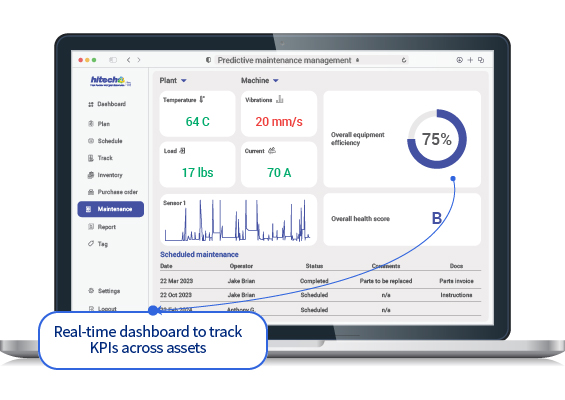

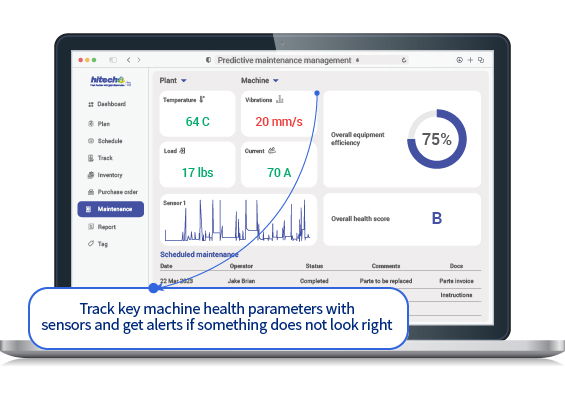

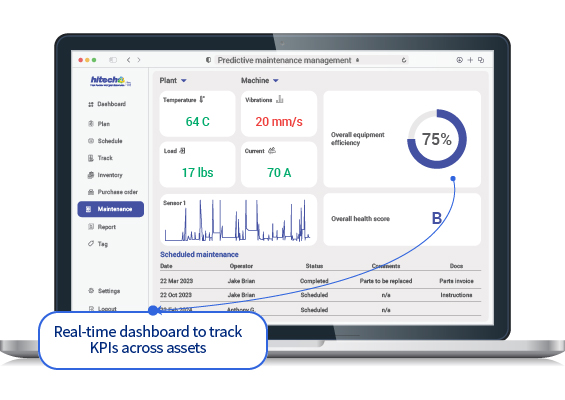

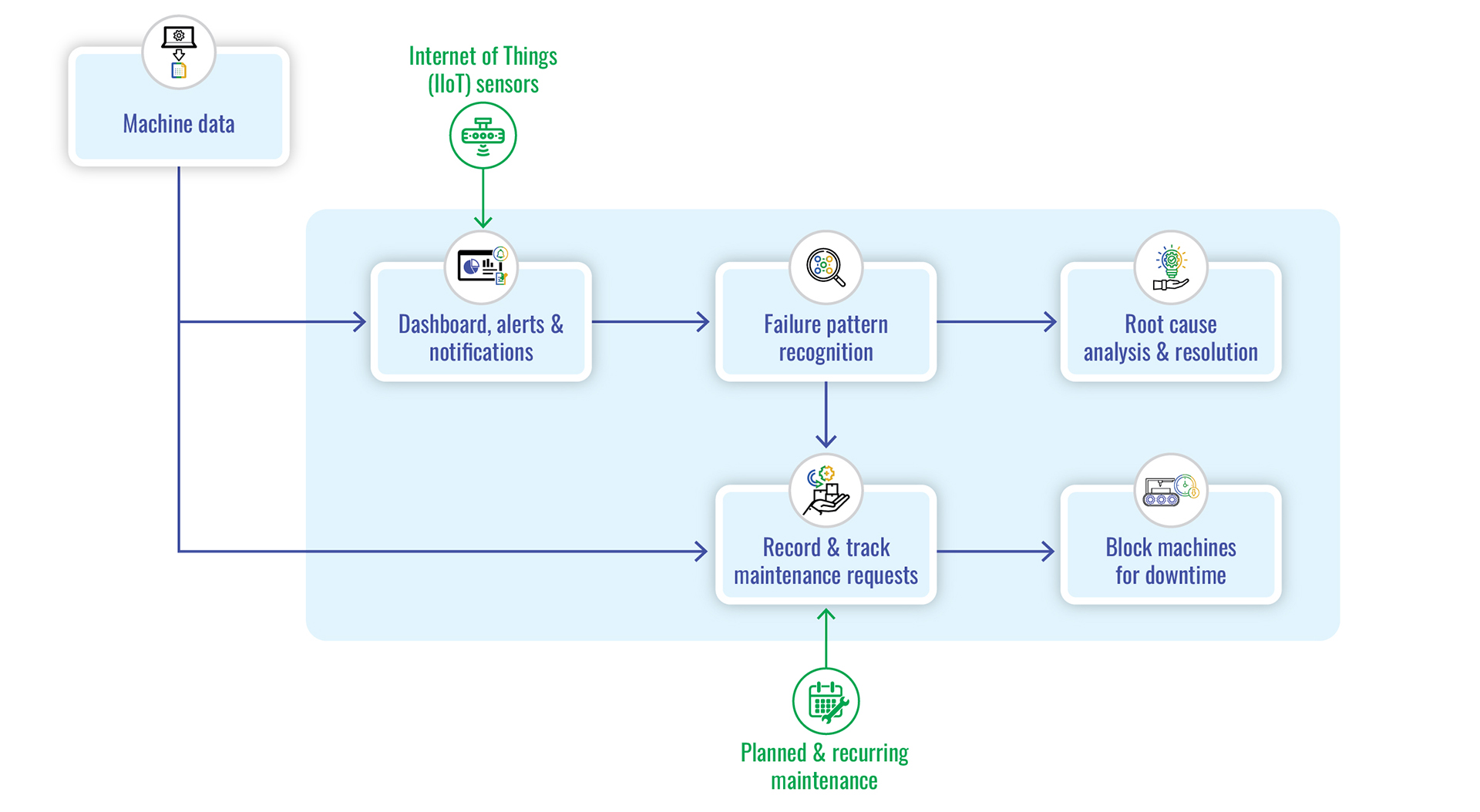

Elevate shop floor performance with IIoT-enabled equipment maintenance schedules powered by sensor data

Maximize asset performance and optimize overall equipment effectiveness (OEE) by leveraging IoT sensors and devices to monitor health, availability and performance of your assets. Detect trends, identify anomalies, and schedule maintenance to ensure minimal hiccups in planned production schedules. Hitech i2i gives you full control over your maintenance operations and maximize production throughput.

Make the shift from reactive to proactive maintenance management.

Get in Touch →Multiple functionalities. Designed for every business need.

Drive manufacturing excellence with Hitech i2i’s customizable & configurable MES modules

Future-proof your assets against costly breakdowns

Make the move from reactive to proactive maintenance with smart predictive maintenance solutions.

Schedule a demo →