- 3D CAD modeling for furniture improves precision, customization, and design efficiency.

- It streamlines production workflows through CNC integration, material optimization and virtual prototyping.

- CAD tools support sustainable practices, better stakeholder communication, and faster time to market for competitive advantage.

Table of Contents

Furniture makers struggle with traditional design methods that fail to achieve the precision needed for complex modern designs. Physical prototyping creates material waste and delays and consumes resources. This limits customization and slows down the time-to-market for new products.

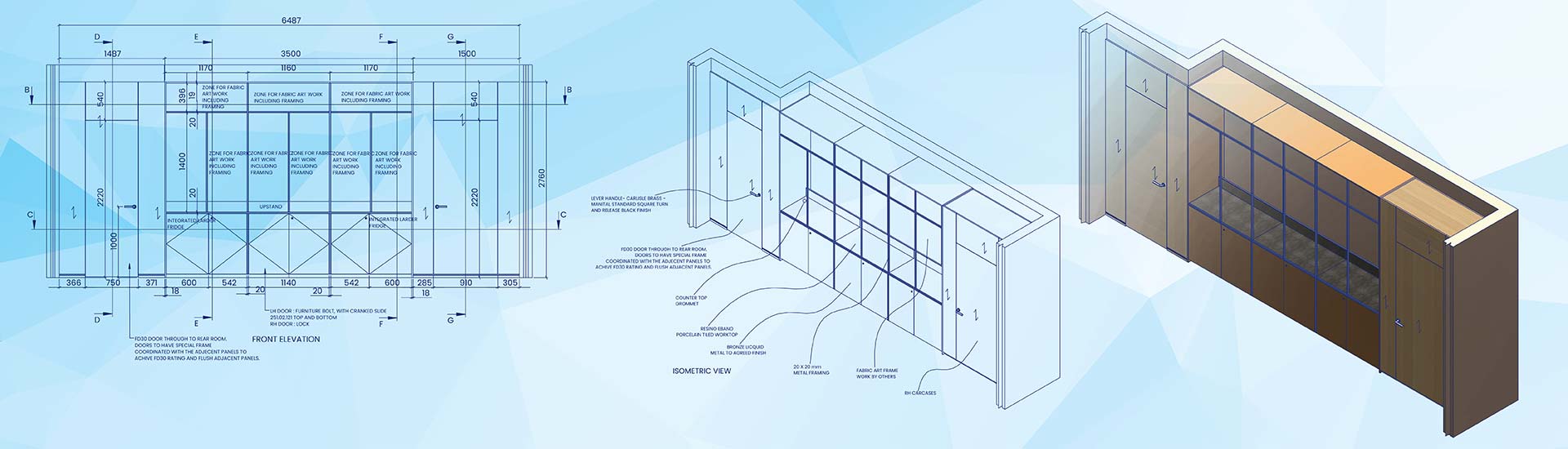

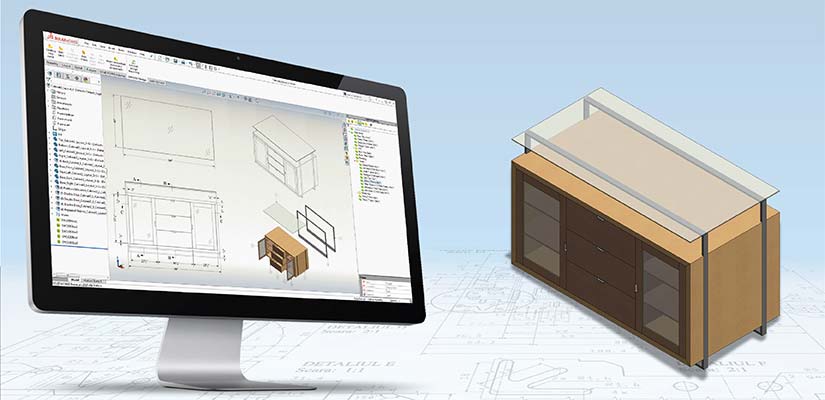

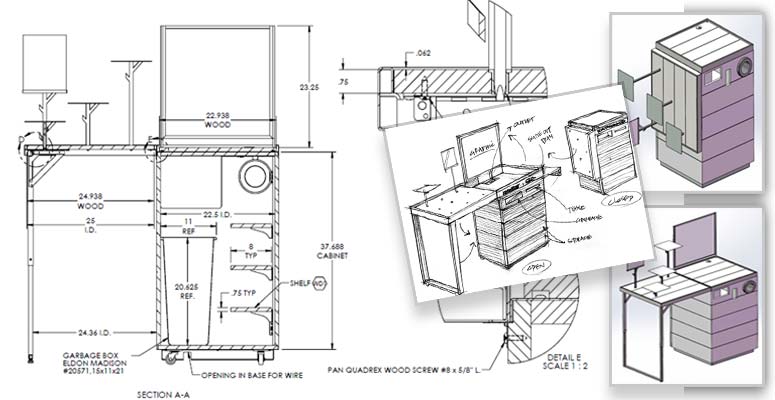

Using 3D CAD modeling for furniture designing helps solve such issues with digital models that serve as accurate blueprints for manufacturing. 3D Furniture CAD design involves virtual prototyping, the generation of detailed component specifications, and fluid integration with production equipment. This establishes a single digital foundation for the entire manufacturing process.

The benefits span across operations: design accuracy, less waste, and less development time. Manufacturers can customize products easily, collaborate with stakeholders, and maintain quality control throughout production. This allows them to meet customer demands faster and stay competitive through operational efficiency.

What are the common challenges in furniture manufacturing

The following are the major challenges that affect furniture manufacturers’ efficiency, quality, and competitive positioning in the market:

- Design complexity and precision requirements: Modern furniture has complex geometries and precise component integration that traditional drafting methods cannot capture accurately, increasing errors in production.

- Visualization and communication gaps: Without unified visualization tools, stakeholders misinterpret design intent and production errors, costly revisions, and customer dissatisfaction follow.

- Prototyping costs and waste management: Physical prototypes require a lot of materials, labor, and time—resources that are strained when multiple design iterations are needed.

- Market demand for customization: Consumers want personalized furniture solutions, but traditional manufacturing methods cannot accommodate customization without a significant cost increase.

- Compressed product development timelines: Intensifying competition requires faster product development while maintaining quality and design integrity.

- Integration of diverse materials: Modern furniture combines multiple materials with different properties and manufacturing complexities that require special consideration during design and production.

3D CAD modeling for furniture solves these challenges by providing a single digital environment where design precision, visualization, efficient prototyping, customization and material optimization come together in one workflow solution.

Visualize furniture concepts with precise 3D CAD furniture models

Transform hand-drawn ideas into detailed 3D virtual prototypes

Top 3D CAD modeling benefits for furniture manufacturing

3D CAD modeling addresses furniture manufacturing challenges, creating new opportunities for innovation and efficiency. These benefits work together to transform how furniture is designed, made and brought to market.

How 3D CAD improves furniture design and prototyping efficiency

Furniture CAD design tools help increase precision, speed up prototyping, enable innovation, and allow complex customizations.

Improved design precision and accuracy

When designing pieces with complicated or curved surfaces, complex joinery, or decorative elements, 3D CAD modeling for furniture allows designers to define exact measurements to the sub-millimeter.

This precision ensures dimensional accuracy during component integration and assembly, eliminating costly errors that happen when components don’t fit together. CAD modeling in wood furniture design validates geometry early in the cycle.

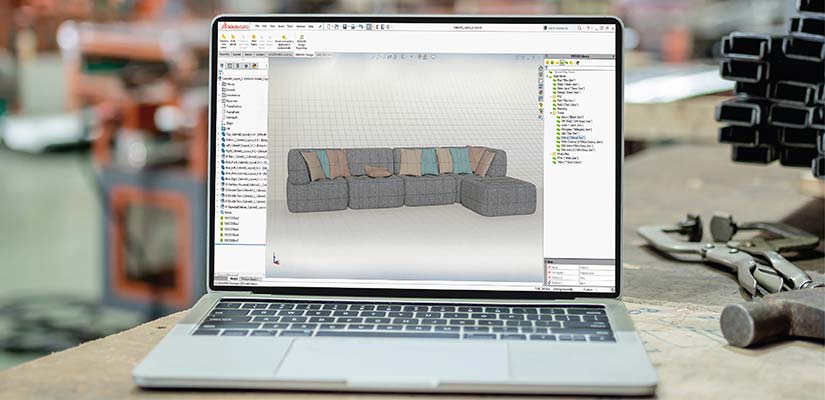

For example, SolidWorks’ advanced 3D modeling techniques are used to model complex cabinet joinery with high curvature detailing, ensuring accuracy in component interfaces and fitment before cutting begins.

Streamlined and cost-effective virtual prototyping

Digital models speed up the design iteration process. Designers can make changes, try different approaches, and refine concepts without the time and material investment required for physical prototypes.

This virtual approach reduces development costs and shortens the design phase by weeks or months. Photorealistic rendering for furniture adds another layer of validation by allowing visual reviews before prototyping.

Facilitating design innovation and exploration

CAD systems allow complex geometries and organic shapes that are impossible or hard to achieve with traditional methods. Parametric design enables furniture designers to try many design variations by adjusting key parameters and seeing results instantly. This freedom to experiment leads to more innovative products and unique design solutions while maintaining manufacturability.

For example, Autodesk Inventor’s parametric modeling allows rapid exploration of furniture structures, and real-time updates to curves and load-bearing joints based on customer feedback.

Enabling scalable customization and product personalization

With custom furniture modeling tools, manufacturers can adapt standard designs to individual customer requirements without extensive redesign work. This allows companies to offer mass customization, enabling personalized products at near mass production efficiency.

Parameter-driven models allow manufacturers to generate variations quickly while maintaining design integrity and manufacturability. CAD customization of modular furniture simplifies these changes through reusable design logic.

Enhanced manufacturing integration and efficiency

3D CAD modeling connects design and production, creating a digital workflow that optimizes manufacturing and reduces errors and resource usage across the production floor.

Seamless integration with CNC machinery

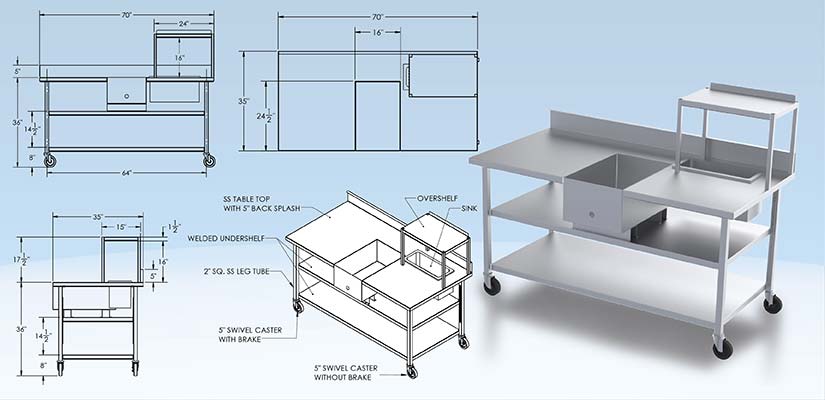

Furniture CAD design can be translated directly into machine code for automated manufacturing systems, eliminating manual programming errors. This digital workflow ensures manufactured parts match the designer’s intent.

Modern CAD software also supports G-code generation for machine capabilities. AutoCAD is used to generate 2D cutting paths for MDF or plywood panels, which are then fed to CNC routers.

For manufacturers using CNC routers and other automated equipment, this integration eliminates data translation errors and ensures precision fabrication.

Material optimization and waste reduction

Advanced 3D CAD systems provide material quantification and automated Bill of Materials, eliminating estimation errors and ensuring the right amount of material is ordered. Advanced nesting algorithms optimize cutting layouts, maximize yield, and minimize offcuts.

Assembly planning and instruction generation

From the 3D model, manufacturers can create clear and visual assembly sequences that reduce ambiguity and errors. These digital assembly instructions include exploded views and step-by-step guidance to improve worker productivity and reduce training time for new employees.

Generating assembly documentation directly from the design model also ensures design intent and production are consistent.

Better quality control and inspection

Quality assurance teams use data from the original 3D model for dimensional checks and verification at various production stages. Some manufacturers integrate their CAD systems with automated inspection technologies, comparing scanned parts to the original design model to find deviations.

This data-driven approach to quality control reduces defects, minimizes rework and ensures consistent product quality.

Sustainable furniture manufacturing using 3D CAD

3D CAD modeling allows manufacturers to be environmentally responsible throughout the product lifecycle, from concept to production and beyond to end of life.

- Design for material efficiency and reduced environmental impact: CAD modeling benefits include designing to minimize material usage without compromising structural integrity or aesthetics. Designers can analyze components to find material reduction opportunities while maintaining strength and selecting sustainable materials based on performance.

- Design for disassembly and circular economy: Through 3D CAD, furniture manufacturers can adopt modular approaches for easy repair, component replacement and recycling. These design strategies extend product life and allow for more efficient material recovery at the end of life.

- Reducing physical waste: By identifying and resolving design issues virtually, companies avoid material waste from failed prototypes and production errors, reducing the environmental footprint of the development process.

- Generating digital twins for lifecycle analysis: 3D CAD models are a complete digital replica, allowing simulation and analysis throughout—from material extraction to disposal or recycling—helping manufacturers identify and address environmental hotspots.

Improved communication between stakeholders

Communication among designers, manufacturers, suppliers, clients, and retailers is key to successful furniture production and 3D CAD modeling makes this communication better.

By providing a shared visual understanding of design intent through photorealistic rendering for furniture, all stakeholders can see the final product with clarity before production starts, reducing misinterpretations and ensuring everyone is on the same page. The technology allows for clear and efficient feedback loops in which stakeholders can input specific parts of the digital model, streamlining design iterations.

High-quality visualizations from 3D CAD drafting services allow manufacturers to show designs in different environments and materials without physical samples, while furniture layout planning with CAD allows virtual room setups where multiple pieces can be placed together.

Interactive product configurators based on parametric models bridge the gap between custom furniture modeling and customer expectations, allowing clients to customize products and see results instantly. This communication extends to suppliers through clear design specifications and streamlined procurement processes, so the right materials get to the right place at the right time and strengthen supply chain relationships.

CAD conversion for retail display furniture manufacturer

A retail furniture manufacturer was struggling to turn handmade concept sketches into detailed manufacturing drawings. Design changes were frequent, mall floor space was limited, which increased the risk of errors and delays, and they needed sustainable, versatile designs.

HitechDigital’s team converted conceptual sketches into 3D models and 2D manufacturing drawings using SolidWorks. They added material specifications, generated BOMs and completed the job in 72 hours ensuring alignment with manufacturing standards.

The final deliverables led to:

- 50% reduction in manufacturing time and cost

- A reusable furniture model library

- Improved design-to-production workflow

What drives furniture manufacturers to adopt 3D CAD modeling

Beyond technical capabilities, 3D CAD for woodworking brings significant business benefits that impact profitability, market position, and customer satisfaction for furniture manufacturers of all sizes.

Accurate cost estimation and project timelines

By using 3D CAD modeling data, companies can generate material requirements, including exact volumes and dimensions for all components. This eliminates the common problems of overordering (which ties up capital) or underordering (which causes production delays).

The manufacturing information derived from 3D models also allows for accurate time estimation for each production phase, from cutting and machining to assembly and finishing.

The improved quoting accuracy from CAD-based estimation helps manufacturers maintain healthy margins while staying competitive on price. Manufacturers using 3D CAD for estimation typically see significant improvement in budget adherence compared to traditional estimation methods.

Faster time-to-market for new furniture designs

3D furniture modeling services speed up every phase of product development, reducing the time from concept to market-ready products. The integration of design, engineering and manufacturing planning in one 3D environment eliminates many of the traditional handoffs and translations between departments that cause delays.

This acceleration of design, prototyping, and manufacturing cycles gives a competitive advantage. Manufacturers respond faster to trends, seasonal demand, and customer preferences. They can launch new products faster and capture premium prices during the initial market phase. This faster time to market is a strategic advantage that helps them stay relevant in the market and drive revenue growth.

Enhanced product quality and reduced manufacturing errors

CAD furniture design services improve product quality by detecting and solving problems before production starts. In digital models, dimensions, clearances, and tolerances can be checked virtually. As interference detection tools find potential conflicts between components, stress analysis can predict structural performance under different loads.

The reduction in production errors brings lower rework costs, less material waste, and increased production efficiency. Most importantly, the better quality and reliability of the final product means higher customer satisfaction, fewer warranty claims and a stronger brand.

Facilitating customization as a competitive differentiator

Consumer demand for personalized products has turned customization from a niche offering to a mainstream expectation. CAD customization for modular furniture allows manufacturers to meet this demand.

For example, Autodesk Inventor’s iLogic feature automates design configurations for custom modular shelving units, enabling real-time design personalization with minimal manual intervention.

This ability to offer customization without significant cost premiums opens up new markets and increases customer loyalty. This helps manufacturers expand their market beyond standard product lines.

Why is 3D CAD design essential for your furniture clients

3D CAD modeling brings value directly to furniture clients through better decision making and purchase confidence. Here’s how:

- Better product examination and understanding: Interactive 3D models allow clients to see furniture from multiple angles, understand proportions and design details that photos can’t show.

- Real time customization and preview: Clients can modify dimensions, materials, finishes and configurations and see the visual impact instantly. No more guesswork and the final product matches the clients’ expectations accurately.

- Accurate space planning and fit verification: Clients can place furniture in their actual space dimensions to verify fit and style before they buy, reducing the risk of sizing errors and costly returns.

- Better communication with design teams: 3D visualization helps the clients communicate preferences to designers and manufacturers more effectively. This reduces misunderstandings that lead to dissatisfaction with the final product.

- Faster approval and order processing: Digital 3D models enable faster client sign offs and approvals, speeding up the design concept to production phase while ensuring clear documentation of agreed specifications.

Future of 3D CAD modeling for furniture

Cloud-based 3D CAD modeling in wood furniture design is changing the way teams work together on furniture projects. By letting multiple people work on the same model in real-time, these platforms make collaboration much more efficient.

AI also helps optimize furniture designs. Algorithms analyze your designs for structural efficiency, material usage and manufacturing complexity. Trained models spot improvements that might have gone unnoticed by even the most experienced designers—leading to better-performing products with a lower environmental impact.

Generative design algorithms then propose many design alternatives based on what you need and what you want to achieve.

VR and AR visualization using 3D modeling allows customers to see how a piece of furniture would look in their own space before they buy it. This reduces purchase uncertainty and return rates. Digital twins for lifecycle management use 3D models to provide valuable data for maintenance, repair and eventual recycling or disposal of products.

Conclusion

The comprehensive benefits of 3D CAD modeling—design innovation, manufacturing efficiency, stakeholder communication, and business strategy—make it critical for companies of all sizes. Using 3D CAD provides precision design, streamlined prototyping, manufacturing integration, sustainability, and better communication.

For furniture manufacturers navigating the challenges of complex designs, compressed timelines, and customization demands, 3D CAD modeling for furniture provides a strategic foundation for operational excellence. Manufacturers embracing these capabilities can easily overcome traditional challenges of furniture design and production, helping them to achieve a competitive edge in the market.

Speed up design cycles with 3D CAD furniture modeling

Collaborate better with precise digital mockups