- Custom architectural component manufacturers often struggle with tight timelines and low buyer engagement leading to customer attrition and negative impact on sales.

- A CPQ delivers an engaging and personalized sales experience through an interactive interface, making it easier for users to learn of choice-related cost/benefits.

- CPQ enhances overall sales process of custom product through guided selling and real-time sales quotes to the customer.

The growing global demand for personalization has architectural component manufacturers juggling with tight delivery schedules, economies of scale, and customization demands.

Even after confirmation, poor design communication and the need to accept last-minute design changes can make things chaotic.

In such a scenario, CPQ backed by design automation, streamlines workflows with end-to-end integrations. CPQ ensures client satisfaction through transparency in choice, expectations and costs from the first step in the sales cycle

From the first sales interaction that the buyer has to the final purchase order, CPQ is reshaping the architectural component manufacturing industry.

CPQ offers customers an option to self-configure designs. This essentially reduces purchaser’s regret and ensures higher revenue.

In this guide, we explore the transformative impact of CPQ for manufacturing, and its pivotal role in elevating customer engagement, sales efficiency, and overall success in a customer-driven market.

Table of Contents

- Challenges faced by custom architectural component manufacturers

- CPQ: Role and significance for architectural component manufacturers

- How a CPQ benefits architectural component manufacturers

- Key features of a CPQ for architectural component manufacturers

- Technologies used in a developing CPQs

- Factors architectural component manufacturers should consider before deploying a sales CPQ

- Top 5 used cases of using a CPQ for ornamental component manufacturing

- Future trends and advancements in CPQs for architectural product manufacturers

- CPQ: Digital transformation in architectural component manufacturing industry

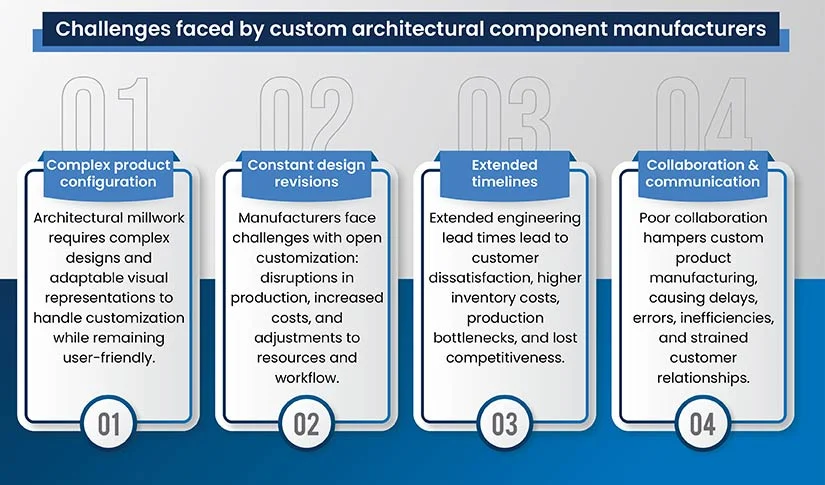

Challenges faced by custom architectural component manufacturers

Given high degree of personalization in the architectural component manufacturing industry, major hurdles that manufacturers face are related to time, iterations, quality and communication. Let’s take a look at these challenges and their impact.

CPQ: Role and significance for architectural component manufacturers

CPQs aid architectural component manufacturers in overcoming the challenges presented by custom manufacturing and sales. They cater to a wide range of products that require extensive customization, such as doors, windows, facades, canopies, railings, and cladding systems, by enabling close collaboration and real-time updates.

Utilizing logical rules and an interactive interface, a CPQ empowers customers to envision and personalize various attributes and functionalities of the products. Additionally, they provide dynamic pricing by instantly recalibrating as customers make changes to their preferred features.

How a CPQ benefits architectural component manufacturers

For architectural component manufacturers, every order is bespoke. Technology platforms like DriveWorks and Autodesk Forge enable creating custom 3D models of products. These platforms enable successful adoption of CPQ for seamless information sharing across all stakeholders.

1. Enhanced customer experience with interactive sales

Allowing customers to customize their purchases not only enhances the user experience but also improves the overall sales process. Using interactive and guided 3D configurations, one can customize even a highly complex product with ease during sales process.

Imagine a customer using an online portal to refresh their windows style and appearance. If the interface shows intricate details of the window such as trims, locks, hinges placement, material, they can make informed decisions.

Such interactive interface eliminates gaps in design communication usually have while buying a customized product. It enables ‘buy what you see’ experience and streamlines the sales process and improves conversions.

2. Real-time visualization

Real-time visualization in a CPQ gives customers a clear visualization of customized products. This dynamic visualization capability helps customers make a better-informed choice. Consequently, errors are reduced and a customer feels more satisfied with the sales experience.

For example, while designing louvers, if customers can see what their product would look like, it can drive better decisions. Detailing like colors, dimensions, look and feel of the overall product can be actually judged better with a rendered 3D visualization.

3. Faster decision-making because of reduced design iterations

Visual configuration capabilities in CPQ uses predefined rules and constraints to ensure compatibility and viability of selected customization options. This system, with its inherent rules, promptly alerts customers about any incompatible selections they might have made in real time.

Simultaneously, it also suggests alternate suitable options. This functionality help identifying potential design challenges at an early stage, minimizing the necessity for multiple iterations, and conserving time. It ultimately ensures the final design of the component aligns accurately with the expected specifications.

4. Increased sales conversion and opportunities for upselling and cross-selling

CPQs can capture a vast array of data including customer preferences, component design choices, and overall sales choices. This information can highlight trends in customer preferences and provide opportunities for upselling and cross-selling in real-time.

The data also gives insights for inventory management based on customization patterns

It drives information on trends and shows peer choices to motivate customers to explore premium features or upgrades that they might not have been considered previously. This is done by integrating intelligent recommendation systems that highlight relevant purchases made by other customers.

5. Increased sales revenue

A CPQ boosts sales by personalizing the shopping experience for each customer. Through login credentials, customers don’t need to configure a product at one go. They can save partial configurations and pick up from where they left the last time during a new session.

Additionally, real-time visualizations of customized products instill confidence and reduce purchase hesitation. Transparent customization builds trust, influencing buying decisions. Fewer returns, due to accurate product expectations, ensure more retained sales. Integrated marketing campaigns spotlighting the CPQ attract more customers. Overall, CPQs transform shopping, driving sales through personalized, interactive experiences.

6. Design validation to speed up sales-to-engineering cycle

A product CPQ facilitates the flow of communication between the sales and engineering teams in several ways. First, it enables the sales team to capture customer requirements efficiently. This captured data is then relayed accurately to the engineering team for further processing, ensuring smooth transitions and enhanced communication.

Secondly, the defined rules for customization in the CPQ guarantee that the configured product model adheres to engineering constraints. This diminishes the need for repeated validation from the engineering team.

Unleash the power of CPQ

Configure your CPQ to completely eliminate sales quote and engineering design hassles.

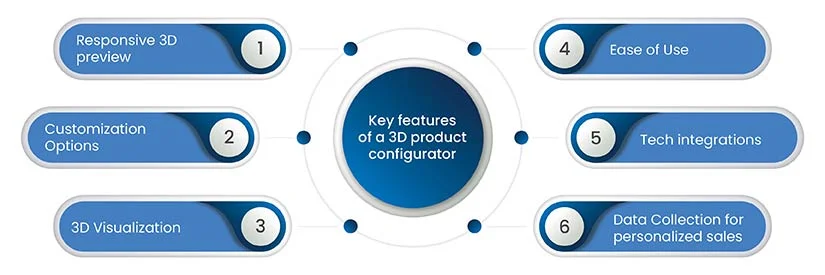

Key features of a CPQ for architectural component manufacturers

1. Responsive 3D preview

Responsiveness is a crucial aspect for software and applications. It guarantees a consistent online experience for customers across various devices. Likewise, a CPQ should support responsive 3D previews of architectural components. It gives the best visuals of designs to the customers.

Whether it’s a laptop, tablet, or a mobile device – the interface should dynamically adjust the 3D preview of the product. Ideally, the preview changes with the change in screen size and aspect ratio. It should also encompass options to showcase the preview and parameters control side by side or stacked vertically. This ensures the customers can comprehensively view and adjust configuration.

2. Customization Options

Customization is the essence of a CPQ. More customization options translates to better customer experience and increased chances of sales. Hence, look for a CPQ that offers extensive component design customization. This may include selection of custom dimensions, finishing, texture, materials, colors, patterns, and more.

Ideally, customization is not limited to the physical appearance of the model. So it becomes inevitable to ensure that the CPQ also has options to incorporate functional customization. This may include ability to select other functional attributes of the product being customized.

3. 3D Visualization

Whether it’s wood, metal, or laminate, the quality of the 3D visualization should be good enough. It accurately depicts the tactile quality of each material being used. To ensure customers can make and visualize personalized selections, the online 3D CPQ should offer quick updates. It should reflect the changes in real-time.

4. Ease of Use

The design interface should be interactive and easy to use to allow your customer to navigate through various features. The choice of design elements, including navigation menus and buttons, should be clearly visible. Hence, it is advisable to choose a CPQ that offers a simple framework.

5. Tech integrations

To make your CPQ fully functional while enhancing the overall experience of the customer, look for the product configuration solutions that offer seamless integrations capability with 3D CAD platforms.

For example, the visual product configuration should support integration with an e-commerce portal so that the customer can easily add the customized product to the cart. Similarly, integration with the pricing systems or databases is essential. It provides customers with accurate pricing information based on the selected customizations.

You can also integrate a CPQ with an existing architectural design software. Ready integrations are generally available for CAD systems like SolidWorks, Inventor, Creo, etc.

Some CPQs also offer ready integration with an Order Management System to automate the order processing for customers. As soon as the customer completes the customization and places an order, the system automatically generates the order. It shares relevant order details with the customer.

6. Data collection for personalized sales

Data collection is a valuable feature in a CPQ for architectural component manufacturers. It allows them to gather important data on component specifications, requirements, design variations, and customer inputs. This data provides key insights into customer preferences and helps identify patterns in their customization choices.

By analyzing the information, manufacturers can optimize the CPQ to enhance the customer experience. The data also enables manufacturers to deeply analyze customer choices and feedback, to offer tailored discounts, offers and services for every customer.

Transform each customer interaction into a unique sales experience

Integrate your CPQ with other business systems and detailed insights into your customers’ shopping choices.

Technologies used in a developing CPQs

1. DriveWorks

DriveWorks is a rule-based design automation software that lets engineers and technical teams build predefined rules and logic. This enables generating design outputs against varied customer inputs. It also enables creation of interactive 3D models with options to select and change component specifications within considerable range.

DriveWorks Xpress module is available as a free add-on in SolidWorks. For full-scale DriveWorks implementation, other licenses for DriveWorks Pro and DriveWorks Live can be purchased from resellers. The engineers associated with resellers rely on key considerations to implement DriveWorks CPQ for you.

2. Inventor iLogic & Forge

Inventor iLogic is a powerful toolset that comes with Autodesk Inventor software. It allows manufacturers to add an additional layer of intelligence to architectural component designs using advanced parameters and equations. This in turn helps create intelligent parametric models that can be customized based on specific design requirements of architectural components, allowing for efficient and accurate customization.

Forge is Autodesk’s cloud-based platform for building custom software applications and workflows that leverage Autodesk’s vast suite of design and engineering tools. In a CPQ, Forge can be used to create a highly interactive, online configuration experience for customers.

With Forge, the user can configure their product in a 3D view, seeing in real-time the effects of their configuration choices. This helps the user (customer, sales team or design engineer) understand and visualize their product before purchasing, which can lead to higher customer satisfaction and increased sales.

Together, iLogic and Forge offer a powerful solution for developing a CPQ. iLogic ensures that the design rules and logic are error-free, while Forge brings those designs to life in a user-friendly and interactive application.

Factors architectural component manufacturers should consider before deploying a sales CPQ

Here are some key ROI considerations one can expect when implementing a sales CPQ in the architectural industry:

1. Improved customer retention

A sales CPQ offers customers a wide range of design customization options through realistic 3D previews and visuals. This immersive experience of personalizing their choices and seeing real-time changes enhances the overall customer experience. By improving customer satisfaction and loyalty, the sales CPQ helps increase customer retention. Loyal customers are more likely to engage in repeat business and refer the brand to others, leading to better long-term profitability.

2. Competitive advantage and market differentiation

Implementing a sales CPQ helps your architectural offerings stand out from competitors. It showcases that you value your customers and are committed to improving the experience they encounter while availing your services. This competitive advantage contributes to a positive ROI by driving business growth and capturing a larger market share.

3. Scalability and adaptability

A sales CPQ is highly flexible and adaptable to meet your specific architectural business requirements and adapt to evolving market trends. Whether it’s about adding new design options or incorporating a new integration technology, the CPQ can easily accommodate updates as your business scales. This flexibility ensures that your business remains agile and responsive to market demands all the time.

Top 5 used cases of using a CPQ for ornamental component manufacturing

While the applications of CPQs span across ornamental component manufacturing, there are key use cases where they have proven to be particularly effective:

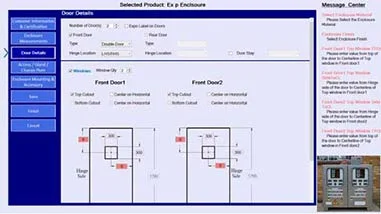

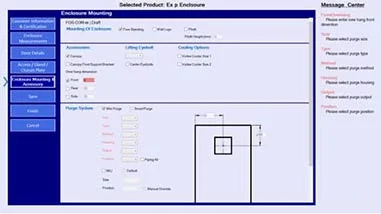

HitechDigital team accelerated creation of multiple designs for electrical enclosures using DriveWorks CPQ

A UK-based explosion protector panel manufacturer was looking for an effective DriveWorks partnership to automate existing electrical junction box design. The designs were originally initiated by another reseller and had multiple roadblocks. HitechDigital’s design automation team took charge by improving the 3D preview model of the product. Furthermore, DriveWorks experts also fixed spacing issues by addressing the disorientation challenges of cable gland plugs.

Business Impact:

- Enhanced overall efficiency of the design and customization process

- Improved accuracy leads to higher-quality enclosures

- Streamlined design validation

Product Configurator for Electrical Enclosures

Product Configurator for Electrical Enclosures

DriveWorks Configurators

DriveWorks Configurators

HitechDigital Team speeds up design cycle time by leveraging DriveWorks CPQ

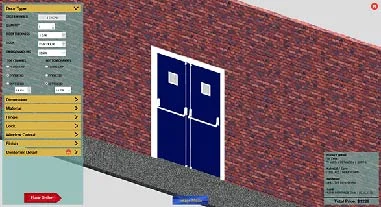

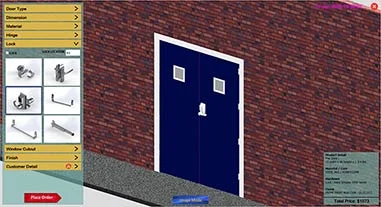

HitechDigital’s DriveWorks experts enabled a US-based manufacturer of hollow metal doors and frames to improve quoting process. The team automated design customization and custom quote generation using DriveWorks door CPQ.

Business Impact:

- Faster response rates

- Reduced capital expenditure with 70,000+ doors designed

- The quality improved by 99%

- Reduced design cycle time by 70%

3D Door Configuration

3D Door Configuration

3D Door Configuration

3D Door Configuration

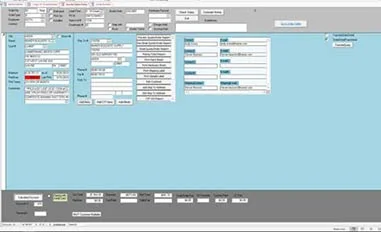

Streamlined shutter configuration using DriveWorks and MS Access

HitechDigital’s DriveWorks experts enabled a US-based manufacturer of hollow metal doors and frames to improve quoting process. The team automated design customization and custom quote generation using DriveWorks door CPQ.

Business Impact:

- Automated sales-to-engineering process for custom windows and louver designs

- Set up auto-mailing system to customer within two seconds of placing the order

- Brought down customer wait time to zero

- Reduced the overall cycle time by 95%

MS Access Database for Sales Process

MS Access Database for Sales Process

DriveWorks Configurators

DriveWorks Configurators

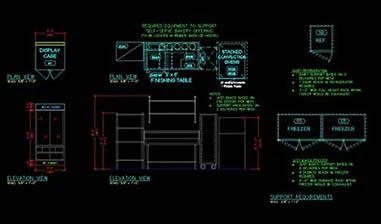

Reduced design errors from 170/month to 18/month for store furniture manufacturer with DriveWorks

HitechDigital’s design automation team leveraged DriveWorks to speed up lengthy design cycles for a store furniture manufacturer. Inaccuracies in flat pattern and AutoCAD manufacturing drawings, as well as customized versions for regular tables. They prioritized DFM and K-factor for sheet metal for developing versatile 3D models in SolidWorks and implemented design automation to automate repetitive design modeling for customization.

Business Impact:

- Reduced error count from 170/month to 18/month

- Reduced material waste and total man-hours

- Furniture designs passed prototype tests by nearly 100%

2D Furniture Drawings

2D Furniture Drawings

2D Drawings for Custom Furniture

2D Drawings for Custom Furniture

Accelerated sales-to-engineering cycle for washroom design from 10-15 days to 3 hours using DriveWorks

A team of design automation engineers collaborated with the client to streamline washroom cubicle design. They developed master models using a generative method, implemented logical rules, and created a robust SQL database. An interactive UI displayed real-time 2D/3D views, while DriveWorks Autopilot generated manufacturing drawings, 3D models, and sales quotes.

Business Impact:

- Faster sales-to-engineering cycle from 10-15 days to 3 hours

- 3D preview of room plan for accurate design customization

- Delivered interactive sales experience

Reuse design intelligence with DriveWorks CPQ

Accelerate complex design development and ensure up to 100% accuracy in sales and manufacturing documents.

Future trends and advancements in CPQs for architectural product manufacturers

Here are some key trends to look out for enhanced customer experience and streamlined design process in CPQs:

1. Augmented Reality (AR)

Integrating AR technology allows architectural product manufacturers to provide virtual views of their components in the customer’s physical space. With AR devices, customers can explore the design specifications, check compatibility, and assess product aesthetics from the comfort of their homes.

2. Virtual Reality (VR)

VR offers a fully immersive experience, enabling customers to interact with and customize virtual component designs. For designers and architects, VR provides an interface for interactive virtual meetings, allowing them to collaborate and review 3D design models in real-time.

3. Mobile app integration and mobile-first approach

Considering the increasing prevalence of mobile devices among end customers, there’s a shift towards mobile app integration and mobile-first app approach in CPQs. Both customers as well as architectural product stakeholders are emphasizing on developing dedicated mobile apps that provide on-the-go access to the CPQ.

4. Voice-activated configurators

Voice-enabled technologies like Alexa and Google voice assistant are gaining popularity across industries, including architectural product manufacturing. Manufacturers are exploring the possibilities of running CPQs through voice commands. Voice-activated configurators enhance accessibility to offer customers a seamless customization experience.

CPQ: Digital transformation in architectural component manufacturing industry

CPQs hold immense potential for furniture manufacturers. With the tool, they can digitally transform the online shopping experience for customers. However, it is equally important choosing the right integration partner for efficient customization, automating the processes, and ensuring accuracy.

Technology partners such as DriveWorks and SolidWorks further assist ornamental product manufacturers in unlocking the full potential of CPQs. This leads to improved operational efficiency, a more personalized customer experience, and a dependable edge in a competitive market.