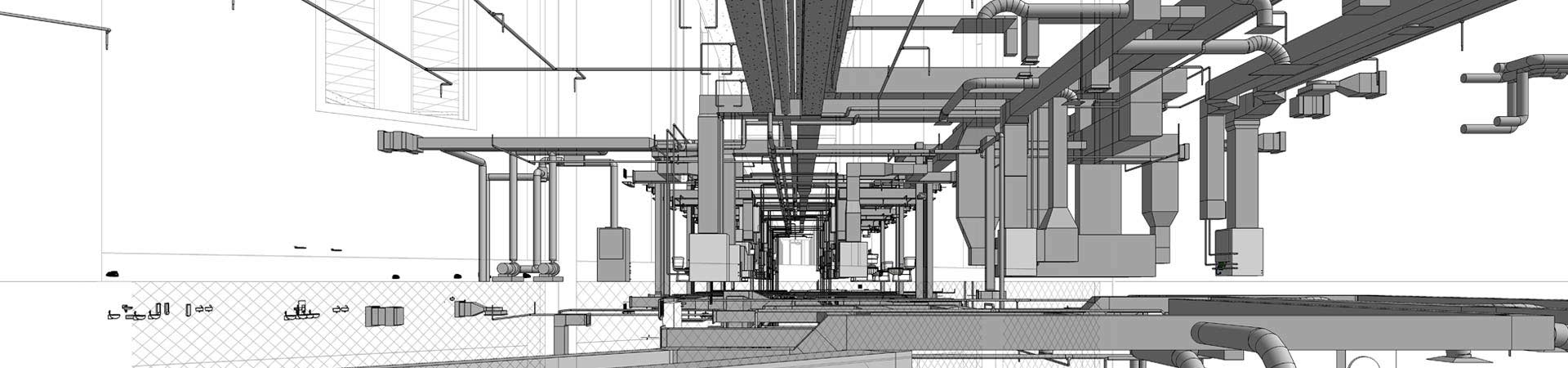

- MEP shop drawings extracted from coordinated 3D models are comprehensive and information-rich.

- BIM-based MEP shop drawings ensure clash-free fabrication and installation.

- MEP shop drawings help in precise material planning and procurement.

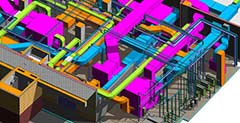

Shop drawings extracted from 3D BIM models carry MEP (Mechanical, Electrical, and Plumbing) technical data needed for on-site installation. Building contractors bank on MEP shop drawing services for easy accessibility to all project data. These include quantities and dimensions needed for fabrication, installation, and maintenance.

MEP coordination shop drawings are also crucial for modern project collaboration and coordination. They help to view and resolve all architectural, structural, and civil shop requirements within a single platform.

The “IM” in BIM is a crucial differentiator between legacy 2D and modern 3D modeling.

Geometric information like height of MEP components, and non-geometric information like specifications and characteristics modeled within a Common Data Environment, improve design, installation, and maintenance. Revit MEP shop drawings generated from 3D models ensure error-free final product assembly.

In this article, we discuss the top 5 roadblocks faced with legacy methods and benefits of using BIM in pre-construction workflows to create MEP shop drawings.

What are MEP shop drawings?

MEP shop drawings guide the field installation of mechanical, engineering and plumbing systems. They take into account architectural, structural, mechanical, plumbing and other design requirements for onsite assembly, installation and fabrication. MEP shop drawings include geometric information like height of MEP components. They also carry non-geometric information like specifications and characteristics modeled within a Common Data Environment. This improves design, installation, and maintenance.

Revit MEP shop drawings generated from 3D models ensure error-free final product assembly. They provide accurate specifications, including dimensions of components and fittings for piping connections.

Why adopt BIM: 5 legacy CAD MEP drawing roadblocks

MEP shop drawings generated through orthodox methods create several challenges. These come from data-deficient CAD or hand-sketched drawings that carry errors and miss information. Common challenges in executing projects with legacy CAD include:

- Low visualization across projects leading to loss of control, rework, project delays, and cost overruns

- Greater chances of clashes between various architectural, structural or MEP systems during installation leading to costly rework and project setbacks

- Inaccurate fabrication of MEP components, giving rise to installation problems, reworks, and cost overruns

- Communication gap within various trades leads to faulty pre-construction planning

- Inaccurate material planning and procurement, causing material waste or shortage, on-site delays, and cost overages

5 ways MEP shop drawings created with BIM increase project efficiency

1. Visualize entire projects with 3D models

MEP contractors can use BIM to get a complete view of MEP volumes and components in the design phase. Plumbing arrangements and ventilation systems require accurate connections and arrangements for disparate systems to function as a consolidated unit. And full control of the project scope within a common data environment with updated building information transforms coordination capacities.

Well-coordinated shop drawings can help clients garner 40% enhancement in scheduling and 50% cost savings.

2. Reduce MEP system installation clashes

The greatest advantage of BIM model-based MEP shop drawings is pre-emptive clash detection. The ability to identify and resolve clashes of MEP components within a 3D model generates error-free and data-validated shop drawings. These clash-free shop drawings reduce reworks and project delays during onsite MEP installation.

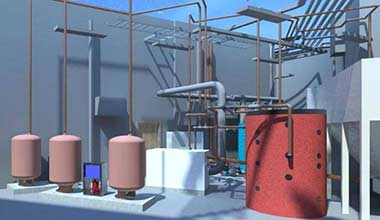

3. Ensure better MEP component fabrication

Data-rich, accurate, and error-free MEP shop drawings ensure that every MEP component is fabricated accurately. And precise fabrication of MEP components leads to better installation, reduction in change orders, and enables contractors to meet deadlines.

Learn how accurate construction drawings helped a UAE-based architectural consultant gain seamless fabrication and installation of MEP components.

3D MEP Modeling Revit

3D MEP Modeling Revit

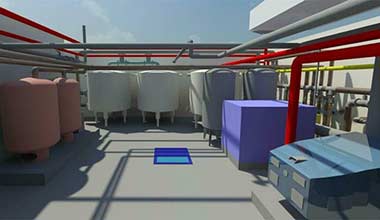

MEP 3D Modeling for Plant Room

MEP 3D Modeling for Plant Room

4. Improve collaborative pre-construction planning

Collaboration between teams using the 3D model in BIM improves design prototyping. Generative design, Dynamo automation, and the use of Revit libraries augment pre-construction planning. And the prototypes built with BIM processes and tools are data-rich, QC-approved, and improve planning.

Learn how a general consulting firm saved $7 million in 6 months with clash-free MEP models and MEP shop drawings.

BIM Clash Detection

BIM Clash Detection

Clash Resoution

Clash Resoution

MEP Clash Detection

MEP Clash Detection

5. Conduct superior material planning and procurement

3D BIM models loaded with pre-construction data promote accurate material planning through precise quantity takeoffs and cost estimation (5D). Accurate specifications of quantities of MEP components in 3D models reduce material waste and prevent delays and cost overruns.

Learn how a project management solutions firm gained accurate materials for takeoff and construction scheduling.

AI will define the future of MEP shop drawings

The use of AI has enhanced construction through a significant reduction in labor hours and greater construction accuracy. This has improved efficiency, better data validity, and coordination within MEP drawings. AI in BIM helps in decision-making, scheduling, and forecasting. It provides a series of benefits in planning, designing, installation, and maintenance, such as

- Cost-effective planning and prevention to negate over budgeting

- Better MEP design and installation through generative design

- Preemptive risk reduction for construction management and projects

- Improvements in job site productivity

- Enhancement of construction safety

“The application of AI, robotics, and IoT in construction has produced an overall reduction of 20% in project costs and expenses. AI can be adopted to improve the planning and design of MEP network routing for MEP systems.”

Conclusion

The task of generating MEP shop drawings for large projects requires deep experience in MEP drafting and MEP BIM services. Advanced BIM tools and processes ensure a better understanding of MEP details. And this leads to error-free fabrication and installation. Further, bespoke MEP drawings serve as a solid foundation to produce a clear picture, promote systematic planning, and meet deadlines.