- BIM services help concrete contractors visualize the complete structure in the preconstruction phase using accurate and data-driven 3D models.

- The application of BIM workflows and tools identifies clashes early on to work efficiently and mitigate delays based on unpredicted problems.

- Concrete contractors can gain an in-depth view of material needs and project milestones, which improves planning, reduces waste and ensures accurate cost estimates.

Table of Contents

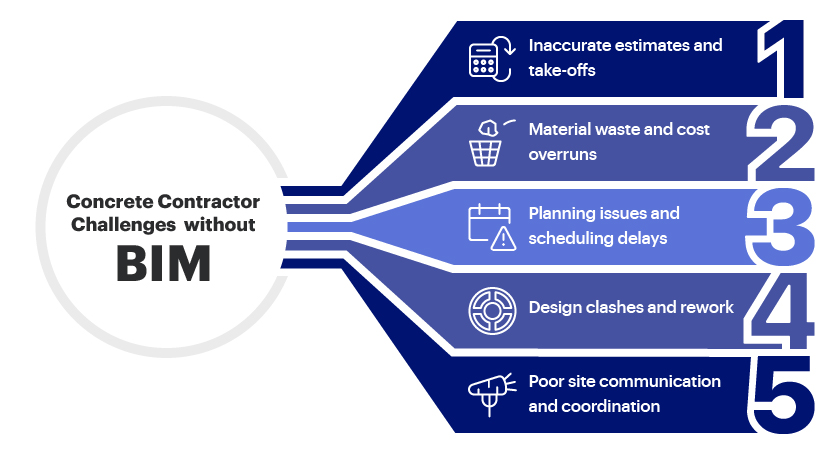

- Key obstacles concrete contractors face in the absence of BIM services

- Top 5 ways BIM services can improve project outcomes for concrete contractors

- Real-world case-studies exhibiting the positive impact of BIM services for concrete contractors

- The use of BIM processes and tools in concrete projects enriched with evolving technologies

- Conclusion

Precast contractors can successfully create and manage 3D precast models by using advanced BIM workflows. Such workflows usually involve tools like Revit and Navisworks, and cloud-collaboration platforms like BIM 360. These tools help concrete contractors implement BIM, control spatial relationships more skillfully through design-integrated geometry, and enhance collaboration.

However, advanced BIM workflows have multiple curves, including learning, infrastructure, human resources, troubleshooting, and teething issues. BIM services help contractors bypass these barriers and go straight into BIM implementation in production workflows.

Here, we have tried to assess the advantages of BIM services, including precise quantity take-offs, improved cost savings, better planning, and other benefits that make BIM implementation in concrete projects highly significant.

Based on a study by Global Market Insights, the precast concrete economy will reach $168.17 billion by 2026. This is not possible to sustain without granular BIM adoption in workflows, and those who are ahead of the technology curve will naturally grab a bigger share of the opportunities.

Source: GMinsights

Source: GMinsights

Key obstacles concrete contractors face in the absence of BIM services

The lack of BIM services and attempts to do everything in-house often result in debacles like cost-estimation errors and unexpected material waste. Project delays become an expected part of operations, as planning without BIM services usually takes more time and expertise, and even then, such planning fails to preempt most of the errors that BIM could have caught and remedied much faster. BIM services also help to solve recurrent issues like poor coordination and overlooked design clashes that manifest on site.

Top 5 ways BIM services can improve project outcomes for concrete contractors

Concrete contractors can leverage data-driven BIM services to utilize precise project data, optimize planning, and coordinate in real time. Tools used in the BIM framework, including Revit, Navisworks, etc., can reduce errors, enhance material use, and improve cost control.

1. Calculate accurate quantity takeoffs and cost estimates with 3D precast models

Using BIM for concrete projects based on 3D models can produce accurate material takeoffs and cut errors. It helps concrete contractors and manufacturers improve resource use, while real-time cost analytics induces accurate budgeting and greater efficiency.

-

Improve material estimation accuracy

Utilizing 3D models, concrete contractors can extract exact material calculations and eliminate manual intervention. 3D precast models created in Revit and coordinated in Navisworks can produce accurate Quantity takeoffs. These capabilities support concrete contractors to achieve greater project efficiency and serve the project as intended.

-

Eliminate higher material waste and the need for overordering

BIM enhances the use of materials to create concrete precasts by extracting accurate material estimates to avoid over-ordering. This ensures lower costs and leads to sustainable construction through a reduction in change orders.

-

Leverage comprehensive and real-time cost analytics

BIM tools like Revit help concrete contractors use the 3D precast model to achieve cost tracking in real time. This is done by using material and labor data within the Revit algorithm. Parametric modeling capabilities can dynamically modify estimates, prevent cost overruns and boost financial efficiency.

2. Reduce waste with BIM-based tools

Tools like Revit support concrete contractors by eliminating material waste and condense disposal costs. Prefabrication drawings extracted from coordinated and clash-free 3D models reduce material and labor costs, providing cost savings.

-

Minimize material waste with accurate quantity takeoffs

Accurate 3D modeling in BIM using Revit provides stakeholders with precise material calculations, reduces over-ordering, and prevents material shortages. This reduces concrete waste, lowers disposal costs, and encourages sustainable precast concrete practices for higher resource efficiency across a project.

-

Lower labor and material costs with BIM-enabled prefabrication and formwork design

BIM makes prefabrication and formwork design seamless with optimized material use and a significant reduction in labor time. Accuracy within 3D precast models ensures precise and data-driven member prefabrication, lower errors, and accelerated construction schedules.

-

Coordinate models and improve scheduling to prevent cost overruns and reduce design risks

Creating precast models in Revit at LOD 450 while using capabilities like model coordination and scheduling, flagging interferences to mitigate rework creates a positive project impact. Timeline improvements, delay prevention, reduction in cost overruns, and removal of design risks ensure projects stay within planned budgets and are handed over on time.

How are BIM and digital twins used in top construction projects?

- BIM and Digital Twins provide unique yet complementary capabilities.

- BIM focuses on design and construction; Digital Twins enable real-time monitoring and predictive maintenance.

- Integrating BIM and Digital Twins enhances decision-making, asset management, sustainability, and efficiency.

3. Improve planning and scheduling with 4D BIM

4D BIM improves project timelines for precast contractors by aligning various construction phases with BBS. It improves concrete pours, curing, and equipment usage to achieve precast efficiency.

-

Refine project timelines with visual construction sequencing (4D BIM)

4D BIM includes time-based visual sequencing using the Timeliner tool in Navisworks, which improves project timelines. It harmonizes various construction phases and produces accurate Bar Bending Schedules (BBS), BOQs, and BOMs to ensure planning is accurate and conflicts are resolved.

-

Improve pours, curing, and equipment use with coordinated and interference-free 3D models

Coordinated and clash-free 3D models improve pour cycles, equipment usage, and the accuracy of curing schedules. Coordinating formwork and rebar placement with Bar Bending Schedules (BBS) leads to lower waste, greater productivity, and faster construction. Furthermore, RFI standardization mitigates scheduling problems for structural members.

-

Prevent delays and idle time on site

Clash detection and sequencing using Navisworks eliminate delays by resolving conflicts for rebar, formwork, and MEP elements in the preconstruction stage. Accurate BBS and scheduling lowers idle equipment time, simplifies workflows, and ensures project progress, while reducing project downtime.

4. Detect clashes with BIM tools to mitigate reworks

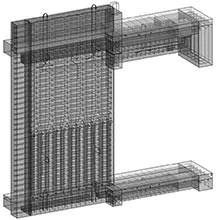

Using clash detection tools like Navisworks lowers rework through conflict identification and resolution. Thorough assessment of coordinated 3D models pinpoints various clashes, including spatial, geometric, system, code compliance, material, etc. Expedited resolution of these clashes before they manifest onsite can help concrete contractors save costly structural rework.

-

Resolve interdisciplinary clashes using a coordinated 3D precast model

Identification and resolution of clashes in the preconstruction stage can help concrete contractors quickly quarantine and resolve issues, including beam interferences, unknown penetrations, and embedded elements, before site work starts. Interference resolution done correctly in Navisworks reduces RFIs and rework that causes project delays.

-

Cut onsite rework for concrete formwork, reinforcement, or embedment

Coordinated 3D models can help contractors realize precise planning for formwork, rebars, sleeves, and embeds. Resource waste and material loss can be prevented by calculating accurate material pours. Swift changes in the 3D precast model ensure there are fewer on-site modifications and much faster structural installation.

-

Prevent the onset of project risks and liabilities

Eliminating ambiguities before they are detected onsite can reduce installation problems, enhance work safety, and cut disputes. A clash-free precast or formwork model can support concrete contractors and manufacturers with precise and complete extraction of documents, including BOQs, BOMs, BBS, prefabrication drawings, GA drawings, and other significant deliverables.

5. Enhance site coordination and communication

Improving site communication and coordination ensures every team works from a centralized repository. Using visual clarity and shared precast models, disciplines can prevent conflicts and align with project requirements.

-

Use a centralized precast model to improve trade collaboration and realize on-site safety

A shared precast 3D model supports every discipline in understanding lifting zones, sequencing, and installation tolerances. It enhances team collaboration, removes clashes between various MEP systems, and clears site ambiguities. This ensures safer work sites and swift installations with reduced field problems.

-

Provide real-time access to on-site teams with updated precast models

Providing on-site crews with real-time access to the precast model ensures every participant aligns with project needs. The provision of real-time updates reduces miscommunication, wipes out the use of outdated drawings, and encourages accelerated installation by aligning crews, schedules, and equipment for higher project efficiency.

-

Achieve stakeholder transparency with structural precast modeling services

Structural precast modeling services support concrete contractors with visual references. Communication transparency using accurate 3D models creates trust, clarifies design intent, and reduces unknown surprises.

Real-world case-studies exhibiting the positive impact of BIM services for concrete contractors

A 3D model at LOD 450 for a residential project in the UAE saves costs on concrete casting members

A precast manufacturer/contractor based in the UAE and India approached HitechDigital for 3D BIM modeling and Rebar shop drawings. With client inputs, the team created a 5 mm coordinated and clash-free 3D BIM model with accurate element fabrication and installation. The 3D BIM model was accompanied by accurate BBS detailing and scheduling, bending, and angles with images.

Handing over the deliverables to the client led to:

- Creation of 3D models enriched with clash coordination under 5 mm for M60 concrete grade

- Swift TAT with 100% accuracy, ensuring cost and time savings

- Improvements in production quality with the precise BIM-driven precast shop drawings

- Faster and more accurate erection with unique structural element IDs

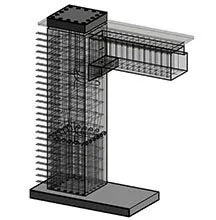

Column Beam Slab Junction

Column Beam Slab Junction

Column Beam Junction

Column Beam Junction

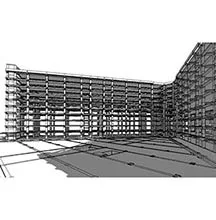

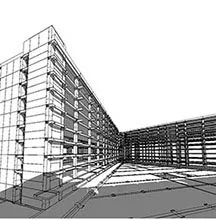

Building External View

Building External View

Building Image

Building Image

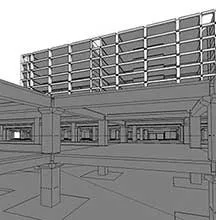

Building Internal View

Building Internal View

Staircase Reinforcement

Staircase Reinforcement

The use of BIM processes and tools in concrete projects enriched with evolving technologies

Using advanced tools like AI and ML, and incorporating accurate concrete mixes has extended the capabilities of BIM for concrete contractors. It has driven better planning, lower carbon emissions, and expedited projects on the site.

The impact of integrating AI and ML in BIM workflows for predictive analytics in concrete projects

Analysis of historical project data using AI and ML algorithms based on patterns can provide deeper insight into material behavior, curing timelines, and the impact of external weather conditions on the project. This supports concrete contractors’ forecasts better and prevents project failures. With AI and ML tools providing advanced capabilities, advanced schedule modifications and faster decision making can be achieved that ensures a risk-free project.

Incorporating optimized concrete mixes to lower carbon footprints

BIM tools like Revit and other automation tools can help evaluate structural load needs and integrate large material databases to simulate and test concrete alternatives. This supports engineers in selecting the right mix with supplementary materials to lower the cement content. An accurate material mix lowers the chances of dangerous material emissions while keeping performance and strength intact.

Conclusion

For concrete contractors, BIM services are a solid lifeline, and a key contributor to protecting profit margins. In a contractor-centric marketplace, owners and general contractors also have to shoulder BIM compliance. That’s the reason it is crucial to adopt BIM practices and tools, and advanced technology for higher reliability and scalability of operations.

When the stakes are high, as in the construction industry, outsourcing BIM services for concrete contractors to a capable BIM partner can also be a smart move. A majority of concrete contractors have already adopted the practice and are reaping benefits.