-site modifications with hand tools and compromise cabinet integrity and finish quality.

With shop drawings, the cabinets would be prefabricated with exact notches (example: 3¼” × 2½” × 1⅜” deep) in the right locations so they could fit around the sprinklers and meet the project schedule.

Improving coordination using detailed shop drawings

Detailed architectural millwork drawings allow for early review and approval before fabrication begins. This collaborative process lets architects, designers, fabricators and clients identify and resolve issues while changes are still cheap.

Shop drawings are the central reference throughout the project lifecycle, one source of truth that everyone can reference. This eliminates the problems that come from teams working off different information or old drawings. When design changes happen, the shop drawing revision process ensures everyone gets the updated information.

The coordination benefits of custom millwork detailing through shop drawings also include regulatory compliance. By documenting how millwork elements meet building codes, accessibility requirements and other regulations, drawings provide verification that can be shared with inspectors and approval authorities.

Details that define high-quality millwork shop drawings

Millwork drawing accuracy depends on elements that set shop drawings apart from general construction documents. These technical drawings must provide all the information needed for fabrication, assembly and installation while staying organized so they are easy to use throughout the project lifecycle.

Professional millwork drafting services ensure that the following are always incorporated in the shop drawings:

Title block information

Professional millwork shop drawings have complete title blocks with project metadata including client information, project name, drawing number and revision history. This keeps all stakeholders on the same page and prevents work based on outdated versions.

Multiple view representation

Plan views, elevations, sections and detail callouts show every millwork element. This gives fabricators a complete picture of the component from multiple angles, so they understand both visible and hidden construction requirements.

Accurate and detailed dimensions

Overall dimensions, component level measurements and critical tolerances prevent errors from adding up. Properly structured dimension chains establish dimensional hierarchies, so components fit together without field modifications.

Material specifications

Material requirements go beyond just wood species to include grade standards, grain direction and finish specifications. This ensures aesthetic consistency on visible surfaces and specifies the right material for structural components.

Joinery documentation

Clear illustrations of how components connect provide fabricators with exact instructions for joints, fasteners and adhesives. This documentation ensures preservation of design intent throughout the fabrication process.

Hardware coordination

Hardware schedules provide exact placement coordinates and part numbers for all functional components. This prevents improper installation that could affect operation or longevity of the millwork.

Installation guidelines

Field verification callouts and adjustment procedures address site conditions that affect millwork placement. These guidelines provide solutions for site variations without compromising quality during installation.

Drawing standardization

Consistent labeling conventions, layer organization and annotation styles make millwork shop drawings easy to use across project teams. This standardization keeps stakeholders on the same page and reduces interpretation errors that can affect fabrication quality.

Meeting quality standards through millwork shop drawings

Millwork shop drawings are the key to meeting regulatory requirements and quality standards on custom woodwork projects. By putting code requirements into fabrication documents, these drawings prevent compliance issues from popping up during installation or inspection phases.

This proactive approach covers accessibility standards, fire codes and structural requirements before production even begins.

Architectural intent is preserved through detailed shop drawings. By documenting design concepts alongside technical specs, drawings ensure fabricators understand not just the dimensional requirements but the aesthetic goals behind those specs.

The following table highlights the key quality aspects that millwork shop drawings help standardize:

| Quality standard aspect | Role of millwork shop drawings |

|---|---|

| Regulatory compliance | Documents how millwork meets ADA, fire code, and structural requirements |

| Architectural intent | Preserves design vision through detailed specifications |

| Material quality | Establishes grade standards and appearance criteria |

| Craftsmanship | Specifies joinery methods and finish expectations |

| Consistency | Ensures uniformity across repeated elements |

| Performance | Documents hardware functionality and durability requirements |

Quality control processes rely heavily on shop drawings during inspection phases. Fabrication teams use drawings as references during internal quality checks, while third-party inspectors and clients refer to the same drawings during acceptance reviews. This common reference point creates an objective criteria for evaluating work quality and removes subjective judgment from the approval process.

Conclusion

Millwork shop drawings are the backbone of high-end custom woodwork projects. By providing documentation of design intent, technical specs and fabrication requirements these drawings create a common language among all project stakeholders. This eliminates the interpretation gaps that lead to quality compromises and costly mistakes.

For millwork professionals who want to deliver superior custom woodwork, shop drawings are an essential quality control tool. As projects get more complex these detailed technical documents are crucial to maintaining quality and managing production costs.

Get custom cabinetry and woodwork drafted for fabrication ease

Shop drawings tailored to your brand and project goals