- Integrating DriveWorks with ERP systems allows custom manufacturers to achieve seamless data flow across business and engineering divisions, enabling data-driven decisions.

- To integrate the systems, manufacturers must engage in robust pre-integration planning and strategy, and consider using integration platforms to enhance data synchronization efficiency.

- SYSPRO and Navision are two leading ERP platforms that integrate seamlessly with DriveWorks, promoting greater competitiveness and enhanced efficiency for custom manufacturers.

Custom manufacturing industry strongly demands efficient design automation and integration of engineering design platforms with other broader business systems. Integration with systems like Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Material Requirements Planning (MRP), or Inventory Management Systems is they key for visibility within the organization. DriveWorks, as a leading design automation and sales configurator solution, plays a crucial role here in streamlining processes. Its seamless integration with leading ERP systems like Navision and SYSPRO offers greater visibility to custom product manufacturers.

Table of Contents

- DriveWorks and ERP integration: Need and Significance

- Pre-Integration Considerations

- Integration Strategies

- DriveWorks and ERP Systems: Step-by-Step Integration Guide

- A case in point: Integrating DriveWorks with SYSPRO

- A case in point: Integrating DriveWorks with Navision

- Managing and Maintaining the Integration

- Future Trends and Developments

DriveWorks and ERP integration: Need and Significance

In the custom manufacturing sector, integrating DriveWorks with ERP systems like Navision and SYSPRO ensures seamless data flow between engineering, finance, procurement and inventory teams for informed decision making.

In this highly customized industry, design specifications and sales quotation change with any change in customers. While DriveWorks can automate the sales-to-engineering cycles, ERP systems ensure optimized inventory in stocks for uninterrupted manufacturing and delivery.

Pre-Integration Considerations

Before beginning the integration of DriveWorks with Navision and SYSPRO, it’s important to consider a few key points, especially for DriveWorks users.

Start by assessing your project needs and goals. This step is vital for pinpointing the exact features you need from the integration. Understanding the technical aspects of Navision and SYSPRO is equally critical. Get to know their APIs, data structures, and compatibility with DriveWorks for a smoother workflow.

Next, focus on compliance and security. For custom products like doors, keeping data secure and meeting regulations is essential. Review the security measures in place, the ways data is encrypted and confirm that everything meets industry standards.

Taking these steps ensures that the integration aligns with specific business objectives, seamlessly merges technical infrastructures, and upholds stringent security measures. They set the stage for successful integration of these tools.

Integration Strategies

When planning to integrate DriveWorks with Navision and SYSPRO for discrete and custom manufacturing, several strategies can be used to achieve a seamless amalgamation of these systems.

You can choose from options like using APIs (Application Programming Interfaces), middleware, or integration platforms to connect the systems. It’s essential to test thoroughly, implement the integration step by step, and work closely with IT teams and stakeholders to ensure the integration supports the project’s goals.

You can also customize DriveWorks to increase efficiency. Adjusting workflows, setting up specific triggers for data synchronization and automating repetitive tasks can significantly improve the integration’s effectiveness.

By adopting these methods, you’ll create a more efficient link between DriveWorks and the ERP systems. This will help custom manufacturers to use the integration to increase productivity and streamline operations better.

Unleash the integrated power of design automation and ERP.

Streamline engineering operations with overall business needs.

DriveWorks and ERP Systems: Step-by-Step Integration Guide

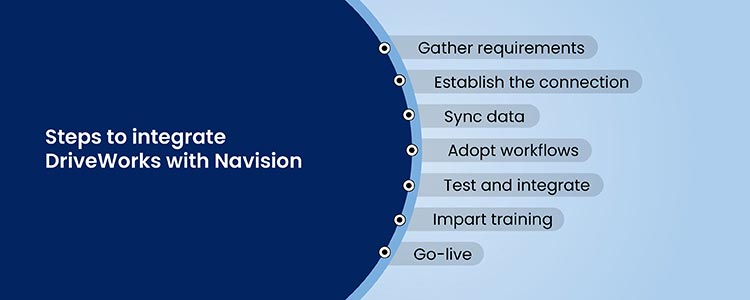

Part 1: Integrating DriveWorks with Navision

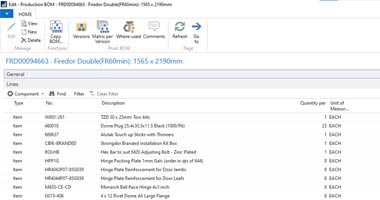

- Initial Setup and Requirements: Understanding the necessary software versions and hardware requirements is crucial. Ensure compatibility between DriveWorks and Navision versions and assess hardware capabilities for seamless integration. Verify network compatibility and set up appropriate access permissions for both systems.

- Establishing the Connection: Begin by outlining a step-by-step process to establish a secure and stable connection between DriveWorks and Navision. If required, configure APIs or middleware to facilitate communication between the systems. Detailed documentation and guidance on this setup process are essential.

- Data Mapping and Synchronization: Provide comprehensive guidelines for mapping data fields between DriveWorks and Navision, ensuring accurate and coherent data exchange. Establish synchronization schedules or triggers to automate data transfers at specified intervals or when specific events occur.

- Customization and Workflow Adaptation: Offer guidance on customizing the integration to align with the unique business processes of custom product manufacturing. Describe how to adapt workflows within DriveWorks to match the data structures and processes of Navision, ensuring a harmonious connection.

- Testing the Integration: Propose strategies for comprehensive testing to validate the integration’s functionality and data integrity. Offer troubleshooting advice to identify and resolve common integration issues that may arise during testing.

- User Training and Documentation: Develop training materials to educate users on the integrated system, ensuring they understand how to navigate and utilize the combined functionalities of DriveWorks and Navision. Additionally, create detailed documentation of the integration setup for future reference and troubleshooting.

- Go-Live and Monitoring: Outline the steps needed to transition the integrated system into live operation. Offer guidance on conducting final checks, executing the integration, and monitoring tools and practices to ensure ongoing smooth operation. Provide troubleshooting tips for any potential issues post-implementation, emphasizing proactive monitoring and support for sustained efficiency.

A comprehensive step-by-step integration guide following these stages will empower custom manufacturers using DriveWorks to successfully integrate it with Navision, streamlining their operations and enhancing overall efficiency in the manufacturing process.

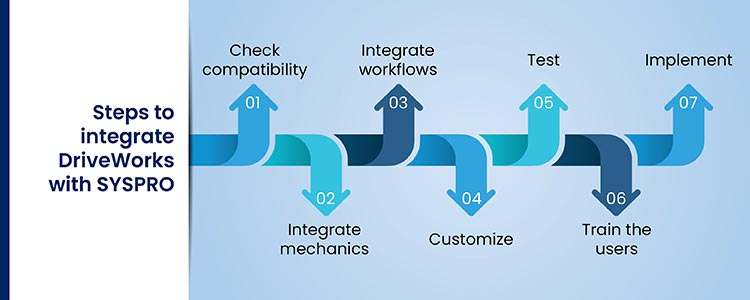

Part 2: Integrating DriveWorks with SYSPRO

- Preparation and Compatibility Check: Begin by verifying the compatibility between DriveWorks and SYSPRO versions. Ensure that the infrastructure and network meet the requirements for a successful integration. Assess the compatibility of hardware and software components to avoid any potential compatibility issues.

- Integration Mechanics: Provide a step-by-step guide detailing the process of connecting DriveWorks with SYSPRO. If necessary, offer instructions for installing any required software or middleware to facilitate the integration process. Clear documentation is essential for a smooth setup.

- Data Exchange and Workflow Integration: Outline a detailed process for setting up data exchange paths between DriveWorks and SYSPRO. This should include mapping data fields and establishing synchronization schedules. Describe how to align DriveWorks’ automated workflows with SYSPRO’s processes for seamless integration.

- Customization for Business Needs: Guide users on tailoring the integration to suit unique business needs of custom manufacturers. Offer insights into modifying and creating custom fields or functions within DriveWorks and SYSPRO to accommodate specific requirements.

- Comprehensive Testing: Provide methods and strategies for comprehensive testing of the integrated system to ensure functionality and reliability. Offer guidance on identifying and resolving potential conflicts or errors that may arise during the testing phase.

- Training and Documentation for Users: Develop user guides and conduct training sessions to familiarize users with the integrated system’s functionalities. Additionally, create detailed documentation outlining the setup and functioning of the integrated system for future reference and troubleshooting.

- Implementation and Ongoing Support: Lay out strategies for a smooth implementation process, including checks and procedures before going live with the integrated system. Set up support structures to address post-implementation queries and issues, ensuring ongoing support and maintenance for users utilizing the integrated DriveWorks-SYSPRO system.

By following these comprehensive steps, custom manufacturers using DriveWorks can efficiently integrate it with SYSPRO, optimizing their operations and leveraging the combined functionalities to enhance productivity and streamline processes in the industry.

A case in point: Integrating DriveWorks with SYSPRO

A custom glass product manufacturer, in the process of implementing a SYSPRO ERP system, encountered challenges with controlling and evaluating input values, essential for the system’s accuracy. To address these issues, the manufacturer approached the HitechDigital team to develop a UI configurator that would enable precise evaluation of each input, thereby ensuring accurate pricing calculations and quote generation.

The HitechDigital team designed a web-based UI form, integrating DriveWorks UI controls with SYSPRO tables through readily available DriveWorks plugin. This integration not only facilitated the conversion of quotes into orders but also streamlined price calculation, quote preparation, and email functionalities for sales personnel. Additionally, DriveWorks Autopilot was integrated to automate the feeding of quote data into SYSPRO as an order once the customer has confirmed it. The result was a functional DriveWorks project, deployed at the client’s site, which significantly enhanced the efficiency and accuracy of their ERP system.

Plugin Settings for connecting DriveWorks & SYSPRO

Plugin Settings for connecting DriveWorks & SYSPRO

Export details to SYSPRO through DriveWorks

Export details to SYSPRO through DriveWorks

Managing and Maintaining the Integration

Effectively managing and maintaining the integrated system of DriveWorks with Navision and SYSPRO requires a strategic approach to ensure sustained efficiency. Continuous management involves establishing protocols for ongoing monitoring, regular performance assessments, and proactive troubleshooting.

Implementing a structured maintenance plan that includes regular updates and upgrades is vital to keep the integrated systems synchronized and secure. This plan should encompass scheduled software updates, patch installations, and version upgrades for DriveWorks, Navision, and SYSPRO, ensuring compatibility and leveraging new features for improved functionality.

Consistent performance monitoring is crucial to identify any discrepancies or bottlenecks within the integrated system, allowing for timely adjustments and optimizations. By employing these strategies, custom product manufacturers utilizing DriveWorks can maintain a seamlessly integrated system, maximizing its efficiency and staying ahead in their industry.

Future Trends and Developments

DriveWorks is likely to roll out enhanced automation capabilities, improved user interfaces, and expanded compatibility with new technologies. For custom product manufacturers like doors and windows, architectural component manufacturers, and furniture, staying ahead means keeping an eye on these updates.

Navision and SYSPRO might introduce better workflow management, AI-driven analytics, and cloud-based solutions to enhance scalability and accessibility. These developments could significantly impact future integrations by offering better connectivity and data exchange capabilities, and improved interoperability.

Preparing for these changes is crucial. Manufacturers must stay on top of updates, check compatibility with existing systems and strategize to leverage new features to improve integration.

Staying ahead of the curve allows manufacturers to tap into the full potential of these systems in their integrated environment, paving the way for enhanced efficiency and competitiveness.

Conclusion

Integrating DriveWorks with wider enterprise systems is a game-changer for discrete and bespoke manufacturers. This integration allows your business to fine-tune operations, offer more customization options, make better decisions, cut costs, and secure a leading position in the market. If you’re a CEO or CTO, integrating DriveWorks with ERP systems is a key move to ensure your manufacturing processes stay ahead of the curve and propel your business to new heights.

Empower your engineering teams with cohesive decision-making.

Get insights into organization-wide resources for custom manufacturing.