- Millwork drafting services translate design concepts into technical drawings, ensuring accuracy and efficiency in fabrication.

- Outsourcing these services provides expertise, efficiency, accuracy, and cost savings.

- When selecting a provider, consider experience, technical skills, communication, quality assurance, and pricing.

Table of Contents

Choosing the right millwork drafting service provider is crucial for architects, contractors and interior designers because the choice impacts project timelines, budgets and quality. As custom millwork projects become increasingly complex, AEC firms often struggle to find providers who can consistently deliver accurate millwork shop drawings while adhering to project schedules.

Outsourcing millwork drafting to the right provider offers a strategic solution, combining specialized expertise in CAD/CAM software with deep understanding of woodworking principles and industry standards. These providers can translate complex design concepts into detailed shop drawings that guide precise fabrication and installation, while ensuring compliance with AWI and AWMAC standards.

To select the best provider, evaluate their experience with similar projects, assess their technical expertise in using CAD/CAM software, and review their portfolio to gauge the quality of their work. Look for providers who prioritize communication, have a strong quality control process, and adhere to deadlines.

By carefully evaluating experience, technical capabilities, quality assurance processes, and communication protocols, you can find a millwork drafting service provider who will enhance your project efficiency and reduce costly errors.

Understanding millwork drafting services

Millwork drafting services translate architectural designs into precise technical drawings used by fabricators to manufacture custom woodwork. These drawings serve as the blueprint for creating various millwork elements, including cabinetry, doors, windows, staircases, wall paneling, moldings and custom furniture pieces.

Millwork drawings come in different types, each serving a distinct role throughout your project. Design drawings, typically developed during the schematic design phase, serve as conceptual tools primarily for client presentations and initial planning.

They capture the essence of your design intent, showcasing the overall layout, style and arrangement of millwork elements.

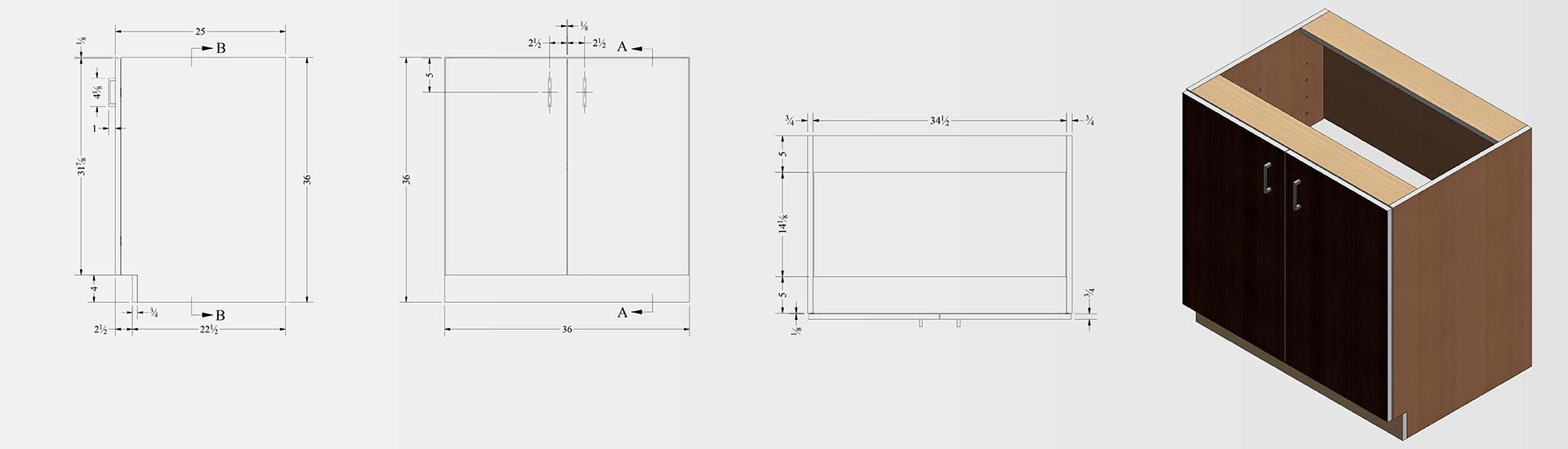

Shop drawings are your detailed and technically precise blueprints, specifically created for fabrication and installation. Shop drawings include everything from precise dimensions and material specifications to joinery details and hardware schedules. In essence, they provide all the information necessary for accurate manufacturing and assembly.

Within shop drawings, you’ll find further classifications. Submittals are used for review and approval by architects and engineers, while fabrication drawings provide specific instructions for the shop floor. Sometimes, you’ll also encounter separate installation drawings, which outline placement and assembly instructions for your on-site crews.

Importance of millwork drafting services

Millwork drafting services facilitate clear communication among designers, architects, contractors, and fabricators, thereby minimizing errors and rework.

Accurate shop drawings promote efficient production timelines and reduce material waste. They ensure the final product aligns with the design intent and meets the required quality standards. These services also improve cost control by enabling accurate material takeoffs and minimizing on-site adjustments.

For complex projects, the drafting process generates 3D models and visualizations. These enhance communication and aid in clash detection, which prevents costly issues during construction. The precision and detail of professional millwork drafting services significantly contribute to project efficiency, cost-effectiveness, and the overall quality of the finished product.

Benefits of outsourcing millwork shop drawings

Millwork quality depends on precise details, achievable through expertise and resources often challenging to maintain in-house. This is where the outsourcing millwork shop drawing services give you an edge.

1. Expertise and specialization

When you outsource millwork design and drafting, you gain access to a specialized team proficient in industry-standard millwork drafting tools such as AutoCAD, Microvellum, and 2020 Design. These experts understand joinery, wood species, hardware and finishing techniques. They ensure adherence to AWI and AWMAC quality standards.

This expertise translates into detailed, accurate shop drawings that clearly communicate design intent, minimizing ambiguity during fabrication. The drafters offer valuable design assistance, suggesting optimal material usage and construction methods. Their practical woodworking knowledge facilitates a collaborative approach.

This leads to design enhancements and value engineering opportunities that less-experienced in-house teams might miss.

2. Increased efficiency

Outsourcing your drafting work streamlines your design process by freeing up internal resources, allowing project managers, architects, and designers to focus on their core competencies rather than getting bogged down in drafting tasks. Dedicated drafting teams expedite turnaround times and promptly deliver shop drawings to keep your project on schedule.

This increased efficiency minimizes project delays and allows for quicker fabrication and installation, which are crucial for meeting deadlines and avoiding costly penalties. A streamlined workflow facilitates better communication and coordination between stakeholders, resulting in smoother project execution.

3. Improved accuracy

Accurate shop drawings are essential for minimizing costly rework. Errors in dimensions, joinery details, or material specifications lead to fabrication mistakes that require on-site modifications or complete remakes. Outsourcing to experienced millwork drafters reduces the risk of such errors.

Their expertise ensures precise shop drawings that translate directly into accurate fabrication. This precision minimizes material waste, reduces labor costs, and prevents project delays. Accurate drawings also facilitate seamless installation as components fit together as intended, ensuring a high-quality finished product.

4. Cost-effectiveness

When you outsource millwork drafting, you eliminate the need for in-house drafting personnel. This directly reduces overhead costs associated with salaries, benefits and software licenses. In addition, you gain increased efficiency and minimize rework, which translates to lower material and labor costs.

While the initial investment in outsourcing might appear similar to in-house drafting, the long-term financial benefits are significant. Expect to see savings from reduced errors, faster project completion, and optimized resource allocation. This frees up resources for other critical project areas, ultimately maximizing the overall value of your project.

Need precise shop drawings for your millwork project?

Ensure accurate fabrication with our detailed shop drawings.

Key selection criteria for millwork drafting service providers

Selecting the right millwork drafting service provider significantly impacts the success of a project. Here are a few criteria you should look for:

1. Experience and portfolio

When selecting a millwork drafting provider, prioritize those with a proven track record. Examine their portfolios, focusing on the complexity and style of their past projects. Look for providers who have successfully completed projects similar in scope and style to yours. This demonstrates their understanding of the unique challenges your project may present.

Beyond general millwork experience, seek out specialized expertise. If your project includes complex curved elements or intricate historical replication, ensure your provider has the necessary skills. Review examples of their shop drawings and installation documents to evaluate their technical proficiency.

Client testimonials provide valuable information about a provider’s professionalism, communication style, and ability to deliver on time. Consider their responsiveness to design revisions and their problem-solving skills. Choose providers with a history of successful projects and satisfied clients.

2. Technical skills

Millwork drafters need proficiency in industry-standard CAD software. Look for drafters competent in CAD, including parametric modeling and families. Beyond software, evaluate their understanding of industry standards, such as those from the Architectural Woodwork Institute (AWI).

These standards define quality for materials, construction and installation, which directly impacts shop drawings. and fabrication. A service provider must understand these standards and incorporate them into their drafting. This includes proper dimensioning, tolerances and material callouts that conform to AWI guidelines.

Also, assess their knowledge of drawing conventions and best practices for millwork. This includes joinery techniques, hardware schedules and detailed sections that clearly communicate the design intent. Ensure they can create comprehensive shop drawings ready for fabrication and installation to minimize errors and rework on-site.

3. Communication and collaboration

Misunderstandings or delays during the drafting stage can lead to costly fabrication errors and project setbacks. A skilled millwork drafting service provider recognizes this and prioritizes establishing strong communication channels from the beginning.

When evaluating potential providers, examine their communication protocols closely. Do they assign dedicated project managers? Do they provide real-time progress updates through project management software or client portals? Ask about their methods for handling RFIs and design revisions. A streamlined process for incorporating feedback is essential.

Effective collaboration also depends on the provider’s ability to understand and interpret the design intent. This requires technical expertise and a strong commitment to collaborative problem-solving. Seek providers who demonstrate a genuine interest in understanding your project vision and who actively engage in discussions to ensure alignment.

4. Quality assurance processes

Quality assurance (QA) in millwork drafting is crucial to minimizing costly errors and delays. Choose providers with multistage QA checks. This should include internal reviews and opportunities for client feedback and revisions at key milestones.

Specifically, scrutinize the provider’s procedures for the following:

| Aspect | What to Look For | How It Helps |

|---|---|---|

| Material Verification | Verify materials meet project specs and industry standards. | Prevents compatibility issues. |

| Dimensional Accuracy | Drawings must account for tolerances. Verify CAD use and adherence to standards. | Prevents fabrication and installation errors. |

| Compliance Checks | Shop drawings must comply with building codes and regulations. | Ensures project meets legal requirements. |

| Constructability Analysis | Assess feasibility of fabrication and installation based on drawings. | Identifies potential challenges early on. |

| Documentation and Revision Control | Maintain a clear system for managing drawing revisions and changes. | Ensures effective communication and traceability throughout the project. |

A provider’s commitment to robust QA demonstrates a dedication to delivering accurate, complete, and constructible millwork drawings.

Elevate your space with bespoke millwork design solutions.

Let us craft custom millwork designs for you that inspire.

5. Pricing and value

When choosing a millwork drafting service, examine pricing structures both for transparency and project scope compatibility. Some providers charge per drawing, while others use hourly rates or fixed bids for the whole project. For projects with changing needs, a time and materials contract with clear spending limits can help you control costs while allowing flexibility.

Beyond the initial cost, consider the total value: a lower price might not result in lower overall costs if the work requires significant corrections due to errors or misunderstandings. Assess the provider’s millwork drafting techniques and standards in specialized millwork drafting tools such as Inventor, Microvellum, 2020 Design, and Cabinet Vision.

For example, a provider skilled in parametric modeling can make design changes easily and create accurate shop drawings, saving time and money in the long run. Strong quality assurance and clear communication reduce errors, prevent costly reworks, and keep your project on track.

Millwork outsourcing provides joinery manufacturer with cost advantage and flexibility

Client: A UK-based bespoke joinery manufacturer with 30 years of experience, specializing in high-end residential markets, producing quality windows, doors, kitchens, bathrooms, desks, and cabinetry.

Challenge: The client faced fluctuating work volumes, skill gaps leading to missed deadlines, a diverse product range requiring varied expertise, and reliance on AutoCAD 3D while the industry standard was AutoCAD 2D.

Solution: We assembled a specialized, scalable team with diverse skill sets, proficient in AutoCAD. We delivered detailed 2D shop drawings, Bills of Materials, and installation guides within stipulated timelines, enhancing flexibility and access to high-end skills.

Read full Case Study »Evaluating millwork drafting services for architectural projects

To integrate millwork designs with the overall architectural vision, millwork drafting services prioritize close collaboration with architects and stakeholders, ensuring a unified approach where millwork complements every facet of the project.

When you outsource millwork drafting for architectural projects, the drafters should ensure that millwork elements not only look good but also meet the project’s functional requirements. Here’s how this can be achieved:

- Prioritize functionality: Ensure all elements meet the project’s functional requirements, such as accessibility, egress, and fire safety, while maintaining aesthetic standards.

- Adhere to codes and standards: Drafters must be familiar with the latest building codes and standards to ensure compliance.

- Collaborate with fabricators: Close collaboration with the millwork fabricator is essential to ensure correct installation and adherence to all functional requirements.

- Consider accessibility: Millwork elements should be designed to be accessible to all users, including those with disabilities.

- Ensure egress: Millwork should not impede egress routes or obstruct fire exits.

- Address fire safety: Millwork materials and designs should comply with fire safety regulations.

Conclusion

Choosing the right millwork drafting service provider is a strategic decision that extends beyond mere cost considerations. The ideal partner combines technical expertise, industry knowledge, and robust quality assurance processes to ensure efficient fabrication and installation. When evaluating providers, focus on their track record with similar projects, their understanding of industry standards, and their ability to communicate effectively throughout the project lifecycle.

Keep in mind that the most valuable provider isn’t necessarily the least expensive—they’re the one who consistently delivers accurate drawings, preventing costly mistakes and delays while maintaining project timelines. By selecting a provider who aligns with these criteria, you invest in your project’s success and your firm’s reputation.

Bring your millwork vision to life with our shop drawings

Streamline your workflow with expert millwork shop drawings.