- Millwork drafting requires a systematic approach with multi-stage quality control and clear documentation to minimize errors and ensure accurate execution.

- It is crucial to avoid common mistakes such as insufficient detailing, neglecting tolerances, and overlooking material properties and industry standards.

- Best practices include using CAD tools, adhering to communication protocols, implementing quality control checkpoints, and selecting appropriate materials and software.

Table of Contents

- Common millwork drafting mistakes

- Avoiding measurement and dimension pitfalls in millwork drafting

- Avoiding ambiguity by documenting essential details

- Ensuring correct material selection during millwork drafting

- Millwork drafting best practices for effective communication

- Quality control checkpoints for millwork detail drawings

- Adhering to drawing standards and code compliance

- Conclusion

Millwork fabricators and designers frequently encounter frustrating roadblocks when projects suffer from dimensioning inconsistencies, vague material specifications and poorly planned hardware clearances. These seemingly minor millwork drafting oversights cascade into major headaches, forcing expensive modifications, pushing deadlines in projects, and creating tension between design teams and fabrication shops as product quality suffers.

The solution lies in adopting a methodical approach built on proven practices. By implementing multi-stage quality control reviews, standardized drawing formats, and meticulous documentation of materials and assembly methods, millwork shop drawing services design their workflows to catch issues early.

This systematic approach emphasizes critical steps in millwork drafting like verifying field measurements against architectural drawings, incorporating proper expansion tolerances, and detailing joint specifications. Modern CAD tools and advanced millwork drafting techniques further enhance precision and efficiency.

The payoff from avoiding common millwork drafting mistakes is significant. Projects flow more smoothly, with fewer shop drawing errors and clearer technical requirements that leave little room for misinterpretation. Design intent translates seamlessly to fabrication, creating millwork drawings that uphold professional standards while meeting or exceeding client expectations. This improved millwork drafting workflow strengthens relationships between stakeholders and helps ensure the final product matches the original vision.

Common millwork drafting mistakes

Even experienced millwork drafters fall prey to common pitfalls that compromise the accuracy and clarity of their drawings. Here are some crucial millwork drafting mistakes to avoid:

Insufficient detailing: Insufficient detail leads to ambiguity and misinterpretations during fabrication. Complex joinery, intricate profiles, and unique hardware require comprehensive depictions, often necessitating enlarged views, sections, and detailed sub-drawings.

Inconsistent dimensioning: Maintaining consistency and uniformity in dimensioning—whether it’s fractional or decimal, inches or millimeters—is crucial for clarity. A mixed system introduces confusion and increases the risk of errors during production.

Lack of coordination between designers and engineers: Poor communication between design and engineering teams often results in conflicts between aesthetic vision and structural requirements. Establish clear channels for regular collaboration and information sharing to ensure designs are both visually appealing and technically sound.

Overlooking material specifications and tolerances: Inadequate attention to material properties and acceptable variations can lead to installation problems. Every material has unique characteristics that must be accounted for in the drafting process with appropriate specifications and tolerance allowances.

Inaccurate measurements and scaling issues: Precision in measurements is fundamental to successful millwork. Errors in scale or dimensions can render an entire project unusable. Always double-check measurements and verify that drawings maintain consistent scale throughout all views and details.

Not adhering to industry standards and codes: Failing to follow established standards from organizations like the Architectural Woodwork Institute (AWI) creates inconsistency and quality issues. These standards provide essential guidelines for material selection, construction techniques, and finishing that ensure quality and compliance.

Disregarding installation considerations: Drawings that focus solely on fabrication without considering the installation process create on-site complications. Provide clear instructions on sequencing, attachment methods, and any necessary site modifications for efficient installation.

Being mindful of these potential pitfalls helps expert drafters minimize woodworking drafting errors and ensure successful project outcomes.

Ensure precision with custom millwork shop drawings for accuracy

Transform designs into flawless millwork with our expert shop drawings

Avoiding measurement and dimension pitfalls in millwork drafting

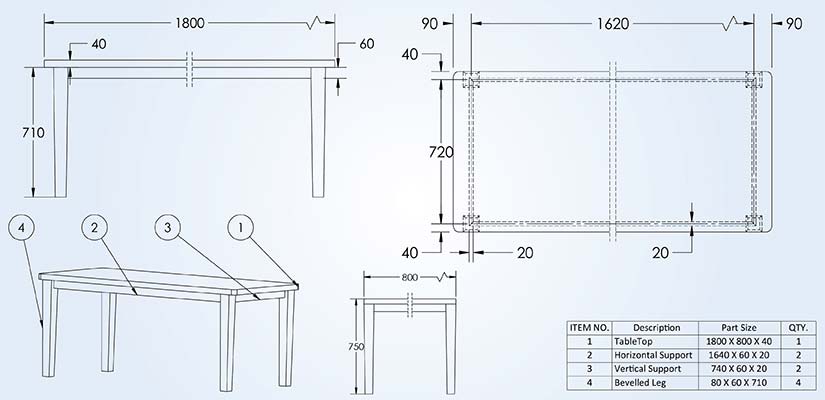

In millwork drafting, even minor dimensional errors cascade into major problems during fabrication and installation. For instance, cabinets that don’t align with the wall or door frames that are slightly too small – these discrepancies can necessitate costly rework and compromise the entire project.

Professional millwork detail drawings demand rigorous adherence to measurement protocols, particularly when dealing with complex architectural features. This might involve laser measuring tools, photogrammetry, or even 3D scanning to capture the precise dimensions of existing structures. Employing these techniques minimizes the risk of inaccuracies creeping into the drawings.

Leveraging CAD to create detailed virtual mock-up models early in the process also reduces alignment issues during installation.

The following are some tips to avoid measurement and dimensional mistakes:

- Always verify field measurements against architectural drawings

- Include clear dimensioning hierarchies that prioritize critical measurements

- Document material thickness variations and account for them in assembly clearances

- Maintain consistent unit notation throughout drawings

- Consider expansion and contraction tolerances in material specifications and joinery details

For enhanced accuracy, consider using relative dimensioning. This technique involves measuring from the actual framework rather than relying solely on overall dimensions. This minimizes the impact of cumulative custom millwork design errors and ensures a more precise fit.

Avoiding ambiguity by documenting essential details

Thorough documentation of essential details bridges the gap between design intent and flawless execution. Millwork drafters must capture vital information about materials, finishes, hardware specifications and assembly requirements to guarantee successful project execution.

Here are some details that must be incorporated into the drawings:

| Detail Category | Documentation Requirements | Common Oversights | Best Practices |

|---|---|---|---|

| Materials | Species, grade, moisture content | Grain direction | Include material certifications |

| Hardware | Brand, model, finish type | Missing clearance specs | Document load ratings |

| Finishes | Sheen level, coating type | Incomplete prep steps | Note application methods |

| Joints/Fasteners | Connection types, spacing | Unclear screw patterns | Specify exact locations |

Beyond basic specifications, successful documentation requires annotating vital interfaces between millwork components and adjacent materials, while clearly indicating installation sequences that may affect other trades.

Drafters should implement standardized notation systems and maintain consistent detail references across drawing sets. Employ a clear system for referencing details, such as numbered callouts that correspond to enlarged views or sections. This allows for easy navigation and minimizes the risk of misinterpretations.

Ensuring correct material selection during millwork drafting

Success in millwork drafting relies heavily on understanding material properties and their applications. When selecting materials, consider factors such as dimensional stability, moisture resistance, structural integrity, and aesthetic requirements.

Material selection also impacts long-term durability and maintenance, making accurate documentation essential. The Architectural Woodwork Institute (AWI) provides detailed quality standards that guide material selection for different millwork applications. These standards specify acceptable species, grades and moisture content for various components.

Professional drafters must also be aware of both traditional and contemporary material options, including engineered products. The following are some major considerations when selecting materials for millwork:

- Hardwood variations: Account for natural variations in hardwood species, such as grain patterns and color inconsistencies. Consider how these variations affect the final appearance of the millwork.

- Dimensional changes: Wood expands and contracts with changes in humidity and temperature. Choose materials and joinery techniques that accommodate these movements to prevent warping, cracking, or joint failures.

- Sheet goods and composites: When using sheet goods like plywood or MDF, specify appropriate edge treatments and joinery methods to ensure durability and a clean, finished look.

- Veneer compatibility: If using veneers, consider the thickness and compatibility with the substrate to prevent delamination or cracking.

- Cost vs. performance: Balance material cost with performance requirements. While exotic hardwoods may offer superior aesthetics, they may not be necessary or cost-effective for all applications.

Bridge design and manufacturing with detailed millwork plans

Elevate project accuracy with professional millwork detailing

Millwork drafting best practices for effective communication

Achieving precision in millwork necessitates clear and consistent communication among all stakeholders. Prioritize the following best practices to ensure successful project execution:

Standardized communication protocols

Implement a structured system for information exchange. This includes:

- Regular project updates: Schedule recurring meetings or utilize project management software to disseminate progress reports, ensuring everyone remains informed.

- Formal submittal reviews: Establish a standardized process for reviewing shop drawings and specifications, incorporating feedback from all parties in a clear and trackable manner.

- Design change documentation: Maintain a detailed log of all design revisions, clearly outlining the rationale, responsible parties and associated impacts.

Leveraging technology

Modern technology offers powerful tools for enhancing communication in millwork drafting. These include:

- Cloud-based platforms: Utilize cloud-based platforms for sharing drawings and collaborating in real-time, ensuring everyone has access to the latest versions.

- Version control software: Implement systems that track document revisions, ensuring everyone is working with the most up-to-date information.

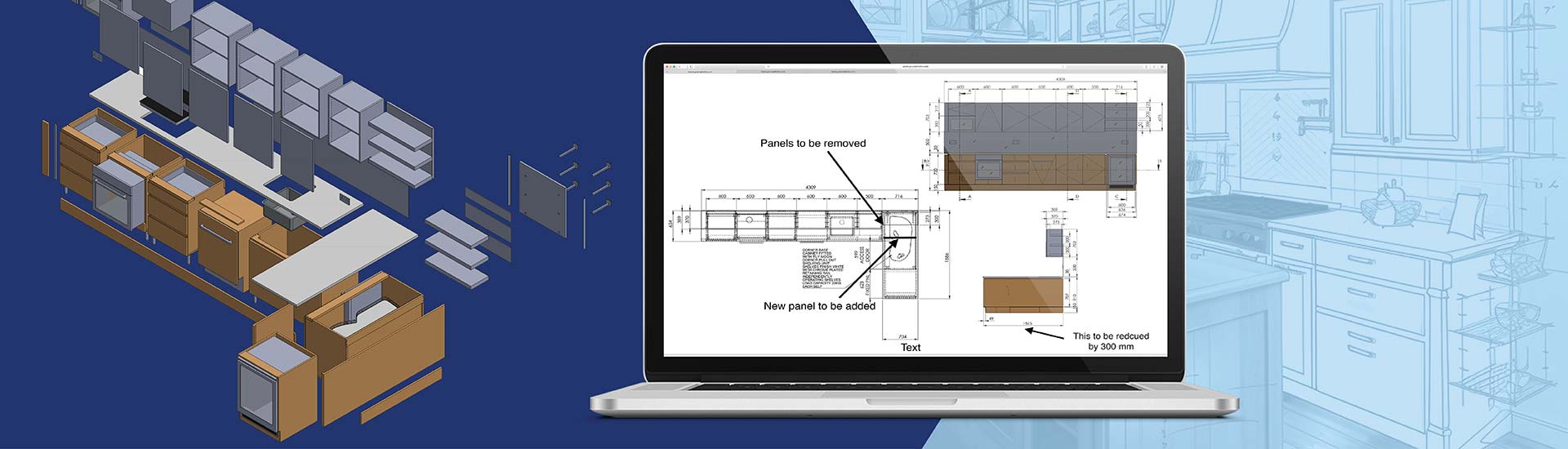

- Visual communication tools: Use visual communication tools, such as 3D models, renderings, and virtual prototypes, to enhance understanding and facilitate discussions about design details.

Proactive conflict resolution

Encourage open dialog and promptly address potential conflicts. This can be achieved through:

- Regular coordination meetings: Facilitate recurring meetings with key stakeholders to discuss technical challenges, clarify design intent and resolve discrepancies before they escalate.

- Constructive feedback mechanisms: Establish clear channels for providing and receiving feedback, ensuring all concerns are addressed in a timely and professional manner.

By adhering to these communication best practices, millwork drafters can minimize errors, prevent costly rework, and ensure project success through collaborative and transparent information exchange.

Enhanced Quantity Takeoffs for Cabinet Manufacturer

A USA-based furniture manufacturer specializing in high-end, frameless kitchen cabinets sought to improve their bid-to-win ratio. The client required efficient preparation of kitchen layout drawings and accurate quantity take-offs from architectural plans to streamline their bidding process.

HitechDigital assembled a team of furniture experts and CAD specialists to analyze architectural floor plans and extract essential details such as cabinet dimensions and 3D locations. Utilizing the inbuilt library of 2020 Design software, the team customized kitchen cabinet models to calculate precise quantities. They employed custom macros and Excel formulas to determine specifications for purchased items, manufactured products, and required raw materials.

The final deliverables led to:

- Increased bid-to-win ratio

- Faster and accurate material takeoffs calculation

- Operational scalability

Quality control checkpoints for millwork detail drawings

Implementing systematic quality control checkpoints throughout the millwork drafting process is crucial for minimizing errors and ensuring the final product meets the highest standards. These checkpoints act as safety nets, catching potential issues before they escalate into costly problems during fabrication or installation.

The following are the key QC checkpoints that professional drafters or millwork shop drawing services must follow:

- Verification of dimensional accuracy and adherence to architectural specifications

- Cross-referencing of material selections against availability and cost constraints

- Assessment of joint details, hardware placement, and assembly sequences for manufacturing feasibility

- Documentation review for compliance with building codes and safety standards

- Final inspection for millwork shop drawing errors against original design intent and client specifications

- Monitoring and assessment of error rate, rework rate, and timeliness of corrections for process optimization

Maintain a clear and comprehensive documentation trail throughout the drafting process. This includes recording all revisions, design changes and approvals. A well-maintained documentation trail facilitates efficient troubleshooting, simplifies revisions, and provides a valuable record of the project’s evolution.

Adhering to drawing standards and code compliance

Industry standards, including AWI specifications and local building codes, establish strict parameters for dimensioning, notation and material specifications that guarantee project compliance. Millwork drawings must adhere to these standards and codes to ensure the final product meets legal requirements and safety regulations.

The following are the major standards and codes and their impact:

| Standard Type | Requirement | Impact |

|---|---|---|

| AWI Quality Standards | Material grades, finishes, tolerances | Guarantees consistency across the industry |

| ADA Guidelines | Clearances, heights, accessibility | Ensures universal access compliance |

| Building Codes | Fire ratings, egress, assemblies | Maintains safety and legal conformity |

Professional drafters and millwork drafting service providers must maintain current knowledge of evolving standards while mastering software platforms that facilitate accurate documentation. It’s also crucial to understand how different codes and standards interact. For example, a fire-rated door assembly may require specific materials, construction methods, and hardware to meet both fire safety and accessibility requirements.

Conclusion

Successful millwork drafting requires careful attention to detail, thorough documentation, and adherence to industry standards. By following established protocols, drafters can minimize errors and project delays and help create a final product that faithfully reflects the design vision.

Implementing rigorous quality control processes, maintaining clear communication and leveraging appropriate technological tools guarantees the delivery of precise, code-compliant millwork documentation that meets both technical requirements and client expectations. The integration of these fundamental practices ultimately determines project success.

Accelerate production with CNC-ready millwork files

Seamlessly transfer designs to manufacturing with our files