Client Profile.

The client is an Asian manufacturer of kraft paper bags, corrugated packaging boxes and other paper-based recycled products of distinct size, thickness, and color.

Business Need.

The kraft recycling plant had permission to use a maximum power load of 840 kVA. Any breach of this limit would invite heavy penalties from the power distribution authorities. However analog meters and manual processes not just inhibited real-time visibility into energy usage, but also threw up inaccurate insights on consumption patterns.

As a result, the plant often ended up having to pay hefty penalties for breaching threshold limits. The inability to control erratic consumption patterns also affected the safety of the main feeder.

The manufacturer commissioned HitechDitigal to digitalize their energy monitoring system to get greater and more accurate visibility and control over energy patterns across the plant.

Challenges.

- The systems at client end were outdated and needed significant upgrade to enable them to be compatible to share data with IIoT gateway.

- The data across the plant was resting in silos and limited a cohesive view of energy information across plant.

- There were no standardized formats for reports which made things unstructured.

Solution.

HitechDigital deployed an intelligent Energy Monitoring System which included smart CTs (current transformers), smart energy meters, IIoT gateway, IIoT platform and cloud services. The solution enabled:

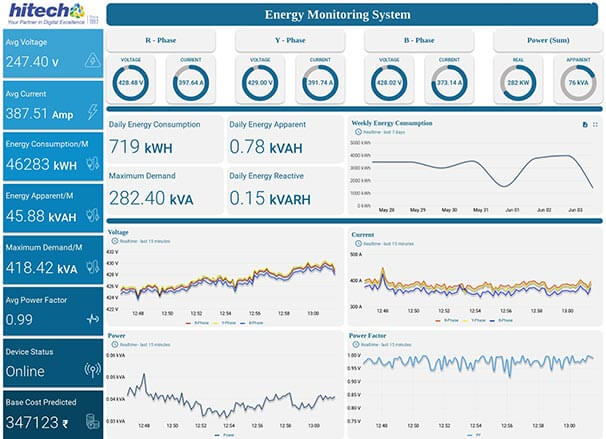

- Real-time visibility of all energy parameters like kWH, kVA (Real power), Power Factor, Maximum Demand, Voltage, Current etc. across the plant.

- Alerts and notifications through instant SMS, email, and web app on violation of pre-defined threshold parameter ranges.

- On-demand reports on energy consumption.

Approach.

Assessment and Documentation:

- An in-person onsite assessment by the HitechDigital experts highlighted the following issues:

- Due to the use of legacy energy meters, there was no established communication protocol between the energy meter and Current Transformer (CT).

- There was no single OT network to connect all the devices in a single network.

- Studied six months’ electricity bills to study the energy patterns of the entire unit and designed report formats accordingly.

- Defined energy KPIs and their benchmarks/ranges.

Deployment of Smart Energy Monitoring System:

- Seven energy meters were installed in the main and sub feeders.

- 21 CTs were installed on busbars.

- IIoT control panel was installed in the main control room.

- A single OT network was established to connect the above devices for real-time monitoring of energy patterns.

- Configured energy benchmarks/ranges on dashboards.

- Logic and mechanism were defined to transfer data from gateway to cloud at defined frequencies.

- Designed multiple web-based intuitive dashboards for real-time visibility into different energy parameters.

- Set up instant alerts and notifications via web app, SMS and emails for various energy parameters and breach of threshold values.

- Enabled on-demand report generation for various energy parameters.

Tools and Technology:

- Cloud, IIoT Platform, IIoT Gateway and Postgre SQL

On Demand Report

On Demand Report

EMS Dashboard

EMS Dashboard

Energy Monitoring System

Energy Monitoring System