A global waste tyre management company involved in the collection and disposal of scrap tyres.

The company was struggling to accommodate a growing demand for scrap tyre collection services in the region, crucial for their expansion plans, while continuing to maintain its reputation in delivering industry-leading pick-up frequency.

The client was using a manual forecasting solution, which had an error rate of +/-50%. And was looking for a solution that could help them forecast tyre volume within +/-10% at individual client level. And connect it with a route optimization tool to be able to serve more clients without an increase in fuel costs.

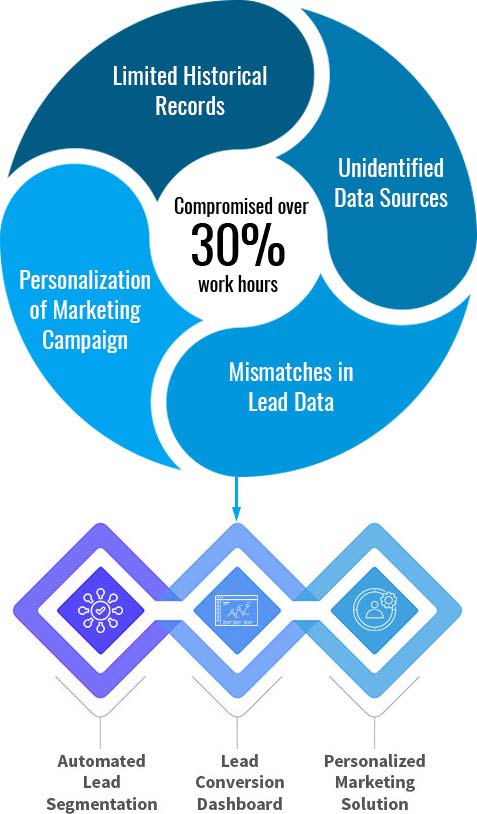

Limited access to historical data: Historical tyre order data available of less than a year as well as large variations in available data

Data silos and quality issues: Gaps in information availability on several parameters such as the truck availability and growth in the service area, competition, customer attrition, etc.

Data preparation issues: Available data was spread across multiple systems using different process / standards for data capture, making consolidation of all the data a tricky task.

Designed Order forecasting and Route optimization solutions, which included

The following steps were taken to address data quality, quantity and consolidation issues:

Selected machine learning / deep learning methodologies using Neural Networks. The solution enables estimating order frequency and volume at individual client level. This involved simulating very large number of iterations (somewhere around 10,000+ models) across different set of advance ML methodologies (Neural Networks) and different parameters to achieve satisfactory level of accuracy (+/- 10% average error).