- Millwork offers precise, custom wood elements crafted off-site, while carpentry provides on-site structural solutions and finishing touches. Together, they create functional and visually appealing spaces.

- The choice of Millwork vs Carpentry depends on your goals, budget and timeline. Millwork excels in aesthetics and branding, while carpentry ensures practicality and structural integrity.

- Accurate drawings and drafting are essential for ensuring seamless design execution, reducing errors and delivering high-quality results.

Table of Contents

- What is Millwork?

- What is Carpentry?

- Millwork vs Carpentry: Key Differences

- Choosing the Right Option for Your Business

- Integration of Millwork & Carpentry in Projects

- Cost-Benefit Analysis and Return on Investment

- Why Professional Drafting Services Matter for Millwork

- Current Trends and Innovations in Woodworking

- Conclusion

Woodwork plays an essential role in construction and design, shaping how spaces look, feel and function. Whether you’re building an office, renovating a store, or designing a restaurant, incorporating quality wood elements can elevate your business environment. For woodworkers, millwork manufacturers, interior designers, and architects, it’s important to understand the two key approaches to woodworking: millwork and carpentry.

While both crafts involve working with wood, they serve distinct purposes. Millwork involves custom factory-made wood products that add detailed finishes and unique touches to a space. Millwork drafting services help create precise plans and drawings for these custom elements.

On the other hand, carpentry focuses on onsite construction, addressing the structural and foundational aspects of a building.

This blog will break down what millwork and carpentry are, how they differ, and how they can work together to bring your business’s vision to life.

What is Millwork?

Millwork refers to custom wood products crafted in specialized factories or mills. These items are predesigned, fabricated with precision, and then delivered to a construction site for installation. By using advanced tools like CNC machines (Computer Numerical Control) and CAD software (Computer-Aided Design), millwork ensures a high level of accuracy and customization.

Millwork goes beyond decoration—it combines functionality and design to create wood elements that perfectly match the needs and style of a space.

Examples of Millwork in Construction

- Custom Cabinetry: Tailored storage solutions for offices, retail stores, and hospitality venues

- Moldings and Trim: Crown moldings, baseboards, and wainscoting that add character and elegance

- Architectural Details: Coffered ceilings, wall paneling, and unique wood features that elevate aesthetics

- Staircases and Railings: Custom designs that ensure safety while enhancing visual appeal

- Built-In Furniture: Reception desks, shelving units, and seating areas tailored to specific dimensions

Benefits of Millwork

- Precision and Quality: Fabricated in controlled environments, millwork guarantees consistent results and exact measurements.

- Customization: Businesses can create unique designs that aligns with their branding and operational needs.

- Advanced Planning: Detailed Millwork Shop Drawing Services ensure every piece is crafted to fit seamlessly.

Millwork is ideal for businesses that want highly customized, premium wood features to enhance their spaces. It’s especially effective for creating cohesive, polished environments that reflect your brand identity.

What is Carpentry?

Carpentry involves building and assembling wooden structures directly at the construction site. Unlike millwork, which is premanufactured, carpentry focuses on crafting, installing and adjusting wood elements in real time. Carpenters work on everything from structural frameworks to detailed finishing touches, combining functionality with craftsmanship.

Key Types of Carpentry

- Rough Carpentry: This involves constructing the foundational framework of buildings, including walls, floors and roofs.

- Finish Carpentry: Adds finishing elements, such as doors, windows and trim, to make the space functional and visually appealing.

- Trim Carpentry: Specializes in installing decorative features like crown moldings, baseboards and chair rails.

- On-Site Cabinetmaking: While custom cabinetry is typically part of millwork, carpenters often build or adjust cabinets on-site when needed.

Benefits of Carpentry

- On-Site Flexibility: Carpenters adapt to on-site conditions, solving challenges in real time.

- Structural Importance: Carpentry ensures that the building’s framework is solid and meets safety standards.

- Cost-Effective: Carpentry is often more affordable for standard structural or finishing tasks.

For businesses, carpentry is essential for creating the structure and foundational elements of a building while adding practical, functional wood details. Its adaptability on-site makes it a critical component of any construction project.

Millwork vs Carpentry: Key Differences

| Factor | Millwork | Carpentry |

|---|---|---|

| Customization | Tailored to exact specifications for high personalization; ideal for unique, branded elements like custom cabinetry or intricate wood details. | Follows standard designs or blueprints with some on-site adjustments; custom work is possible but less detailed than millwork. |

| Precision and Tools | Uses advanced machinery like CNC machines and CAD software like AutoCAD, Inventor, Microvellum, Cabinet Vision, 2020Design for precise measurements and consistent quality. | Relies on the carpenter’s skill and tools, including power tools and traditional hand tools, for precision. |

| Production Location | Crafted in controlled factory environments, minimizing external influences like weather or site conditions. | Performed on-site, requiring adaptability to environmental factors and on-the-spot problem-solving. |

| Cost Considerations | Typically more expensive due to premium materials, customization, and specialized craftsmanship. | More budget-friendly, focusing on essential structural work and finishing tasks. |

| Materials and Quality | Uses premium materials like high-grade hardwoods and veneers for superior aesthetics and durability. | Utilizes a wider range of materials, including softwoods and engineered wood, based on structural needs and budget. |

The Future of Millwork Shop Drawings: Trends and Innovations to Watch

- 3D visualization in CAD enhances conflict detection.

- Macros enable drawing task automation.

- API integration streamlines workflow.

- AR facilitates better visualization and collaboration.

Choosing the Right Option for Your Business

When deciding between millwork and carpentry services, several factors play a key role in ensuring your project meets both functional and aesthetic goals:

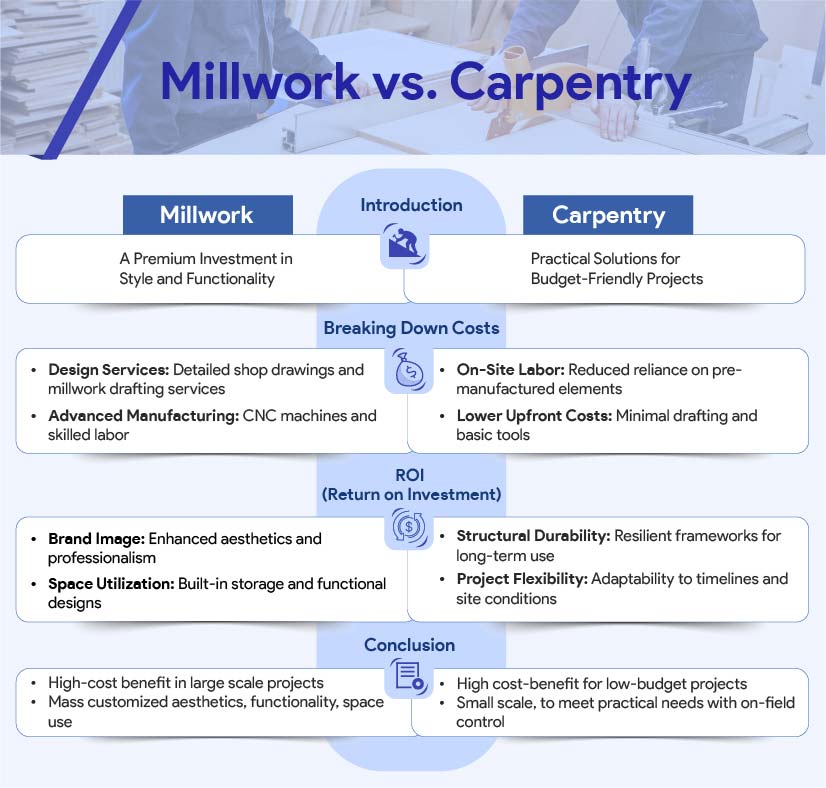

Budget Constraints

- Millwork often comes with a higher price tag due to its custom nature, premium materials, and specialized craftsmanship. If your business needs high-end, customized finishes that reflect your brand identity, millwork may be the right choice.

- Carpentry, on the other hand, is more budget friendly and focuses on structural or standard finishing tasks. It’s a great choice for businesses that prioritize functionality over high customization.

Design Requirements

- If your project requires custom millwork services tailored to your brand and specific space needs, millwork is the ideal solution. Custom cabinetry, intricate moldings, and unique wood features are all hallmarks of millwork.

- If your design is more straightforward and revolves around essential structural elements, carpentry techniques might be sufficient. Carpenters excel at implementing standardized designs, such as framing, doors and windows.

Project Timeline

- Millwork typically involves a longer lead time, as pieces are fabricated off-site and need to be carefully planned and manufactured. For projects that require high precision and customization, be prepared for a longer timeline.

- Carpentry can be more flexible and efficient, especially if the work can be done directly on site. Carpenters can make adjustments as needed, making them a good choice when the project timeline is tight.

Functional Needs

- If your priority is to create a space with distinctive, brand-aligned finishes, millwork in construction offers unparalleled customization to meet these needs.

- If you require a solid, functional framework or need finishing touches that are durable and simple, carpentry is more than adequate for those needs. It’s essential for constructing and assembling foundational elements that ensure safety and longevity.

Integration of Millwork & Carpentry in Projects

Sometimes, a combination of both millwork and carpentry is the best solution. For example, you might use millwork for custom cabinetry or detailed architectural features, while carpenters handle structural framing and installation.

This approach ensures you get the best of both worlds: the intricate, high-end finishes of millwork with the solid, practical framework of carpentry. Some real-life examples include:

- A custom reception desk crafted through millwork may require a carpenter for precise on-site installation.

- Moldings and trim produced off-site as part of millwork are installed by carpenters who ensure they align perfectly with the surrounding elements.

- Custom-built furniture or wood paneling from millwork often depends on carpentry for proper framing and support.

Benefits of Collaboration

Combining millwork and carpentry ensures:

- Design Consistency: Seamless integration of custom wood elements into the building.

- Efficient Execution: Collaborative efforts reduce delays and errors during installation.

- Quality Assurance: Projects benefit from the precision of millwork and the adaptability of carpentry.

Cost-Benefit Analysis and Return on Investment

Why Professional Drafting Services Matter for Millwork

When you’re looking to incorporate custom wood elements into your business space, professional drafting services are invaluable. Expert Millwork Drafting Services ensure that every component is designed to exact specifications, reducing errors and improving efficiency.

-

Accuracy:

Professional draftsmen use specialized software like AutoCAD, Inventor, Microvellum, Cabinet Vision, 2020 Design to create precise designs that reflect the vision and measurements of the space. This eliminates guesswork and ensures that each piece of millwork fits perfectly.

-

Efficiency:

With clear, detailed shop drawings, communication between designers, manufacturers, and installers becomes streamlined. This reduces delays during the production and installation processes, helping to keep the project on schedule.

-

Cost Savings:

Millwork Shop Drawing Services help prevent costly mistakes by providing accurate, detailed plans that minimize errors in manufacturing and installation. This can save both time and money by reducing material waste and labor costs associated with fixing mistakes.

-

Enhanced Collaboration:

A detailed set of drawings ensures that everyone involved—whether it’s the woodworkers, millwork manufacturers, interior designers, or architects—is on the same page. This facilitates smooth collaboration throughout the project, ensuring that the final results align with your business’s needs.

-

Compliance and Standards:

Professional drafters are also well-versed in building codes and industry standards. Their designs ensure that your millwork meets all necessary regulations and safety requirements, further contributing to the overall quality and success of your project.

Current Trends and Innovations in Woodworking

The millwork and woodworking industries are evolving rapidly thanks to advances in technology, sustainability initiatives, and the push for more personalized designs. Here’s what’s defining the future:

1. Smarter Tools for Precision

Technology like CAD software and CNC machines is raising the bar for accuracy. Millwork shop drawing essentials are now more detailed and reliable, helping teams avoid mistakes. With 3D modeling, clients and fabricators can see and refine designs before production begins, saving time and resources.

2. Customization Takes the Lead

There’s a growing demand for unique, personalized millwork—be it cabinetry, moldings or built-ins tailored to specific needs. Shop drawings are bridging the gap between creative concepts and practical execution, allowing designers and clients to achieve results that fit both style and function.

3. Sustainability on the Rise

Green practices are becoming a priority. From reclaimed wood to low-VOC finishes, sustainable materials are now front and center. Shop drawings play a crucial role in optimizing material usage and minimizing waste, making projects more eco-friendly.

4. Collaboration Made Seamless

Real-time communication is getting boosted with digital tools. Shop drawings shared via cloud platforms allow architects, contractors and fabricators to stay aligned, reducing miscommunication and delays.

5. Efficiency is Everything

Automation and robotics are speeding up the design-to-production process without sacrificing quality. Detailed shop drawings are key to ensuring these advanced tools work smoothly, cutting down on rework and delivering projects on time and on budget.

Conclusion

Millwork and carpentry each play an important role in shaping a business space. Millwork brings precision and customization, while carpentry provides the structural foundation and flexibility needed on site. Together, they can create spaces that are not just functional, but also visually impressive and aligned with your needs.

When you combine these crafts with modern CAD software and sustainable materials, the results speak for themselves—efficient, high-quality spaces that stand the test of time. To make it all come together seamlessly, working with an expert Millwork Drafting Services provider is key. They’ll help you bring your vision to life with precision and care, creating a space that reflects your brand and delivers long-term value.

Turn Your Ideas into Reality

Create stunning, functional spaces with our expert drafting services.