- Digital quantity takeoffs reduce errors due to manual measurements when determining accurate quantities of millwork items.

- The accuracy of estimating materials from 3D models eliminates unnecessary waste and provides an accurate estimate involved with all millwork projects.

- Real time collaboration software takes data from digital quantity takeoffs into ERP systems so that project budgets can be developed with complete confidence.

Table of Contents

- Key Challenges in Manual Millwork Material Takeoffs

- 4 Ways Digitalization Helps Millwork Quantity Takeoffs and Material Estimation

- Key tools and technologies for digital takeoffs in millwork

- How to Calculate Accurate Millwork QTOs and Material Estimate

- Best practices for accurate digital QTO and material estimates in millwork

- ROI and strategic benefits for millwork developers

- Conclusion

The competition for millwork fabrication shops to bid accurately is at an all-time high due to their cost contribution to projects (20-30%). Errors made in estimating quantities of materials can lead to a loss of contract or reduced profit margin when bidding.

Estimators use manual processes to create takeoffs which introduce errors in calculations, utilize estimators’ knowledge and experience rather than provide actual data and cannot easily be modified to accommodate design changes. Therefore, millwork project budgeting is subjected to error from the beginning.

Professional millwork takeoff services ensure accurate digital takeoffs and estimates of materials and remove the guesswork associated with estimating quantities of materials by utilizing 3D CAD designs and automation of calculations.

This enable them to bid competitively while maintaining healthy profit margins throughout the project execution.

Key Challenges in Manual Millwork Material Takeoffs

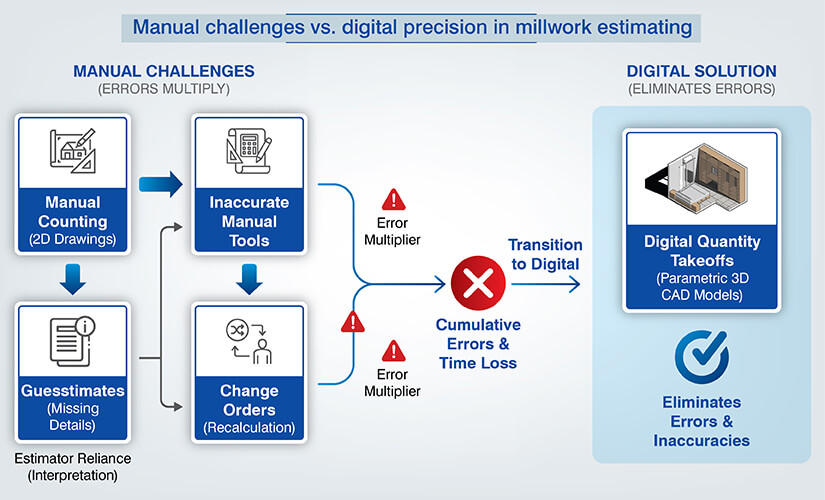

The reliance upon manual counting from 2D drawings and taking-off materials from experience results in errors that are multiplied during execution.

Inaccuracies of manual tools

The rolling scale, highlighter, and calculator all contribute to less-than-precise calculations of material estimating. A small error in a calculation result in deviation from the actual value.

Guesstimates instead of estimates

The missing detail as to the type of wood or lack of conversion scales necessitates that the estimator make an educated guess versus rely on the data to accurately estimate.

Reliant on the estimator

The accuracy of the material takeoff is dependent upon the expertise of the estimator when attempting to interpret the complex 2D drawing.

Change orders

Manual estimates are completely recalculated for change order which again multiplies the errors and time required for completion of the project.

Digital quantity takeoffs and material estimating utilizing parametric 3D CAD models eliminate the potential for these errors.

4 Ways Digitalization Helps Millwork Quantity Takeoffs and Material Estimation

Digital solutions are totally changing the traditional millwork estimation processes – coming up with smarter ways to do things that get rid of guesswork and make things a lot more accurate. Here are the four key reasons why this is such a big deal.

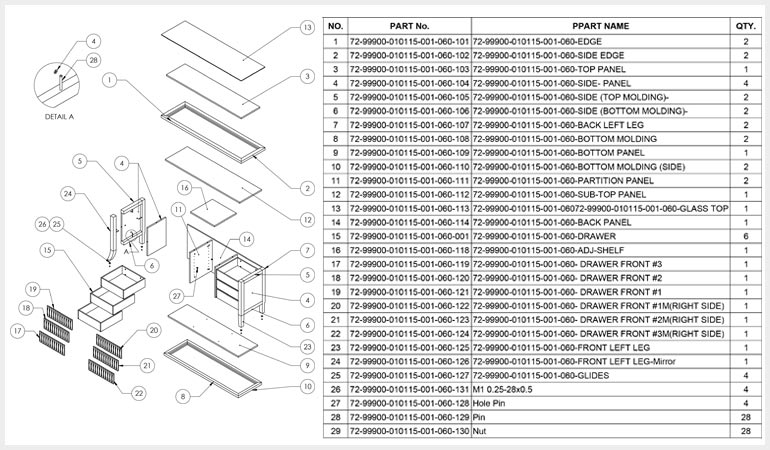

1. Using parametric 3D CAD models and 2D/3D drawings

Now 3D CAD tools have a real edge over manual estimation – they give you super accurate model info and can capture every single detail of the millwork part that’s needed in a building project in a really precise way.

Plus, isometric drawings with exploded views, sections and elevations, manufacturing details and installation instructions let you get the exact number of parts needed – no room for error there.

And one of the big advantages of using CAD platforms is how easy it is to tweak the basic design templates – you can reference any point using spatial coordinates, so you can make changes and keep track of them without messing things up.

The benefits of using CAD-based millwork estimation really boil down to getting a lot more accuracy and being able to visualize super complex components before production even starts.

2. Use of libraries to boost productivity

Millwork design engineers can create their own personal libraries of pre-made, reusable and scalable parametric parts. This makes designing a whole lot faster and estimating more accurate. Most CAD software like AutoCAD or 2020 Design, comes with a whole bunch of built-in blocks, parts and models that you can just copy and paste into your next project, no extra work at all.

Using parts straight from the library means you don’t have to worry about getting the numbers right. They just get pulled in automatically, saving you from all sorts of errors down the line. And if you’re producing a lot of the same type of product like trimmings, moldings, ceiling and flooring, you can grab them from the library and just tweak them a bit to suit your needs.

Macros-driven quantity takeoffs for cabinet manufacturer.

A furniture manufacturer in US was struggling with cost estimation and bid submission as a big skills gap was holding them back. They needed a way to rapidly boost their bid-to-win ratio.

A team of designers at HitechDigital used 2020 Design models to pull quantities from architectural plans, tied them to Excel macros, then defined all the counts for veneer, laminate, MDF and hardware. They automated the whole QTO process – and the reporting too. All in real time.

The final deliverables led to:

- Fast and accurate material take-offs

- Boost to the bid-to-win ratio

- Ability to scale up and take on more businesses

Simplify bidding with reliable millwork quantity data

Win more projects through precise cost forecasting

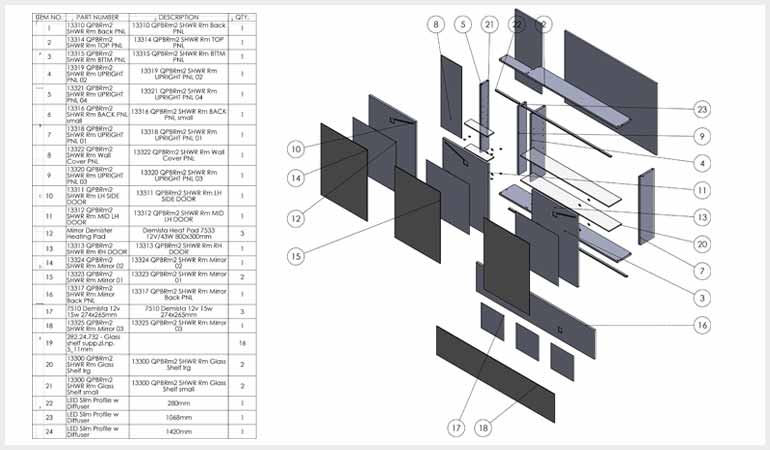

3. Metadata information

Estimators and developers can quickly and easily pull out the useful stuff – like weight, material type, how finished they need to be, volume, length, height, width, and radius – from digital models or drawings for each individual part. The number of parts and how many of each there are gets calculated and a detailed estimate is done up in the right format in no time.

Millwork labor and material analysis really add up when you base it on this solid foundation of metadata, making it possible to compete on price without sacrificing your profit margins.

When you’re working with CAD data, the estimator gets a 360-degree view of the project, one screen at a time, and that helps avoid missing any crucial details. You don’t have to worry that a small door or a linear trim gets overlooked in some big multistorey job.

Doing comprehensive material takeoffs for millwork ensures that nothing slips your mind during the estimation process.

CAD-based digitized workflows help architectural millwork manufacturer save costs

An architectural millwork firm based in Texas, USA, was saving hundreds of dollars a month just by switching to digital workflows for cost estimation. They’re a high-end outfit that specializes in things like trims, wood paneling, and custom cabinetry. For years they were spending a lot of their budget on printing out drawings, redoing designs on a plotter, and paying for all that labor.

The benefits they got from adopting digital workflows were:

- Better day-to-day cost management for every project.

- Super-accurate estimates and bids.

- Huge savings on both time and money.

- More contracts, with a reduced turnaround time.

4. Collaboration and change management

Digital CAD tools like AutoCAD can integrate with external 3rd party tools for quantity and cost calculation and seamless communication across project teams. Manufacturers, contractors and sub-contractors, architects and property owners can use metadata in 3D CAD models and drawings for updated information exchange.

For example, if digital QTOs created from 3D models are connected to your ERP software, you can get detailed insights for cut lists, material availability, purchases and stocks, planned man-hours, costs etc. Based on these insights you can better manage your workforce at shop and installation sites.

3D millwork modeling for budgeting gives you a complete overview of the whole project so you can better plan and schedule your resources.

Key tools and technologies for digital takeoffs in millwork

Millwork professionals now use specialized digital tools to takeoff with precision like never before.

Fabrication-level CAD/CAM systems like Microvellum and Cabinet Vision automatically generate a complete bill of materials from parametric designs. They eliminate manual measurement by embedding material specs, hardware requirements and finish data into component libraries.

Advanced PDF measurement platforms like Bluebeam and Acrobat PDF allow estimators to create custom assembly calculations – a single click on a casework elevation can count the cabinet box, calculate linear feet of toe kick and add square footage of the face frame.

Accuracy is also achieved in quantity takeoff services using Excel spreadsheets and PDF mark-up tools for precise documentation and verification.

Nesting optimization technology determines the most efficient layout of components on standard sheets, replacing generic waste factors with precise material yields and accurate cut lists.

AI recognition tools helps you automatically detect repetitive elements like doors, baseboards and countertops on 2D plans and quantify thousands of feet of trim without manual measurement.

How to Calculate Accurate Millwork QTOs and Material Estimate

Although digitalization has improved QTOs a lot, errors still creep into the final bids and millwork companies lose out on estimated profits.

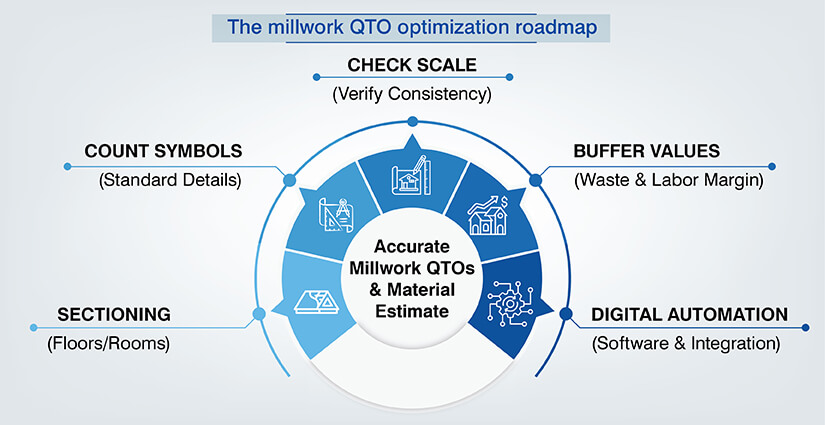

Sectioning of project

To calculate accurate estimates, break down the project into smaller sections and fix the bid values for each part. You can start calculating quantities floor by floor or even room by room for complex projects.

An estimator who is proficient in using automation tools can help you create bids more accurately. Quality millwork takeoff services use this sectioning approach to ensure accuracy across the entire project scope.

Counting the symbols to identify number of components

Logical symbols for instructions in drawings make QTO count easier. But one should look for standard symbols for recurring remarks like wood type, finish etc. in paneling, trims, door etc.

Checking the scale of drawings

Drawing scale is the most important factor for an estimator to ensure consistency across the drawings verified by the project architect / designer. Wrong interpretation of scales will lead you to over-budgeting or under-budgeting the project cost.

Calculating using buffer values

Buffer values like labor for finished carpentry or casework may not be available as metadata count. Estimators should consider such parameters along with material waste on-site while calculating the final estimate value. Experts define this margin to be between 0.5% and 2% based on project complexity.

Millwork companies are using digital blueprints along with takeoff software to partially automate their process. The software allows analyzing blueprints and entering the quantity and measurements in prescribed digital formats. In some cases, the software can integrate with an external bidding or quotation program and automate the entire quotation process.

The Future of Millwork Shop Drawings: Trends and Innovations to Watch

- 3D visualization in CAD enhances conflict detection.

- Macros enable drawing task automation.

- API integration streamlines workflow.

- AR facilitates better visualization and collaboration.

Best practices for accurate digital QTO and material estimates in millwork

In order to get the most out of your digital quantity take-offs and material estimates in millwork, you need to look beyond the functionality of the basic software you are utilizing.

The following best practices will help to guide you through the process:

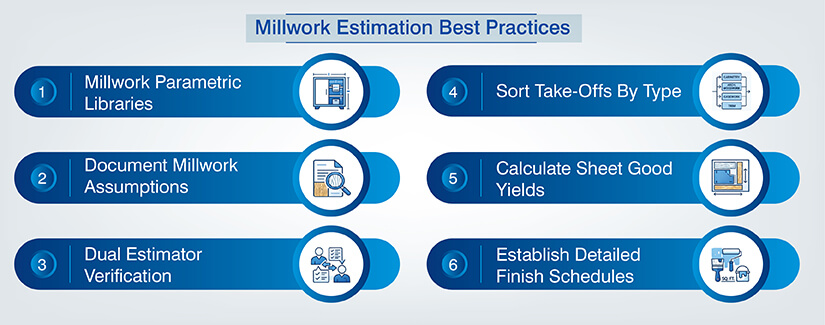

- Develop millwork specific parametric libraries consisting of standard cabinet assemblies, molding profiles and casework components with embedded material specifications and hardware counts.

- Document millwork assumptions such as wood species, grain direction, types of joints, edge banding requirements and finishing specifications.

- Utilize dual verification in which one estimator is responsible for completing the initial millwork quantity take-off and a second verifies the quantities against the shop drawings and material specifications.

- Sort take-offs into millwork type categories (cabinetry, architectural woodwork, casework, and trim), to ensure that accurate material calculations are made for each category of millwork due to their individual requirements.

- Calculate sheet good yields utilizing digital nesting software, taking into account grain matching, veneer orientation and millwork-specific cutting patterns.

- Establish detailed finish schedules breaking down stain, paint and clear coat applications by square footage on each millwork surface.

ROI and strategic benefits for millwork developers

Shops utilizing digital takeoff tools can experience an ROI within months due to several process improvements which impact their bottom line. Estimators are able to reduce labor costs exponentially because the same amount of work previously completed in days or weeks is now being done in hours using digital tools.

Digital tools also enable shops to increase estimating volume without increasing the number of estimators. While cost saving is a strategic benefit of implementing digital takeoff tools, the speed at which shops can respond to Requests For Proposal (RFP) positions them to be the most agile and technologically advanced partner.

Conclusion

The success of a millwork shop really comes down to one thing: are your profits on track with your plans? And the key to that is being able to produce bids on time that are spot on. Digital Quantity Takeoffs (QTOs) and cost-calculating methods give millwork business owners the edge they need to stay on top of things. This is done by using 3D CAD models and drawings, so no more relying on old-fashioned methods.

Outsource to a good professional millwork takeoff services that makes use of digital tools and you’ll be amazed at how much more accurate your estimates can be – and how much less time you’ll need to spend on getting your bid ready for submission.

With digital QTO in place, the human error factor disappears, and it makes collaboration between team members a whole lot easier. And that means you can establish yourself as a with accurate estimates that gets done on time and saves you money.

Bid smarter, fabricate faster with accurate take-offs

Our millwork estimation team delivers clarity & control