Client Profile.

The client is an Irish designer, manufacturer and installer specializing in recycling and material waste handling equipment. Their cutting-edge design development solutions cater to both new as well as operative plants across Europe.

Business Need.

The client was working on improving existing designs as well as developing new designs for walkways, support structures and hoppers for ease in material handling and loading treatment. Each hopper had complex design involving several sheet metal parts bolted with each other. A small change in conveyer location by few centimeters led to major design rework in hoppers. It was time-consuming and erroneous.

For on-time delivery of error-free drawings for such complex structures, the client needed to bolster their team strength with additional CAD engineers and experts in plant layout.

Challenges.

Project engineers faced multiple processes challenges such as:

- Heavy input CAD files of complete plant that would sometime take up to 30-45 minutes just to download

- Accounting for collisions and design interdependence of conveyors, support structures, walkways, slope parameters to facilitate waste flow, and space constraints needed meticulous detailing

- Managing all design changes against a tight delivery

- Complexity of existing plant model demanded plant visits by offshore team to get the exact design references

Solution.

Plant assembly models with embedded sheet metal models of walkways and hoppers created in CREO with top-down approach were delivered to enable quick design changes in future. It also saved overall project time while meeting project milestones.

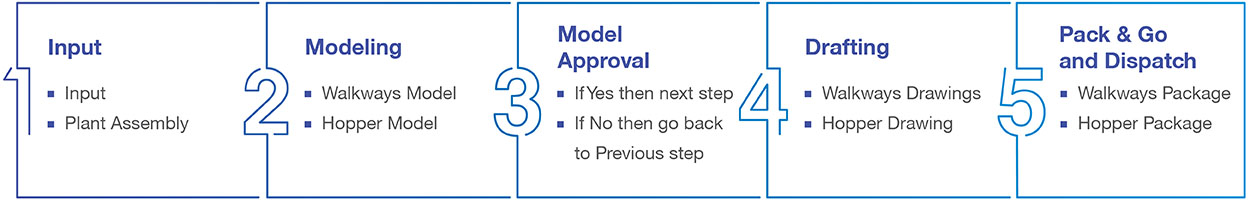

Approach.

The client shared overall input models and hand sketched design concepts with the project team to prepare manufacturing-ready models. A team of four CREO engineers worked on the project to deliver 3D models, STEP files, 2D manufacturing drawings along with part drawings and DXFs.

- Input files were extracted and loaded in CAD format received on emails as zip file attachment

- Overall solid models for walkways were converted to STEP files while for hoppers plant assemblies with conveyor, support, walkways etc. were shared to develop accurate hoppers for conveyer

- The team developed sheet metal models in CREO for walkways and hoppers for approvals and as per the tooling capabilities

- Top-down approach was adopted to easily incorporate ongoing changes as and when needed to adjust for the conveyor movement. It also improved designer engineers’ productivity significantly

- RFIs were raised to minimize assumptions, guesswork and keep the quality up to the mark

- Stringent quality audits were done against a predefined check list that included:

- Product impacting sheet should be either 3 or 5mm thickness; other metal sheets should be 2mm thick

- For vibrating equipment, the hopper should have a minimum 50 mm clearance with the surrounding structure

- Check for clashes within the hopper, with conveyor or the plant structures

- Maximum sheet size checked for all parts it should be 1250x2500mm or max 1500x4000mm and for 5mm thick maximum sheet size 2500x750mm

- Title block details, date, drawing number, description, etc.

- Final drawing files, PDF drawings, STEP file and DXFs with BOMs and 3D models were emailed to the client