- DriveWorks implementation requires thorough project scoping, data management, and user training.

- Key areas to focus on include model preparation, rules and logic setup, testing and validation, documentation, system integration, and user training.

- By following best practices, businesses can avoid common mistakes, maximize ROI, and achieve successful automation outcomes.

Table of Contents

- Avoid inadequate project scoping and planning

- Ensure proper model preparation standards

- Establish a solid data management strategy

- Avoid inconsistent rules and logic setup

- Prevent insufficient testing and validation

- Adopt complete documentation standards

- Address system integration and compatibility issues

- Prioritize user training requirements

- Wrapping up

DriveWorks implementation is often affected by poor project planning, inadequate data management, and insufficient user training. These challenges result in scope creep, system reliability issues, and reduced adoption rates, ultimately compromising the success of automation initiatives.

To overcome these obstacles, teams must focus on comprehensive project scoping, establish robust data management practices, and invest in thorough user-training programs. Implementing rigorous testing protocols across various scenarios and ensuring proper system integration are crucial. In addition, maintaining detailed documentation standards and validation procedures helps create a sustainable implementation framework.

In this article, we discuss techniques for avoiding costly mistakes, maintaining system integrity, and achieving higher user adoption rates. Leveraging these solutions when implementing DriveWorks will help you improve your design-to-manufacturing processes while maximizing your return on investment.

Avoid inadequate project scoping and planning

Thorough project scoping and meticulous planning are crucial for successful DriveWorks implementation. This crucial initial phase lays the foundation for a well-structured and efficient automation process.

A thorough scope definition should include detailed requirements analysis, stakeholder identification, and clear project boundaries to prevent scope creep during implementation. Creating a detailed scope management plan helps establish guidelines for defining and monitoring the project scope throughout the implementation lifecycle.

One of the most common DriveWorks implementation mistakes is failing to conduct thorough user needs assessments and process mapping before initiating the project. Successfully implementing DriveWorks requires understanding existing workflows, identifying automation opportunities and establishing measurable objectives aligned with business goals.

For successful implementation, it is crucial to create detailed documentation, set realistic timelines, and allocate adequate resources for the testing and validation phases. Custom training programs can enhance team productivity and reduce resistance to change.

You also need to establish clear communication channels, define roles and responsibilities, and create contingency plans for potential roadblocks during DriveWorks implementation.

Here’s an overview of what you should keep in mind:

Infrastructure

Ensure sufficient server capacity, bandwidth, and software compatibility.

Training

Develop custom training for different user groups on DriveWorks features and usage.

Integration

Assess challenges and plan for integrating DriveWorks with existing systems.

Communication

Establish clear communication channels for information sharing and collaboration.

Roles & Responsibilities

Define roles and responsibilities for project team members to ensure accountability.

Contingency Planning

Identify potential roadblocks and develop contingency plans to minimize disruptions.

Regular progress monitoring and systematic risk assessment help guarantee project success while maintaining flexibility for necessary adjustments throughout the implementation process.

Ensure proper model preparation standards

When setting up a DriveWorks configurator, inadequate model preparation leads to significant complications, reduced performance, and potential failures in the automation process, particularly when dealing with complex assemblies and manufacturing specifications.

The following are some ways in which you can avoid the common errors in DriveWorks setup related to model preparation:

- Consistent naming conventions: Establish and enforce consistent naming conventions for features, components and drawings. This improves model organization and makes it easier to create and manage DriveWorks rules.

- Well-structured design tables and equations: Design tables and equations should be organized logically and clearly documented. This ensures that DriveWorks can accurately capture and manipulate design parameters.

- Model relationships and dependencies: Pay close attention to the relationships and dependencies between different components and features within the model. This helps DriveWorks understand how changes to one element affect others.

- Complete documentation: Thoroughly document all modeling decisions, parameter constraints, and design intent. This documentation serves as a valuable resource for future maintenance and troubleshooting.

Establishing robust modeling standards before initiating DriveWorks implementation helps achieve smoother automation deployment and reduces the need for time-consuming revisions during later stages of project development.

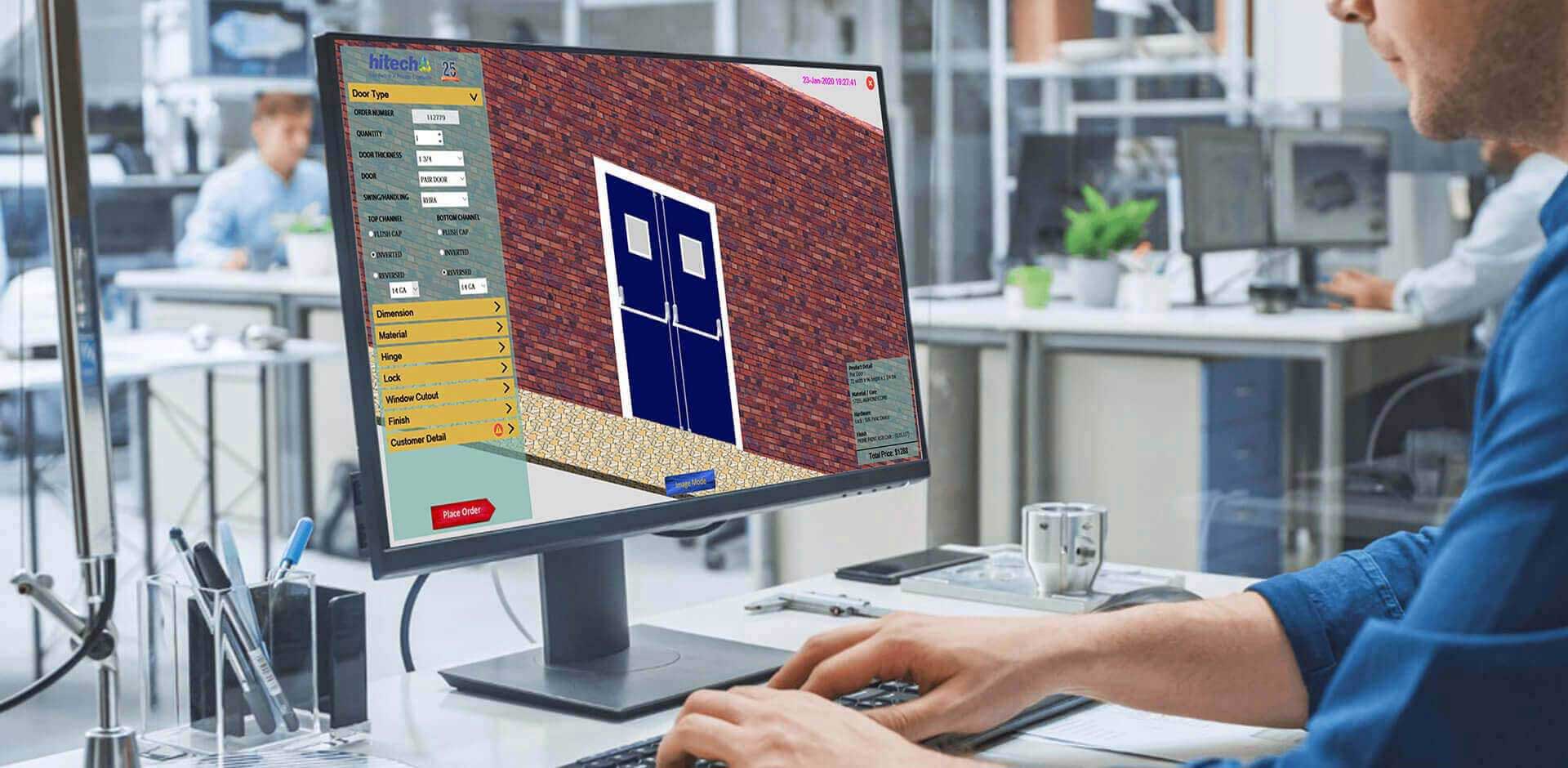

Accelerating Custom Washroom Design with a DriveWorks based 3D Visual Configurator

A UK-based designer and manufacturer of custom-made washroom cubicles sought to enhance their design process. The client required an interactive 3D interface to facilitate faster customization and improve design visualization.

HitechDigital developed a washroom configurator using DriveWorks, enabling the client’s design team to swiftly customize cubicles and panel designs. This tool auto-generated 3D previews of finalized models and manufacturing drawings, complete with Bills of Materials (BOMs), providing higher accuracy and greater interactivity for the sales team.

The final deliverables led to:

- Reduced sales-to-engineering cycle time from 10-15 days to just 3 hours

- Enhanced design accuracy

- Improved sales efficiency

Establish a solid data management strategy

Without proper data management protocols and structured information architecture, companies risk compromising their automation efficiency through inconsistent inputs, redundant specifications and unreliable outputs that can greatly impact project outcomes.

A thorough data management strategy for DriveWorks should incorporate the following critical elements:

- Centralized data repository with version control mechanisms to maintain consistency across all automated processes and prevent conflicting specifications.

- Standardized naming conventions and metadata frameworks that enable efficient searching, sorting, and categorization of project components.

- Regular data validation protocols to uphold accuracy, completeness, and integrity of specifications throughout the automation lifecycle.

- Systematic backup procedures and recovery plans to protect against data loss and maintain business continuity.

Implementing these strategic elements requires careful consideration of existing workflows, system architecture, and organizational requirements. Leveraging shared group environments helps enhance collaboration and data management for teams of three or more users working on long-term projects. The system’s Excel syntax integration provides additional flexibility when building and managing complex rule sets.

You should also establish clear protocols for data entry, maintenance, and archival processes, while guaranteeing scalability to accommodate future growth and extended functionality within the DriveWorks environment.

Avoid inconsistent rules and logic setup

When engineers and designers create rule structures without standardized protocols, the resulting automation can become fragmented, difficult to maintain, and prone to errors that compromise design integrity.

Following DriveWorks implementation best practices requires establishing clear naming conventions, implementing version control protocols, and maintaining detailed documentation of logical operations. Create modular and reusable rule sets to promote consistency and reduce redundancy.

DriveWorks’ Rules Builder interface simplifies rule construction while maximizing variable flexibility for enhanced customization options. Leveraging the powerful rules engine enables custom control over dimensions, features, and document management across the entire system.

Inconsistent logic patterns among different team members also result in conflicting rules that generate unexpected outcomes in the final design outputs. To mitigate these issues, companies should develop thorough rule-writing guidelines, implement regular peer reviews of logic structures, and maintain centralized documentation of all rule dependencies.

Prevent insufficient testing and validation

The complexity of DriveWorks projects demands rigorous testing across multiple scenarios, configurations and user inputs to guarantee reliable performance and accurate outputs. Custom reporting tools enable teams to monitor and analyze testing results effectively. Design automation tools help streamline the validation process while maintaining model integrity.

The following are the steps that you need to follow to guarantee adequate testing and validation:

- Systematically test each rule-and-form combination under various input conditions, documenting unexpected behaviors and edge cases.

- Validate generated models against established quality standards, checking for proper feature relationships and dimensional accuracy.

- Perform user acceptance testing with stakeholders from different departments to identify potential workflow bottlenecks.

- Implement thorough error handling and input validation to prevent system failures.

Regular testing cycles, particularly after implementing new features or modifications, help maintain system integrity and prevent costly errors from reaching production environments. Utilizing the Form Design Test Mode enables developers to verify input validations and dynamic form behavior before deployment.

This methodical approach to validation guarantees that automated processes consistently deliver accurate results while maintaining the flexibility needed for future system adaptations.

Adopt complete documentation standards

Comprehensive documentation is essential throughout the DriveWorks implementation process. It serves as a valuable resource for users, administrators and developers, enabling effective training, troubleshooting and maintenance.

Complete documentation provides a clear understanding of the system’s design, functionality, and logic. It helps identify and resolve issues quickly and ensures consistent knowledge transfer. Complete documentation also facilitates ongoing maintenance and updates by providing a clear record of the system’s architecture and configuration.

Key documentation elements for a DriveWorks implementation include:

- Model specifications: Detailed specifications for model structures, naming conventions, folder hierarchies, and workflows.

- Version control protocols: Documentation of version control procedures, file management practices, and change documentation processes.

- Design intent: Clear explanations of design intent, calculation methods, and the decision logic behind rules and automation processes.

- Technical specifications: Technical specifications detailing relationships between parameters, formulas, and model behaviors.

- Testing procedures: Records of testing procedures, validation criteria and test results.

- User manuals: User-friendly manuals and guides that provide step-by-step instructions and troubleshooting tips.

By prioritizing documentation, businesses ensure their DriveWorks implementation is well understood and easily maintained. This contributes to a more efficient, reliable and user-friendly automation solution.

Address system integration and compatibility issues

When implementing DriveWorks, you need to factor in the complexity of integrating the software with existing enterprise systems, particularly in environments where multiple software platforms need to communicate seamlessly.

The absence of a thorough integration strategy can lead to workflow disruptions, data synchronization issues, and reduced operational efficiency.

To avoid this, you must consider the following:

- Verify compatibility between DriveWorks versions and SOLIDWORKS releases, confirming that all necessary service packs and updates are properly coordinated.

- Assess network infrastructure requirements, including bandwidth capabilities, server configurations, and remote access protocols.

- Evaluate existing PDM/PLM systems integration points, particularly focusing on revision control and file management workflows.

- Document API dependencies and custom integration requirements for third-party software connections.

Understanding system dependencies and maintaining compatibility across platforms requires careful planning and regular assessment of integration points.

Prioritize user training requirements

To ensure a smooth and successful DriveWorks implementation, prioritize comprehensive user training. Don’t underestimate the importance of this step, even with experienced CAD users. Without proper guidance, users may struggle to adapt, leading to decreased efficiency and productivity.

Focus your training strategy on three key areas: technical functionality, workflow integration and troubleshooting. Provide users with hands-on experience in DriveWorks, covering form creation, rule development, and specification management. Clearly demonstrate how these elements integrate with your existing design processes.

Equip your users to overcome common implementation challenges by incorporating troubleshooting protocols into your training. Empower them to resolve issues independently by providing resources like documentation repositories, internal knowledge bases, and designated power users. Consider leveraging certified professionals for expert instruction and effective knowledge transfer.

Regularly assess user proficiency. This will help identify knowledge gaps and areas in which additional training is needed. This approach ensures your team maintains peak performance and maximizes the software’s potential.

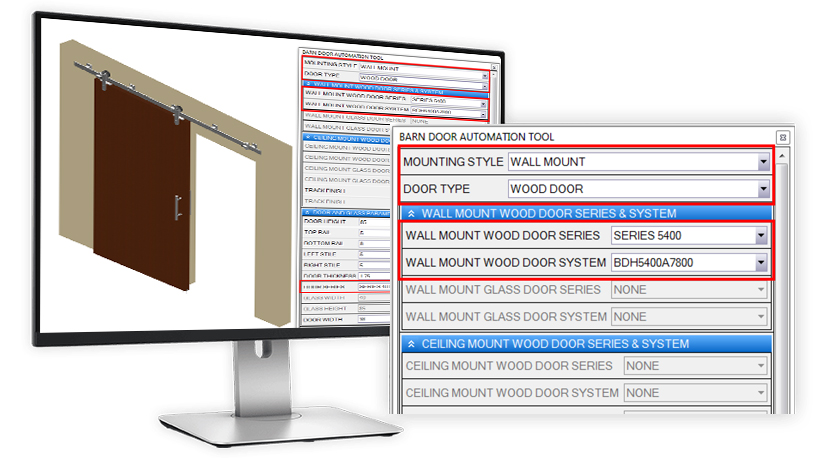

Design Automation Reduces Delivery Times by 70% for Door Manufacturer

A U.S.-based manufacturer specializing in metal and steel doors and frames sought to enhance operational efficiency. The client required solutions to reduce engineering time and service costs to manage increased production demands.

HitechDigital implemented design automation using SolidWorks and DriveWorks, transforming order processing and engineering workflows. This automation reduced engineering time by up to 80%, enabling the client to handle higher order volumes efficiently.

The final deliverables led to:

- Over 70% reduction in delivery times

- Approximately 40% decrease in design development costs

- Capacity to process over 10,000 orders per month

Wrapping up

Successful DriveWorks implementation requires careful attention to multiple critical factors, from thorough project scoping to robust system integration planning. You must establish clear model preparation standards, implement extensive training protocols, and develop consistent rules logic while maintaining proper documentation throughout the process.

You need to consider both current and future system requirements, factoring in upgrades, scalability needs, and evolving technology standards to confirm the long-term sustainability of your DriveWorks implementation. Through careful consideration of these essential elements and systematic testing procedures, you can avoid common pitfalls and achieve ideal results in your DriveWorks automation initiatives.

Automate sales and design with intuitive DriveWorks configurator

Reduce order errors and enhance customer engagement instantly