Client Profile.

Jet engine designer & manufacturer, USA

Industry: Automotive Industry

Objective.

A leading designer and manufacturer of jet engines had to validate the designs by studying the reacting flow by analyzing air-fuel mixture to attain optimum A-F ratio. HitechDigital CFD specialists simulated the flow patterns and combustion process using ANSYS Fluent to deliver the flow results and study outcomes for the manufacture in design modification – if need be.

Business Needs.

- Determination of optimum value of air-fuel ratio.

- Analyse various gases formation inside the combustor by combustion process.

- Measure the efficiency of jet engine and devise reliable performance with design optimization.

- Analyze the combustible pollutants i.e. CO2, NOx, soot, etc. during combustion.

Challenges.

- Creating and simulating reactive mixture of the fuel and air.

- Developing correct model for mesh with cut out outer wall for studying air flow.

- As combustion analysis needs expertise, it consumes extra time putting the CFD specialist under peer pressure of meeting deadlines.

- Simulating multiple values of air and fuel flow rates.

HitechDigital’s Solution.

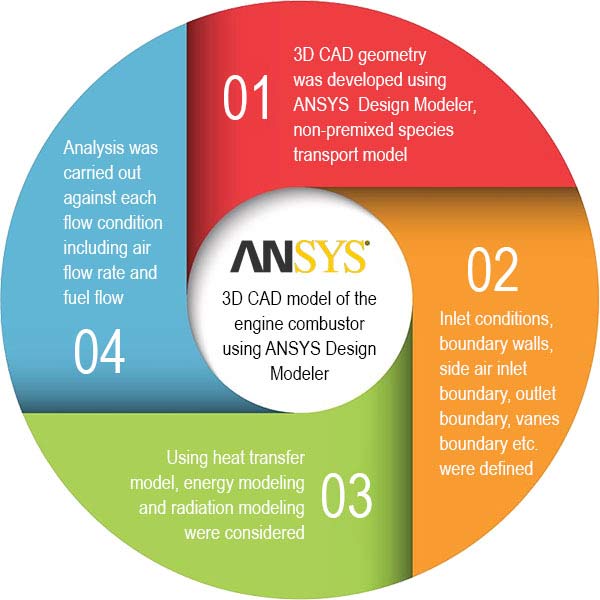

HitechDigital engineers developed a 3D CAD model of the engine combustor using ANSYS Design Modeler and simulated the flow pattern with combustion gases using ANSYS Fluent leveraging energy, heat transfer and radiation model. The final results of simulation were delivered to the client for his needs of design optimization and impacts on engine efficiency

Approach.

- 3D CAD geometry was developed using ANSYS Design Modeler, non-premixed species transport model was used to design the combustion process in the combustor design.

- Inlet conditions, boundary walls, side air inlet boundary, outlet boundary, vanes boundary etc. were defined clearly in ANSYS.

- Using heat transfer model, energy modeling and radiation modeling were considered and 20 different species were used for detailed combustion modeling.

- Analysis was carried out against each flow condition including air flow rate and fuel flow, along with fuel composition that were specified by the client.

Benefit.

- Expensive and precision manufacturing for jet engine were validated before any manufacturing began.

- Performance of the engine was optimized by optimizing the A-F ratio.

- Clean gas was achieved from exhaust of the combustor.

Client Speaks.

Easygoing and cooperative CFD specialists who are ready to go that extra lengths and help us achieve our targets by putting in all their knowledge and efficient skills of design analysis and validation.