Client Profile.

The client is a wooden pellets manufacturer that uses saw dust as raw material to create wooden pellets. These pellets work as biofuel in burners, boilers and thermal fluid heaters. The manufacturing plant has a daily production capacity of 30 tons and deploys heavy machinery for grinding, pellet making and cooling processes.

Business Need.

The manufacturing production unit involved a series of production processes such as raw material segregation, drying, RM charging, grinding etc. running sequentially. The performance at each stage impacted the overall production process. Hence it was important to monitor the production process at each stage and plug gaps in real time.

Efficiency of each of the above processes was benchmarked against pre-defined ranges and KPIs such as motor running hours, plant up time, oil temperature, ampere, hertz, and pressure.

Some of the challenges of the current process included:

- Reliance on manual systems to record KPI-related data invited errors and incorrect actions.

- The machine/process data resting in silos limited a cohesive view into cross-functional production process parameters.

- Sharing of production process reports just once a day limited on-time, impacting motor health and production capacity.

The company partnered with Hitech to deploy a production process KPI monitoring system to digitally track/record KPIs across all production processes in real time in a connected environment.

Challenges.

When digitalizing the KPI monitoring system, the team faced challenges such as:

- Some of the Programmable Logic Control (PLC) devices were outdated and could not generate data in the required format or in a form that would be compatible for use.

- Some of the data in the machines was being entered manually and the team had to program the machines to create digital footprints of the data.

- There was no clarity on the list of KPIs that actually needed to be tracked for best results and the HitechDigital team had to first work on finalizing/zoning in on the KPIs that needed to be tracked along with ranges.

Solution.

Hitech installed an automated production KPI monitoring system that integrated disparate data sources resting across the plant site to enable a unified view into all production process parameters. The solution empowered:

- End-to-end real time visibility of all production process parameters.

- Instant alerts and notifications through SMS, email and web-based apps on breach of pre-set threshold values.

- Creation of automated daily process and production status reports.

Approach.

Assessment and Documentation of As-is Conditions:

Supported by a detailed in-person site assessment, the Hitech data engineers:

- Identified that devices like master PLC, Variable Frequency Drives (VFDs), and controllers functioned in siloes and were not connected in a single OT network.

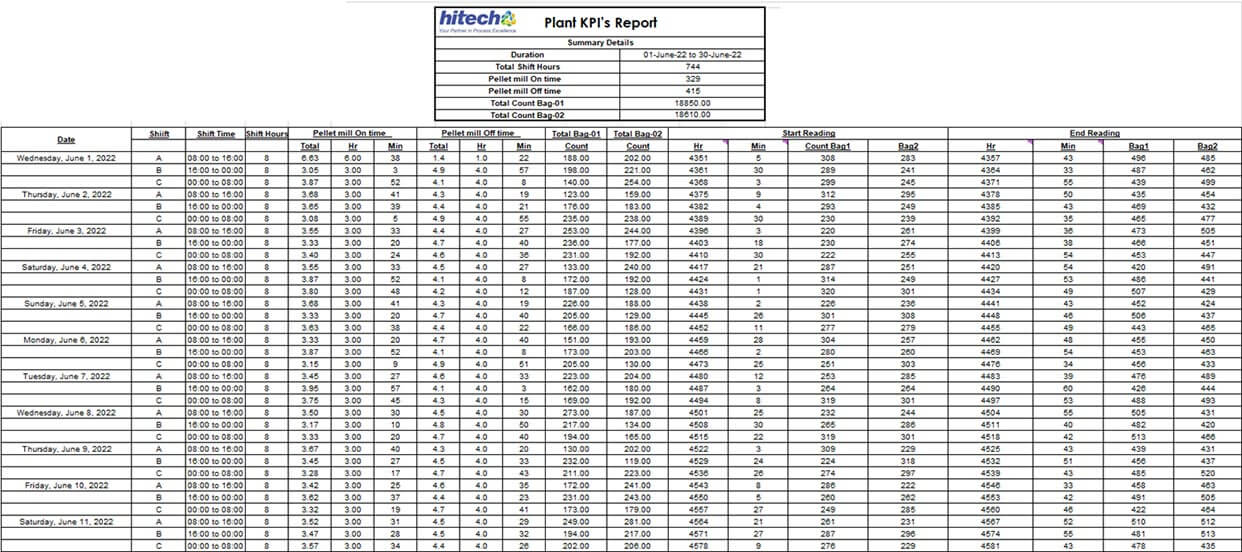

- Gathered permissible values for motor running hours, plant up time, oil temperature, ampere, Hz, pressure, total production bag counts etc.

- Defined a standardized format for reports and an easy-to-understand summary to be shared daily over email to all relevant users.

Deployment of Production KPI Monitoring System:

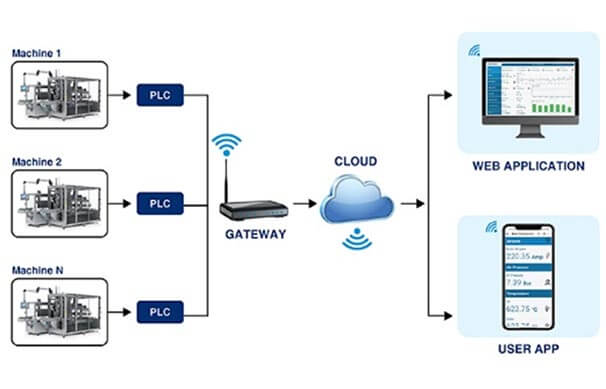

- Connected Master PLC, controllers and VFDs with IIoT gateway in the main control room to collect near real-time data from each device.

- Implemented a single daisy chain OT network to connect all devices, eliminate multiple data connections and continuously monitor critical process parameters.

- Defined upper and lower limits for process benchmarks to enhance performance to maintain the golden batch parameters.

- Created a web-based interactive dashboard for real-time visibility of exact status of critical process parameters across mobile devices. Generated and sent automated daily accurate reports for required KPIs through email to all relevant stakeholders.

- Raised instant alerts and notifications through web app, SMS and emails to respective owners on breach of threshold limit for any process parameter.

- The KPI Monitor focused on:

- Analyzing and interpreting process KPI data for actual plant uptime and downtime across the day, production output, etc.

- Giving 100% process visibility across the production floor.

- Providing data-based insights for evaluation of all production-related activities and take timely business decisions.

Tools and Technology Used

- IIoT platform, IIoT gateway, AWS and PostgreSQL

KPI Monitoring System Flow

KPI Monitoring System Flow

KPI Monitoring System

KPI Monitoring System

KPI Monitoring System Plant Report

KPI Monitoring System Plant Report