- Leveraging outsourcing for sheet metal CAD drafting enhances project precision and efficiency.

- Evaluating potential partners on experience, technological capabilities, and scalability is crucial for successful CAD outsourcing in sheet metal fabrication.

- An outsourcing partnership, grounded in trust and credibility, hinges on the pillars of data security and proactive communication.

Outsourcing is a great solution for sheet metal contracting companies dealing with design complexities and tight deadlines. However, choosing the right CAD drafting and modeling outsourcing provider requires careful evaluation of expertise, technological proficiency, cost-effectiveness, and data security.

Table of Contents

- Challenges faced by sheet metal contractors

- Top 10 Factors to consider when choosing your Outsourcing partner for CAD Drafting and Modeling

- Experience and Area of Expertise

- Proficiency in CAD Tools and their Versions

- Support for Custom and Specific Intermediate Stage Drawings

- Flexibility and Scalability

- Process Automation in CAD Drafting and Documentation

- Data Security and Confidentiality

- Engagement Models and Cost-Quality Balance

- Process for client onboarding and project management

- Employee Practices: Stability and Accountability

- Proactive Communication on Potential Delays and Trouble Spots

- Conclusion

Sheet metal contractors often struggle with the dual pressures of maintaining quality while adhering to stringent timelines. This balancing act, amid the scarcity of skilled drafters and fluctuating project demands, becomes precarious to maintain as projects become bigger and more complex.

In this environment, CAD drafting outsourcing opens the doors to expert drafters and modelers who can help meet quality benchmarks and beat deadlines. Sheet metal contracting companies also benefit from the better agility and accuracy that come with the streamlined operations of specialized CAD drafters and modelers. This guarantees quicker project turnarounds.

However, it is extremely important to find the right CAD drafting and modeling company to outsource your work. You need to weigh your specific challenges and find a match with your company culture and workflows. And the outsourcing company has to deliver on its promises of expertise, infrastructure support and responsiveness.

This is why we have highlighted in this article what sheet metal contractors should look for when selecting a service provider.

Challenges faced by sheet metal contractors

Sheet metal contractors often encounter a spectrum of challenges that can impede their progress and impact their bottom line.

Design and work challenges may include inaccuracy, delays in turnaround time, complex design revisions, shortage of skilled drafters, escalating costs, inconsistent workloads, keeping up with technology, maintaining quality benchmarks, inability to balance core and non-core activities, data security and IP rights.

Addressing these challenges requires leveraging the expertise of seasoned professionals in the field of CAD drafting outsourcing. And to deal with them, the rule of thumb is to prioritize resolving those challenges and offload the work than can be safely outsourced.

10 Factors for choosing outsourcing partner for CAD Drafting

1. Experience and Area of Expertise

Why It Matters: The experience of your outsourcing partner is essential for offering sheet metal CAD services. This expertise becomes particularly significant when dealing with varied products, such as structural products, building products, architectural ornamental products, and electrical enclosures. Each of these products has its own set of complexities and requires a deep understanding of sheet metal design and fabrication processes. An experienced vendor brings a wealth of knowledge, having navigated similar challenges and delivered successful outcomes.

Key Questions: When evaluating a potential partner for CAD drafting for contractors, check out their history and ask some relevant questions:

- How many years have they been in the industry?

- What kinds of projects have they handled, especially in the realm of sheet metal design outsourcing?

- Do they have case studies or examples of past projects that align with your specific needs, like shelter structures or electrical enclosures?

Understanding their experience in handling domain-specific challenges will give you a clearer picture of their capability to manage your project’s unique requirements.

Real-World Impact: Imagine a scenario in which a sheet metal contractor needs detailed CAD models for a complex shelter structure. An outsourcing partner with extensive experience in this area can foresee potential design challenges and proactively address them, thereby ensuring a smoother workflow and a more accurate final product.

For instance, their prior experience with similar structures could mean they’re adept at optimizing designs for both durability and cost effectiveness, a crucial aspect in sheet metal fabrication outsourcing. Such practical expertise can be the difference between a project that meets all technical specifications and deadlines and one that faces setbacks and revisions.

2. Proficiency in CAD Tools and their Versions

Why It Matters: Proficiency in a wide range of CAD tools and their latest versions is essential for sheet metal CAD services. Mastery of industry-standard software like AutoCAD, SolidWorks, CREO, and Autodesk Inventor ensures compatibility with various project demands and facilitates compliance with industry standards. These tools offer specific functionalities tailored for intricate sheet metal design and fabrication, enabling precision and efficiency. Alongside this, effective redline management using tools like Bluebeam for PDF markups is crucial for incorporating revisions and feedback accurately. This comprehensive proficiency ensures that every aspect of modeling, from initial design to final revisions, meets the highest standards of accuracy and efficiency, essential in complex projects.

Key Questions: To evaluate a potential outsourcing partner’s capabilities, ask:

- Which CAD tools are they proficient in, and how regularly do they update to the latest versions?

- Can they handle the technical specifications required for mass production or complex custom projects?

- How do they manage design revisions and feedback using redline tools like Bluebeam?

Technology Impact: In a project involving the conversion of Revit BIM data to Inventor CAD files for a significant architectural project, the outsourcing team’s expertise in various CAD tools was crucial. They efficiently managed complex design data, ensuring accuracy and compliance with the project’s technical requirements. Additionally, their skilled use of redline management tools enabled seamless integration of feedback and revisions, enhancing the project’s overall quality. This multifaceted expertise in CAD tools and redline management led to a 30% reduction in delivery timelines, 100% accuracy in outputs, and significant cost savings, showcasing the vital role of comprehensive tool proficiency in CAD services.

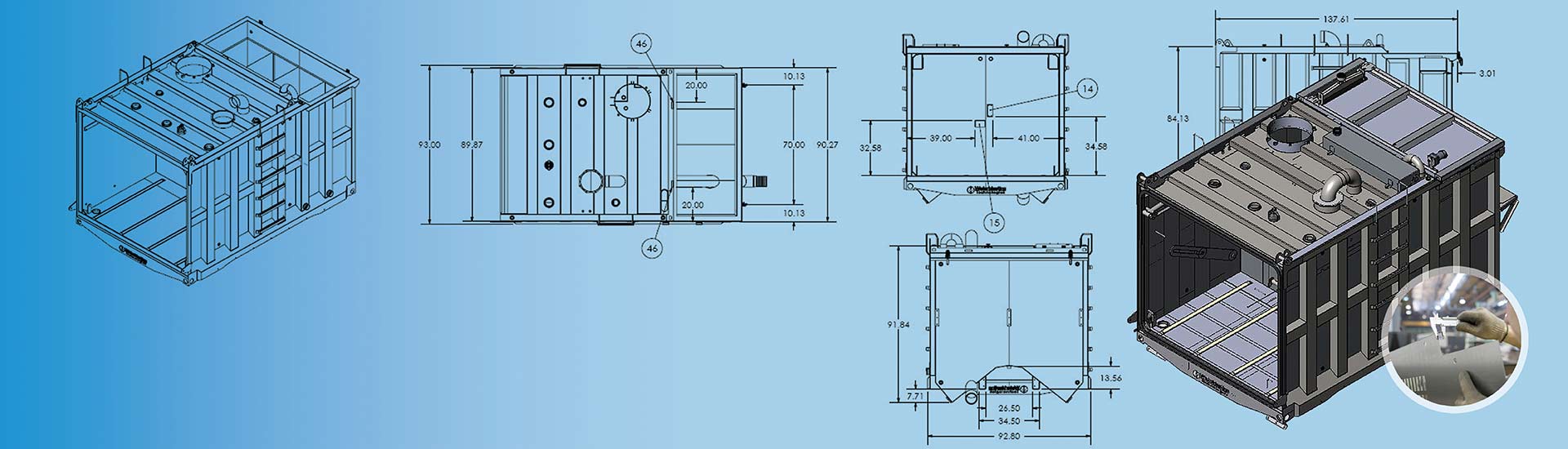

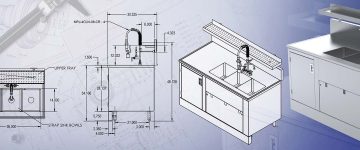

3. Support for Custom and Specific Intermediate Stage Drawings

Why It Matters: The ability to provide custom and specific intermediate stage drawings, such as assembly drawings, part drawings, detailed Bills of Materials (BOMs), isometric, and exploded isometric views, is essential to sheet metal CAD services. These customizations ensure the final product aligns perfectly with the client’s specifications and functional requirements. In the arena of sheet metal design outsourcing, the nuances of each component, connection and assembly can significantly impact the overall project. Custom drawings, especially when they include comprehensive details like BOMs and isometric views, provide a clearer, more detailed roadmap for production and assembly, reducing the likelihood of errors and misinterpretations.

Key Questions: When assessing a potential vendor for CAD drafting outsourcing, it’s important to inquire about their capability to produce custom and specific intermediate drawings tailored to your project’s needs.

- Can they generate detailed assembly drawings that align with your fabrication process?

- How do they ensure that part drawings are compatible with your manufacturing tools and machinery?

- Do they have experience in creating detailed BOMs and isometric and exploded isometric views that offer a clear understanding of each component and its placement?

Impact Assessment: A Russian manufacturer of large-sized steel structures required the conversion of 2D PDF drawings and BoMs into comprehensive 3D models and assembly and part drawings. The team at HitechDigital began by meticulously extracting the necessary information from the input drawings. They then developed initial 3D part models and final steel structure assemblies, following a bottom-up approach to modeling that allowed for easy modifications. This approach enabled them to deliver an average monthly volume of four structures, with approximately 1500 drawings for each, reducing 3D CAD modeling time. This case exemplifies the significance of custom and intermediate stage drawing support in streamlining metal fabrication processes.

How AI is impacting design development for sheet metal fabrication

- Optimize CAD design process with AI for metal fabrication

- Accelerate prototyping; ensure quality and compliance with AI

- Reduce scrap and minimize environmental footprint

4. Flexibility and Scalability

Why It Matters: When opting for sheet metal fabrication outsourcing, companies expect the vendors to be flexible and scalable, as a priority. The sheet metal industry is known for its fluctuating demands and rapid changes in project scope, making adaptability a key factor for success. This need for flexibility extends to every aspect of the project, from the initial design phase to final delivery. It’s crucial for outsourcing partners to be able to scale their resources up or down in response to your project’s changing needs, ensuring that you’re neither overburdened with excess capacity nor under-resourced at critical times.

Key Questions: When evaluating potential partners for CAD modeling for contractors, it’s important to question their ability to adapt to changing project requirements.

- How do they handle sudden increases or decreases in work volume?

- What is the process for managing change orders or design alterations?

- Can they quickly scale their teams in response to an unexpected surge in demand?

Understanding their change management processes and scalability options will give you insights into their capacity to meet your project’s evolving needs.

Scalability Success: Imagine a scenario in which a sheet metal contractor is working on a large-scale commercial building project. Initially, the project scope involved designing standard HVAC components. However, as the project progresses, the client decides to add custom-designed metal facades to the building, significantly increasing the project’s complexity and scale. An outsourcing partner demonstrating flexibility and scalability could quickly respond to this change by scaling up their team, bringing in additional experts in custom metal facade design, and reallocating resources to meet new demands. This adaptability ensures that the project stays on track despite the significant scope change.

5. Process Automation in CAD Drafting and Documentation

Why It Matters: Process automation in CAD drafting and modeling plays a critical role in enhancing efficiency and reducing time spent on repetitive tasks. Design automation tools like DriveWorks and CAD macros and plugins, automates design drafting process as well as documentation for sales and engineering for error-free operations. This not only accelerates project timelines but also ensures consistent quality across all outputs.

Key Questions: When assessing an outsourcing partner’s automation capabilities, inquire along the following lines:

- How do you integrate automation in your CAD drafting and modeling processes?

- What are the specific tools and technologies you use for process automation?

- Share examples of how automation has improved documentation efficiency and accuracy in previous projects.

Automation Impact: For example, in a project focused on designing custom sheet metal components, the implementation of automation tools allowed for the rapid and precise generation of standard component designs. This freed up the design team to concentrate on more complex and custom aspects of the project. The automation of detailed manufacturing drawings and BOMs significantly reduced human error, leading to a more efficient fabrication process. Such strategic use of automation platform provided a high level of precision and reliability in the project’s outputs.

6. Data Security and Confidentiality

Why It Matters: Before opting for sheet metal design outsourcing, the security and confidentiality of project data are paramount. Protecting sensitive project information is crucial not only to maintain the integrity of engineering designs, but also to safeguard the intellectual property of the client. In an age where digital information can be vulnerable to unauthorized access and cyber threats, robust data security measures are essential to ensure that all design details, technical specifications, and proprietary data remain confidential.

Key Questions: When evaluating a potential outsourcing partner, it’s important to thoroughly investigate their data protection measures and confidentiality protocols.

- What are their policies regarding data encryption, access control and secure data transfer?

- Do they conduct regular security audits? How do they handle and store sensitive project data?

- What would you do in case of a data breach, and what will be your response time?

- What measures are in place to mitigate damage?

Data Security Example: An illustrative scenario demonstrating the importance of data security can be drawn from a project involving the development of a new, innovative sheet metal product. The outsourcing partner implements stringent data security measures, including encrypted data transfers, secure cloud storage with limited access, and regular system audits. Robust security protocols ensured that cyber threats were detected and thwarted, with no compromise of data. This factor protects the client’s intellectual property and ensures that the integrity of the project is maintained.

7. Engagement Models and Cost-Quality Balance

Why It Matters: Achieving a balance between cost-effectiveness and quality is essential in sheet metal fabrication outsourcing. Different engagement models, such as Full-Time Equivalent (FTE), hourly, or Build-Transfer-Operate (BTO), have a significant impact on pricing structures. These models determine the flexibility, scalability, and resource allocation, directly influencing the overall cost and quality of the project. It’s crucial to understand how these models align with the project’s budget and quality requirements to ensure competitive pricing without compromising the precision and accuracy necessary in sheet metal fabrication.

Key Questions: When evaluating outsourcing partners, consider their pricing structures:

- Are there hidden costs or additional fees in their pricing model?

- How do different engagement models like FTE, hourly, and BTO affect the pricing and quality of a project?

- What are the cost benefits of each model for your specific project type?

- Can they provide a detailed cost breakdown for each engagement model?

Cost-Quality Balance: In a case involving the design and fabrication of custom HVAC components, the contractor’s selection of the FTE model was pivotal in achieving cost-effectiveness. This model provided a dedicated team of CAD professionals, ensuring better budget control and consistent quality. Working exclusively on the project, the team had an in-depth understanding and focus. The FTE model balanced cost and quality effectively: the dedicated resources guaranteed high-quality, detailed shop drawings and efficient execution, while the fixed pricing structure provided clear financial predictability and cost savings compared to other models.

8. Process for client onboarding and project management

Why It Matters: The customer journey in CAD drafting and modeling projects, which includes onboarding, quality control (QC), project management, and adherence to deadlines, is critical for success. Effective onboarding is essential for ensuring a smooth transition and alignment with project objectives. Rigorous QC is imperative to uphold high standards of output. Moreover, efficient project management is the cornerstone of meeting deadlines and achieving overall project success.

Key Questions: To understand about detailed processes, inquire about:

- The Onboarding Procedure: What specific strategies or processes are implemented to ensure a smooth and efficient start to the project?

- Quality Control Measures: Can you detail the steps and procedures in place to maintain and guarantee high-quality outputs throughout the project?

- Project Management Practices: How are deadlines and project milestones managed? What tools or methodologies are employed to ensure timely and successful project completion?

Impact of Effective and seamless Processes: In a project centered on large-scale industrial design, the process adopted by the outsourcing firm played a pivotal role. The onboarding phase was executed efficiently, swiftly aligning the team with the specific requirements of the project. Stringent quality control (QC) protocols were established to ensure precision in every deliverable. Project management was conducted skillfully, characterized by clear communication and strict adherence to deadlines. This led to the successful completion of the project, meeting all client expectations. This comprehensive approach to collaboration not only guaranteed the timely delivery of high-quality work but also cultivated a strong, enduring partnership between the contractor and the outsourcing firm.

9. Employee Practices: Stability and Accountability

Why It Matters: Employee practices, particularly in terms of organizational culture and attrition, play a significant role in the successful execution of CAD drafting and modeling projects. A well-defined organizational culture that values process-oriented systems and a clear hierarchical structure ensures stability and accountability at all levels. Low attrition rates are indicative of a stable workforce, which translates to consistency and reliability in project handling. These factors are crucial for long-term project success, as they ensure continuity, preserve institutional knowledge, and foster a strong sense of responsibility among team members.

Key Questions: When evaluating an outsourcing partner, try understanding their employee practices:

- What is their organizational culture like, and how does it support a process-oriented approach to CAD drafting and modelling?

- How do they maintain low attrition rates, and what strategies do they employ to ensure workforce stability?

- How does their organizational hierarchy function to establish clear lines of accountability and decision-making?

Impact of Employee Practices: An example of effective employee practices can be seen in outsourcing firms that handle large-scale industrial CAD projects. The strong organizational culture of the firms emphasizes a systematic, process-driven approach, with well-defined roles and responsibilities at every level. This culture, coupled with a low attrition rate, ensures that the team working on the project remains consistent throughout, with minimal disruptions. The established hierarchy allowed for clear accountability and streamlined decision-making, which is crucial in handling complex aspects of the project. The project benefits from a high level of expertise, continuity, and a strong sense of ownership, leading to successful and timely completion.

10. Proactive Communication on Potential Delays and Trouble Spots

Why It Matters: Proactive communication is crucial in managing CAD drafting and modeling projects, particularly when they are outsourced. The ability to anticipate and effectively communicate potential delays and trouble spots is key to maintaining project momentum. Regular updates, proactive alerts about potential issues, and clear channels for feedback are essential components of effective communication. This approach not only ensures transparency but also facilitates timely interventions to effectively manage deadlines, preventing minor issues from escalating into major setbacks.

Key Questions: To evaluate an outsourcing partner’s communication strategies, consider the following:

- How do they identify and communicate potential delays or trouble spots in a project? What methods or tools are used to detect and relay these issues?

- What mechanisms are in place for regular updates and feedback? Can these mechanisms be customized to meet specific requirements, such as daily, weekly, or monthly updates?

- How is deadline management handled? What processes or strategies are implemented to ensure timely completion of projects?

Communication Strategy Impact: In a scenario where a contractor was engaged in a complex, phased CAD project, the outsourcing partner implemented a proactive communication protocol. This protocol encompassed not only regular updates but also early warnings about potential delays or challenges. Such an approach facilitated immediate course corrections and the realignment of resources to swiftly address emerging issues. Regular meetings, including onsite visits during critical project phases, were integral to this strategy. These meetings ensured that all stakeholders remained aligned and could collaboratively manage the project timeline. Consequently, despite encountering several potential obstacles, the project was completed successfully within the established timeframe. This outcome underscores the effectiveness of proactive communication in managing deadlines and navigating trouble spots in complex projects.

Conclusion

The landscape of sheet metal fabrication and contracting is characterized by high stakes and a relentless pursuit of precision. Each of the ten factors we’ve explored plays a pivotal role in navigating this landscape effectively.

From the critical need for experience and expertise in specific areas of sheet metal design to the importance of dedicated resources in ensuring focused and quality-driven project execution, these factors collectively form the backbone of successful CAD drafting and modeling outsourcing.

CAD outsourcing in sheet metal fabrication is a strategic decision that extends beyond immediate project requirements. It represents an opportunity to tap into a global pool of expertise, advanced technology and innovative practices. This approach optimizes resources and ensures quicker project turnaround, positioning contractors for long-term success. CAD outsourcing works as a tactical choice toward achieving excellence, innovation, and sustainability in this domain.

Need experts to outsource sheet metal CAD drafting and modeling?

Choose efficiency, flexibility, experience, and reliability every time