A U.S.-based manufacturer specializing in metal and steel doors and frames, and selling its products through third-party retail distributors.

The company was shifting its focus to production and distribution, increasing its capacities to manufacture around 10,000 products a month, and manage smaller orders within 1-2 business days. The client approached HitechDigital, looking to significantly cut down on engineering activities, time and service costs.

Most customer orders involved custom design and manufacturing, which required between 6-12 hours of engineering design processes per order. And about 40% were small orders, increasing overall engineering time focused on personalizing requirements and in-depth quality checks for delivering on exact specifications.

Legacy systems used by the client were adding to overall order management time, especially in the movement and approval of design data and specifications from sales to engineering and production.

SOLIDWORKS®, DriveWorks®

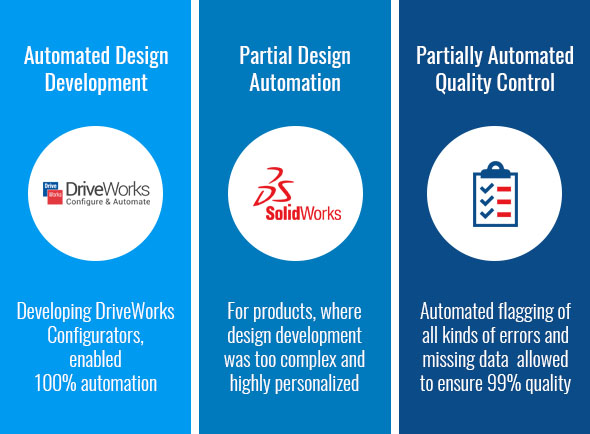

An authorized partner for DriveWorks implementation, HitechDigital’s engineers transformed the order to engineering and shop floor processes through automation solutions, reducing up to 80% of engineering time.

Automated design development for 70% of projects over 2 years

Through Sales Order Entry Services, developing DriveWorks Configurators, enabled 100% automation of

Partial design automation for rest of the projects

For products, where design development was too complex and highly personalized to be fully automated,

Partially automated Quality Control