- Applying resilient BIM validation techniques and strong Scan-to-BIM quality assurance practices during renovation and retrofit projects improves project management, drives greater transparency, and supports effective remote collaboration.

- Leveraging advanced quality control strategies—including automation, Artificial Intelligence (AI), and Machine Learning (ML) for classification, segmentation, and quality enhancement—helps achieve higher accuracy, adaptability, and operational efficiency.

- Following best practices for quality control—such as point cloud registration checks, model accuracy audits, and Revit-based validation—ensures greater precision, improved workflow efficiency, and enhanced reliability across Scan-to-BIM processes.

Table of Contents

- Top 5 challenges in Scan to BIM conversion

- The role of Point Cloud to BIM in renovation and retrofitting projects

- Quality control measures in 3D Scan to BIM conversion

- How to maintain the accuracy of your Scan to BIM models

- Understanding the Scan to BIM process

- Top 3 quality control techniques for Scan to BIM

- Proven validation techniques for accurate As-Built BIM models

- Common mistakes to avoid in Revit Scan to BIM conversion

- Top trends in validation and QC for Scan to BIM conversion

- Conclusion

In renovation and retrofitting projects, modeling accuracy sets the foundation for reliable outcomes. Advanced scanning can’t compensate for validation gaps — when point cloud data is noisy or misaligned, the resulting BIM model is at risk.

These issues raise coordination risks and inflate costs, particularly in legacy sites. Industry studies estimate that up to 14% of model rework stems directly from problems in scan accuracy and traceability. If teams don’t catch these issues early through validation, they ripple into construction documents, clash coordination, and site workflows.

To prevent these breakdowns, project teams must embed validation logic throughout the Scan to BIM workflow. This means leveraging the expertise of point cloud to BIM service providers for checking scan resolution, enforcing alignment, verifying spatial logic, and tracing every model element back to as-built site data.

This article breaks down recurring problems that impact model accuracy and walks through a series of BIM validation techniques designed to reduce drift, limit rework, and meet LOD 300 expectations. Understand these issues and their solutions helps you build 3D BIM models that are accurate, field-ready, auditable, and shareable across teams.

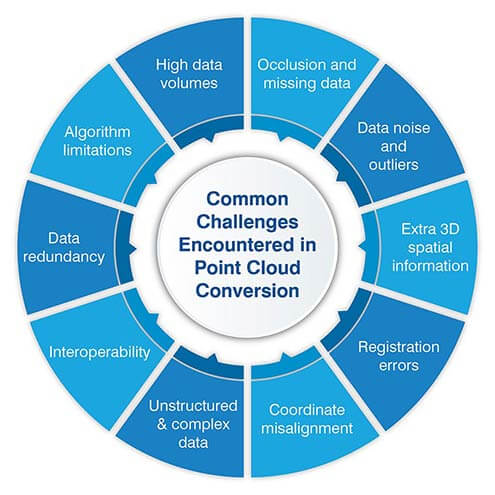

Top 5 challenges in Scan to BIM conversion

Scan-to-BIM conversion turns 3D scanned data into detailed digital models used for BIM and CAD projects. It’s how field data becomes buildable models. But the workflow is sensitive to multiple risks:

- Incomplete or noisy point cloud data, which can leave gaps and reduce model precision, especially when targeting ±2mm accuracy

- Complex building features, such as curved walls or detailed ornaments, that are difficult to model exactly at LOD 400-500 standards

- Errors introduced by human judgment during manual modeling, leading to inconsistencies across the model

- Limits of modeling software when handling very detailed geometry or managing extremely large point cloud files (over 20GB)

- Missing standardized workflows, which can result in uneven model quality and make projects fall short of ISO 19650 requirements

To control these risks before modeling begins, validation tools are used to check scan density, test alignment across frames, and log deviations.

The role of Point Cloud to BIM in renovation and retrofitting projects

Point cloud to BIM services are critical for creating accurate as-built BIM models, especially in renovation work. These services turn high-density scan data into geometry that can be coordinated, clashed, and approved. Most projects aim for LOD 300, which supports field verification and permit documentation.

When handled correctly, point cloud modeling provides a reliable foundation for decision-making. Teams catch structural irregularities, resolve interference early, and schedule tasks based on the actual site. QA logs, metadata tags, and alignment records are captured in CDE templates to support traceability.

When teams convert point cloud to 3D model using validated workflows, they deliver BIM models ready for planning and coordination.

Quality control measures in 3D Scan to BIM conversion

In Scan to BIM workflows, quality control is what transforms a raw 3D model into something accurate, reliable, and usable for construction design.

As part of Scan to BIM best practices, quality assurance addresses the gaps, noise, and distortions found in point cloud data captured through laser scanning or photogrammetry. If left unchecked, these issues pass into the model and eventually surface during coordination, leading to rework, clashes, or change orders.

During the Construction Documentation phase, validation ensures that what’s being modeled still reflects the site. It also links every element in the model back to its scan source, creating an audit trail that project teams rely on for approval and coordination. This traceability is what allows the model to function as a trusted deliverable—not just a drawing set.

Learn how Point cloud to BIM can streamline your building processes.

- Establish an accurate geospatial context for point cloud data.

- Simplify and optimize mesh representations of point clouds.

- Implement rigorous quality control procedures throughout the process.

- Adopt an iterative approach to modeling based on ongoing analysis.

How to maintain the accuracy of your Scan to BIM models

Several obstacles affect model accuracy in Scan to BIM projects. If they aren’t addressed through a clear QA process, their effects compound across later phases Below are five observed challenges in the accuracy of BIM models from scanned data:

- Point clouds with noise or missing data distort the geometry and require careful registration checks to anchor measurements

- Architectural irregularities like curved walls or legacy details resist standard modeling tools and must be flagged for manual refinement

- Inconsistent human judgment during modeling causes variation across disciplines

- Tool overload – some software platforms stall under heavy scan density, leading to skipped validations

- Missing workflow consensus results in uneven standards, which QA routines are meant to normalize

Understanding the Scan to BIM process

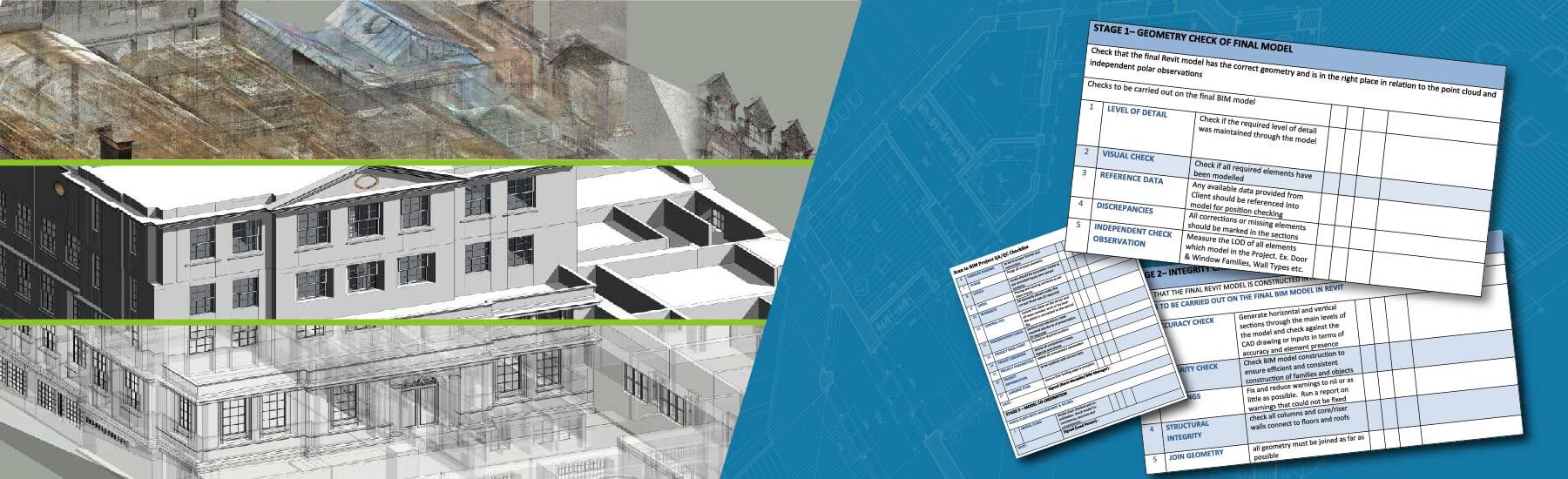

At its core, Scan to BIM links the built environment to the model-based workflows that drive planning, approvals, and handover. The process begins with capturing site conditions, processing the point cloud, and importing it into Revit. This step launches the Revit Scan to BIM workflow, where geometry becomes data and physical structure becomes model logic.

Scan alignment techniques—like control point triangulation and overlap correction—ensure that all modeling stems from a spatially accurate foundation. This consistency is what allows the resulting model to serve as both a coordination platform and a handover deliverable.

Top 3 quality control techniques for Scan to BIM

Ensuring high-quality results in Scan to BIM renovation and retrofit projects is critical for achieving greater accuracy, better decision-making, and overall project reliability. Quality assurance techniques used in Scan to BIM workflows help catch and fix errors early in the design phase, which reduces the risk of costly rework and strengthens the integrity of the 3D model.

Outlined below are three widely used methods that help maintain accuracy and consistency throughout the Scan to BIM process.

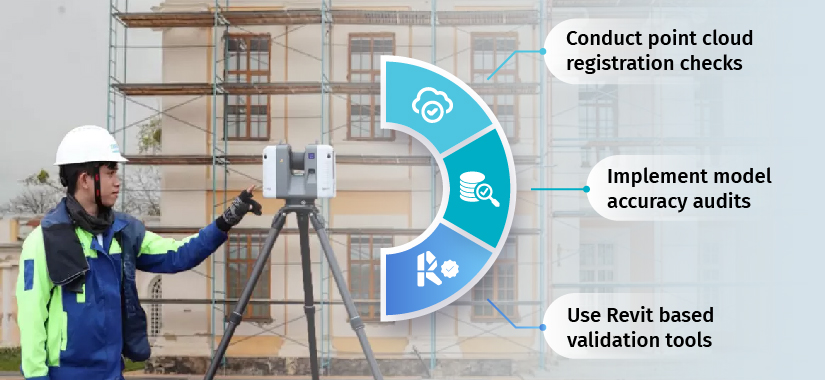

Conduct point cloud registration checks

Each scan must align to the same coordinate grid. Tools like Leica Cyclone or Faro Scene compare residual error thresholds and log alignment quality. These audits detect drift early and prevent it from creeping into spatial layouts. Registration audits use section cuts and error bands to validate scan alignment against reference geometry.

Implement model accuracy audits

Accuracy audits involve systematically reviewing the Point Cloud to BIM model against the original point cloud data to check for geometric precision. This method helps flag deviations, misinterpretations, or missing elements, ensuring that the model accurately reflects real-world As-Built conditions.

By conducting audits at every stage of the project, teams can catch errors early and maintain high-quality standards throughout the process. Building regular audit steps into workflows helps preserve model integrity and reduces the risk of costly rework and coordination issues.

Use Revit based validation tools

Revit-driven validation tools provide built-in or add-on capabilities to check the accuracy and compliance of Scan to BIM models. These tools help teams spot mismatches between 3D model elements and the original point cloud data, verify adherence to design standards, and automate clash detection.

By using Revit for model validation, teams can streamline quality control within a familiar platform. Automation options like Dynamo scripts, custom APIs, and integrated tools make it easier to ensure that the final model meets both project requirements and industry standards.

Proven validation techniques for accurate As-Built BIM models

For accurate as-built BIM modeling, the validation methods we use need to ensure real world conditions are taken into account. Validation techniques define the level to which we can reliably verify geometry, and align the 3D model with actual site realities by detecting conflicts early. Taken together, the different validation methods and techniques provide the base for creating 3D models, that prevent rework while meeting all project requirements.

Perform clash detection

Clash detection is the process, and technique, through which we spot spatial interferences between designs presented by different building trades. In every scan to BIM model, we need to perform clash detection both manually and with tools.

Automated clash tests can be run with Navisworks Manage or Solibri Model Checker. Conducting automated clash tests during early design phases (LOD 200-300) helps teams to catch errors that require manual review. This early detection of design errors helps build an interference-fee BIM model that mirrors existing layouts. It improves trade coordination and cuts down the need for further modifications while construction gets going.

Assess dimensional accuracy vs tolerance

Another important part of as-built BIM modeling is checking the modeled dimensions against the original scan data. This step uses set tolerance limits—usually between ±20 mm and ±30 mm, depending on the project’s requirements. It ensures that each modeled element matches its real-world counterpart as closely as possible.

Usually, software like Verity or CloudCompare is used to flag any dimensional deviation beyond accepted limits. Any dimensional mismatch needs to be corrected with urgency to maintain overall integrity of the BIM model. This is especially crucial in the creation of scan to BIM models for renovation or retrofitting projects.

Carry our real-world alignment

Once dimensional checks are over, georeferenced checks are used to ensure the as-built model accurately represents the site conditions and building coordinates. This is a crucial step for integrating the 3D model data into project systems like GIS. Accurate georeferenced alignment enables long term asset management, accurate survey coordination, and reliable on site application of BIM.

Common mistakes to avoid in Revit Scan to BIM conversion

Just using tools and techniques aren’t enough, because mistakes will slip through and compromise outcomes, unless the techniques are applied methodically and via a structured framework.

Key pitfalls include:

- Ignoring cleaning up of point clouds before starting modeling activities. This leads to noise artifacts that affect mesh generation

- Overlooking dimensional accuracy referencing with documented data sources that are verified by QA reports

- Adding unnecessary details that result in over-modeling and create inefficiencies beyond required LOD levels

- Applying inconsistent LODs across different elements without proper reference to BEP standards

- Neglecting regular quality audits throughout conversion stages—including failures in conducting interim COBie export checks

Teams implementing ISO 19650-compliant processes make it a point to catch these errors early, and thus achieve greater control over deliverable consistency. They enforce accuracy at every stage, because waiting to correct issues post-delivery is a far more resource-intensive process and requires extensive revalidation cycles.

Top trends in validation and QC for Scan to BIM conversion

As Scan-to-BIM technology moves forward, validation techniques and quality control tools are becoming faster, smarter, and more accurate—better suited for today’s increasingly complex building documentation needs.

AI-Driven Automated Quality Checks

AI-powered validation systems now automatically detect inconsistencies between BIM models and source point cloud data, dramatically cutting manual review times. While these systems handle routine checks like pattern recognition, geometry error detection, and component placement verification, human expertise remains essential for interpreting complex geometry and final decision-making.

Rule-Based and Semantic Validation

After AI-driven checks, semantic and rule-based validation ensures As-Built models meet logical interaction rules and project standards. These systems verify component positioning, geometric accuracy, and classification, automating compliance with ISO 19650 and reinforcing model fidelity and data integrity.

Real-Time Validation via Cloud Collaboration

Today’s cloud platforms allow both real-time and asynchronous validation by continuously comparing point cloud data against evolving BIM models. This capability helps teams quickly identify issues, maintain version control, and reduce rework—all within a transparent, collaborative environment spanning multiple locations and time zones

Conclusion

Quality control and validation are central to successful Point Cloud-to-BIM conversion projects. They ensure that resulting models are accurate, reliable, and usable—directly impacting workflow efficiency, decision-making quality, and stakeholder confidence across a project’s lifecycle.

As technologies continue to advance, validation processes will become even more refined. AI and machine learning integration promises reduced project costs, compressed schedules, and improved as-built performance parameters for owners and operators.

Looking ahead, Scan-to-BIM conversion is poised to drive innovation across the architecture, engineering, and construction industries—delivering consistently better outcomes for every stakeholder involved, from designers to facility managers.

Convert your Point Cloud data into accurate Revit 3D models.

Streamline your designing processes by transforming your 3D laser scans into precise and detailed Revit models.