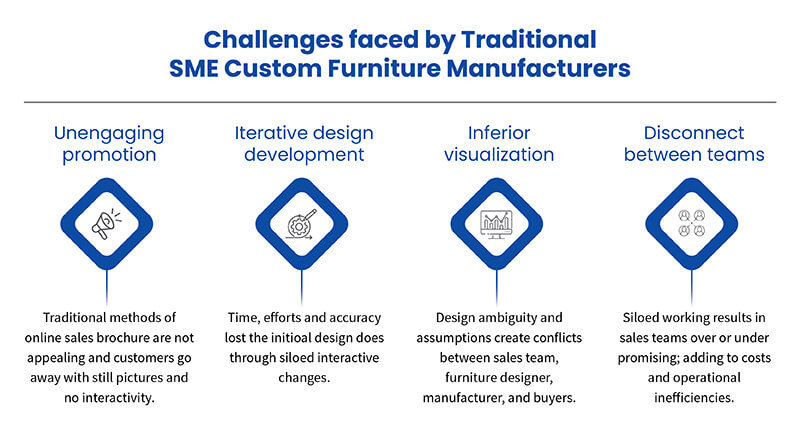

- In a competitive landscape, delivering personalized furniture design with quick turnaround time is the need of the hour for bespoke furniture manufacturers.

- Traditional design development tools fall short in addressing speed, design detailing accuracy and design communication for personalized products.

- DriveWorks automates repetitive design drafting and modeling tasks involved in design personalization. It captures design intelligence and uses logical rules to customize products at accelerated pace.

Custom furniture manufacturers constantly battle to keep the concept-to-manufacturing cycle in sync with market needs like personalized designs, accuracy and speed. To stay on top of competition, they must reduce turnaround time and slips in design detailing.

DriveWorks design automation software helps eliminate iterative design tasks with the highest precision. It is driven by logical rules that help to customize design details quickly by using existing design intelligence. DriveWorks implementation further assists sales reps to streamline the sales process with features like guided selling.

5 benefits of DriveWorks design automation for custom furniture manufacturers

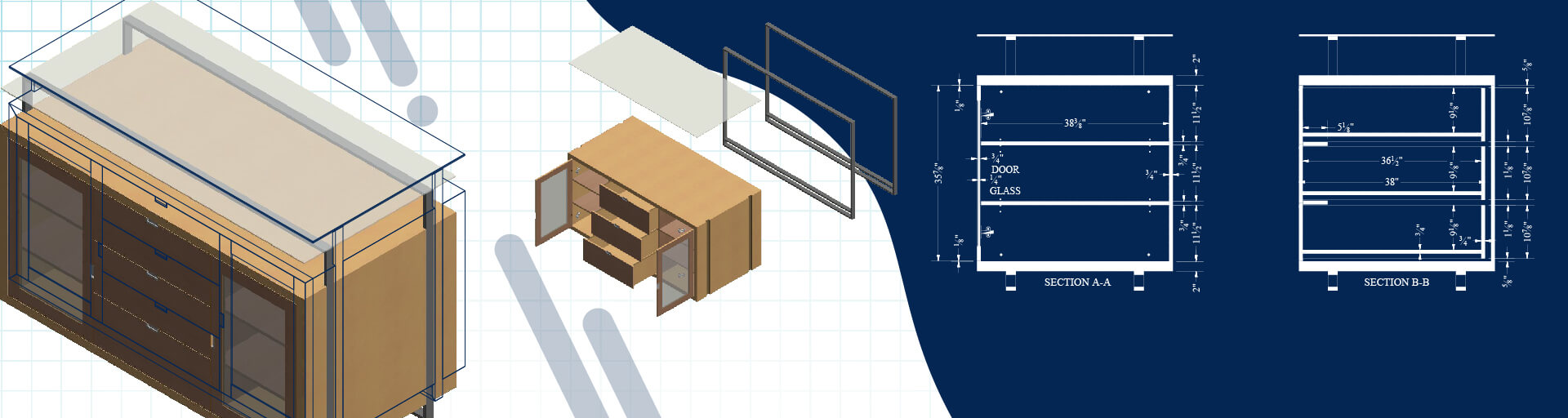

Digital tools like CAD platforms, for example SolidWorks, offer high-end furniture product development in 3D. DriveWorks is a versatile and cost-effective platform for furniture manufacturers helping at every stage, from conceptualization to creation of the final product. Implementing DriveWorks also offers interactive product customization abilities to online buyers, bringing multiple benefits.

1. Provides online real-time digital experience to customers

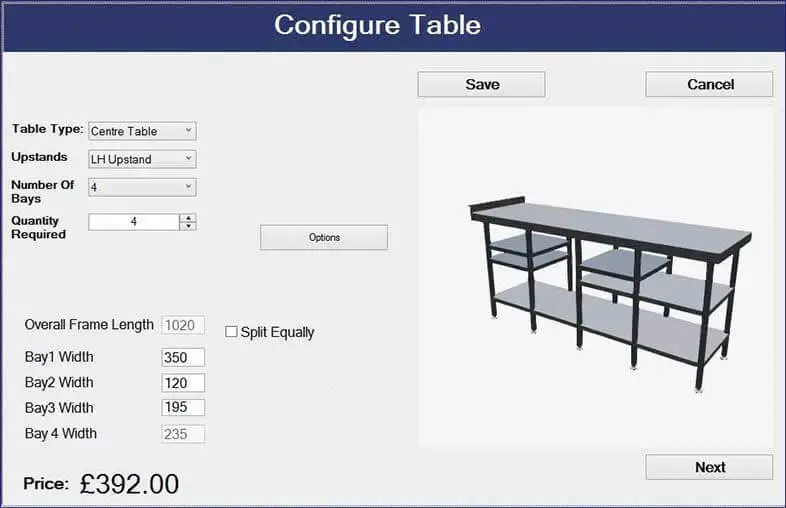

The DriveWorks 3D configurator enables immersive online product configuration of CTO-based custom furniture. Customers can access the online furniture configurator via any device. They can explore and compare material, texture, and feature choices, then select and instantaneously order online. An online product configurator engages them by offering greater control over purchases.

2. Adds in-depth visualization

With 360-degree visualization in the visual configurator, a customer can see the effects of colors, finishes, hardware, shapes, and sizes in the desired environment. Visualization provides ease of choosing different forms and features of materials, shapes, and attachments with rendering. Users can rotate, measure, section, set lightings, and conduct walkthroughs before making any final decision. The advanced use of AR and VR technology now brings real-world visualization along with looks and feels.

Visualization of 3D models helps customers change options of finish, style, and size, along with changes in metal, glass, and wood combinations. It helps in quick decision-making among stakeholders and customers with instant reviews and approvals.

3. Faster concepts and designs

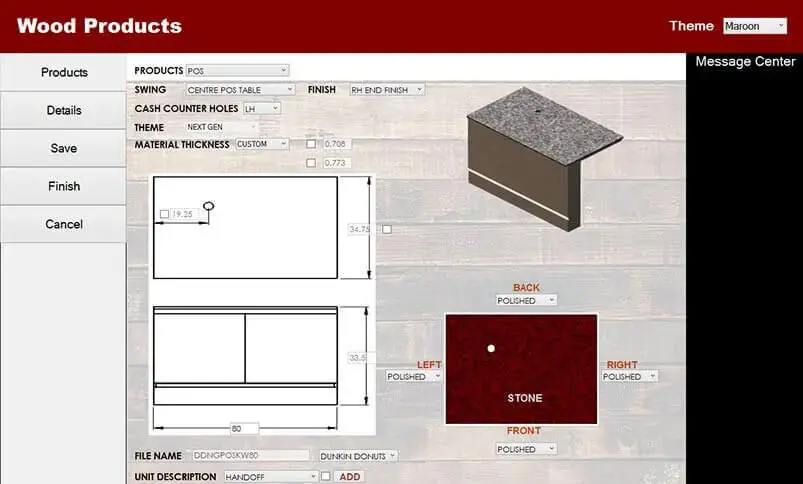

DriveWorks implementation helps to organize custom furniture product offerings better. It creates a master model for configurable product options in the SolidWorks CAD system. And helps to standardize common items like fasteners, wooden sheets, and laminates.

DriveWorks design automation also enables library creation of legacy designs that can be used for new or future requirements and innovations. And it develops templates of standard configurable offerings for the online consumer. With these incorporated, designers can generate concepts rapidly, converting concepts to final designs in hours.

When a customer configures an order online, DriveWorks generates the designs automatically. The user can then add bespoke requirements as per their specifications. This process saves almost 80% to 90% of engineering time spent on configuration.

Finally, DriveWorks reduces the overall lead time of order-to-manufacturing from weeks to within days, or sometimes even in hours. This improves manufacturers’ competence to meet the time to market and achieve higher productivity in sales, design, and manufacturing.

Illustrative case:

CAD Configurator of Wood Products

CAD Configurator of Wood Products

4. Accurate and automated documentation

DriveWorks configurator incorporates various user-friendly templates for quotes, catalogs and process documents. The design engineer can integrate DriveWorks with other business systems like PDM, CAD, ERP, or CRM and can extract in doc, pdf, Excel, or any desired format.

The shop drawings and BOMs are generated automatically and released for the shop floor when the customer confirms the configuration. As there is no human intervention in creating these drawings and documents, they are highly accurate and generated with a few clicks.

All in all, one can configure accurate quotes, generate detailed and precise documents and ensure high quality product manufacturing with the DriveWorks configurator. Designs experience fewer iterations and conflicts, leading to less wastage and better collaboration among stakeholders.

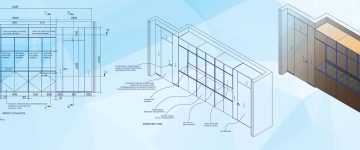

5. Real-time connected and integrated systems

In addition to SolidWorks, DriveWorks connects with all legacy systems through user-friendly APIs. Legacy systems include all value chains in manufacturing, starting from CRM, PLM/PDM, ERP and MES.

As all stakeholders are connected, they can create or view flags for reviews, approvals, and order visibility in real-time and can make informed decisions. At the configuration level itself, one can accurately predict the delivery time with the visibility gained on inventory, production pipelines, and dispatches.

For the direct manufacturing interface, NC programs and DXFs can be generated in an automated way via configurations. These are directly fed to the CNC machine for quick manufacturing and drastically reduce the lead time from design to manufacturing.

Illustrative case:

Online Configurator for SS Furniture

Online Configurator for SS Furniture

Conclusion

To face current market challenges, bespoke furniture manufacturers need to find tools that increase and sustain their market competence. In this, the speed with which they can convert a customer’s requirements to reality plays a big role. Delivering on time with quality demands more agility among the systems and processes in use, from sales to manufacturing. And winning the digital customer demands a higher degree of visualization than offered by traditional tools.

For bespoke furniture manufacturers, CAD automation with DriveWorks and SolidWorks holds the key to driving designers’ efficiency along the value chain. It provides the right mechanism for going online and making furniture products configurable. And real-life visualization for bespoke furniture needs raises the digital buying experience of customers to the next level. Getting business becomes easier.